Tool changing arm structure of tool changing magazine

A technology for changing tool arms and tool magazines, which is applied in the directions of manufacturing tools, clamping, and supports, and can solve the problems of increased vibration and wear of related components, reduced service life, accelerated elimination of related components, and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

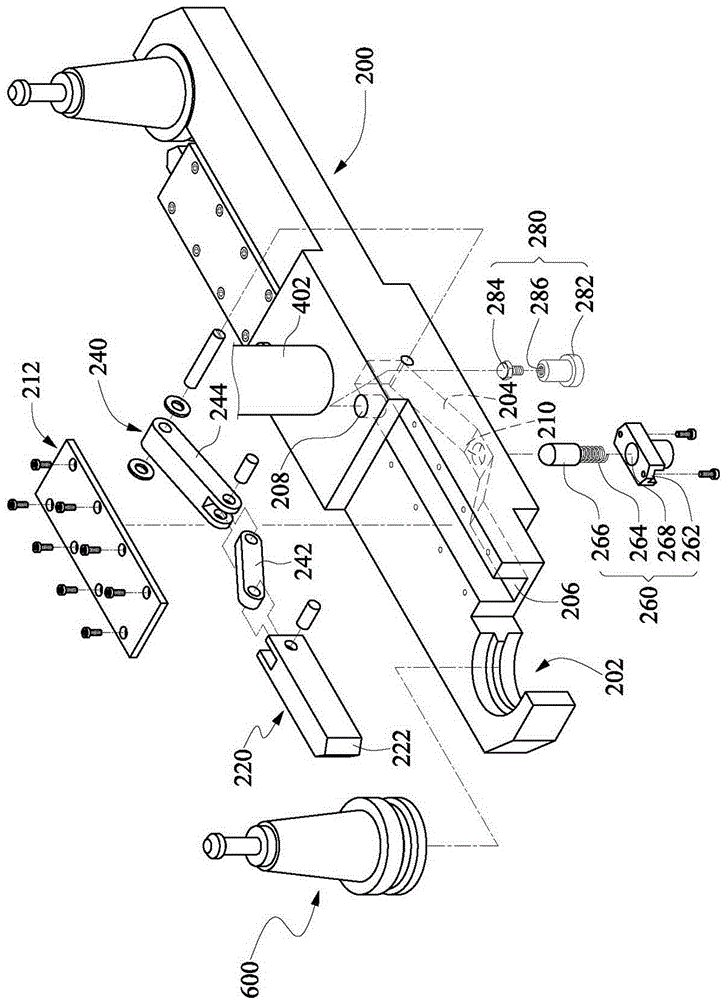

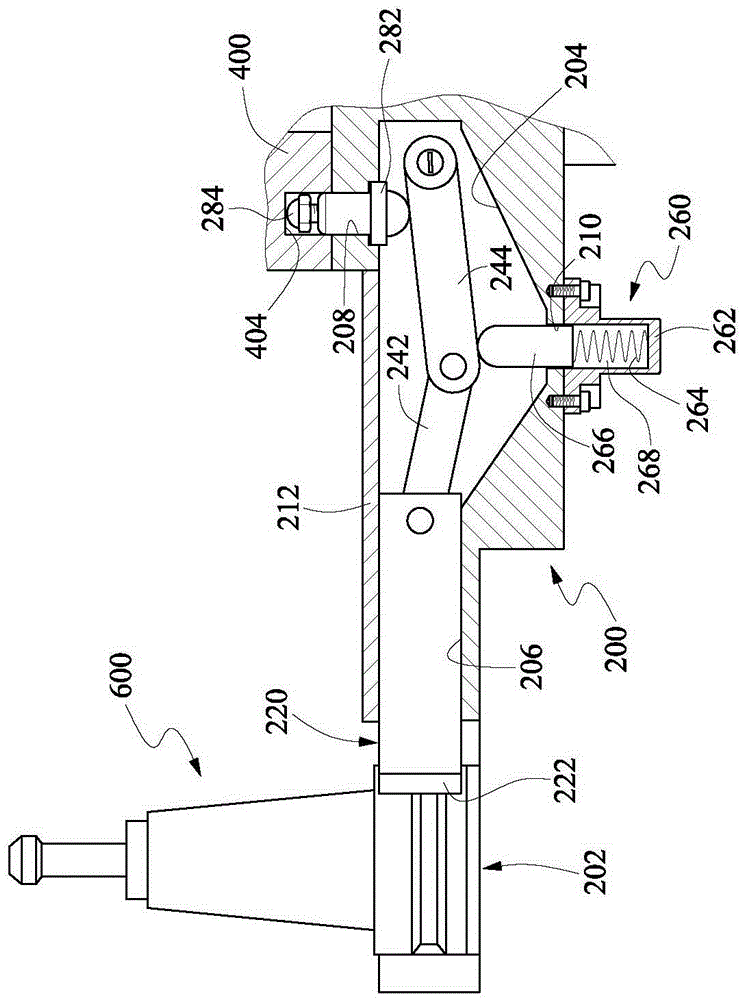

[0025] Hereinafter, please refer to the related drawings to further illustrate the embodiment of the tool changing arm structure of the tool changing tool magazine of the present invention. To facilitate the understanding of the embodiments of the present invention, the same components are described below with the same symbols.

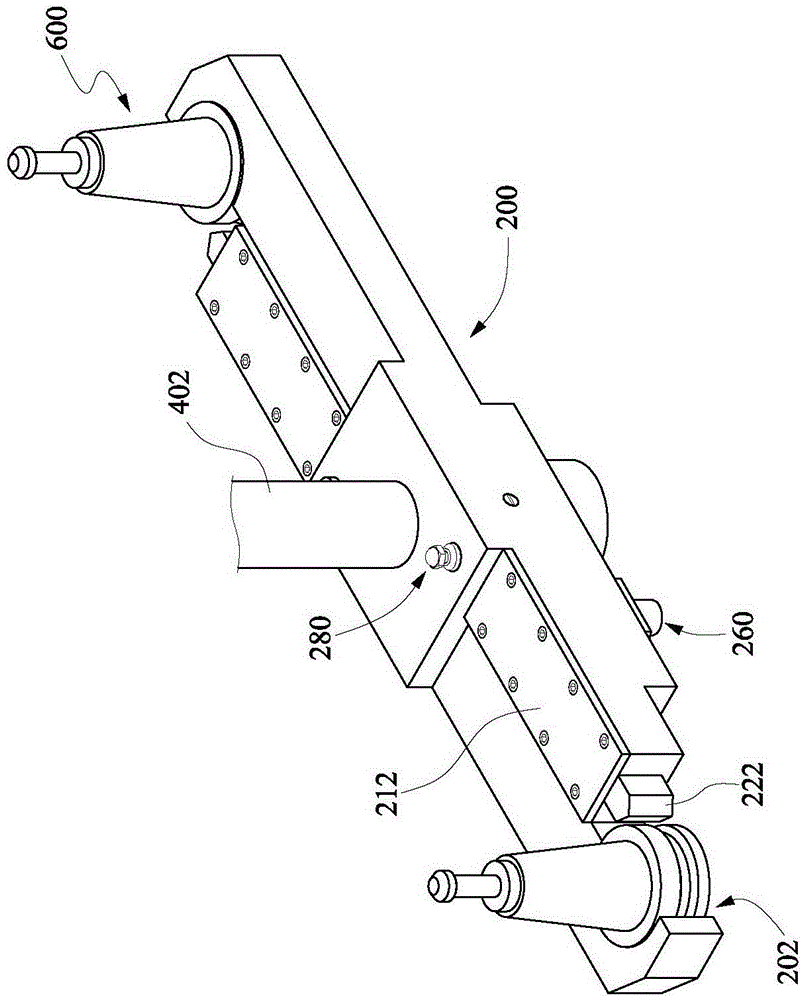

[0026] Please refer to Figure 1 to Figure 6 As shown in the figure, the tool changing arm structure of the tool changing tool magazine includes: a tool changing arm 200 and at least one buckling block 220 arranged on the tool changing arm 200, a crank connecting rod group 240, a first ejector group 260 , the second pusher group 280 and the pressing plate 212 . By means of the interaction between the first push-up group 260, the second push-up group 280 and the crank-connecting rod group 240, the engaging block 220 of the crank-connecting rod group is displaced in linkage, so that the tool changer arm 200 buckles the tool bar 600 At this time, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com