Screening method for consistent matching of lithium-ion batteries using voltage recovery voltage difference

A lithium-ion battery, voltage recovery technology, applied in sorting and other directions, can solve the problems that affect the capacity and cycle life of the battery pack, the battery cannot be charged and discharged at the same time, and the operation is complicated, and achieves good application prospects, high screening efficiency, and screening. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in conjunction with the following examples and accompanying drawings.

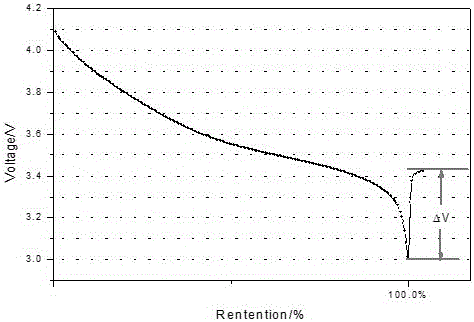

[0032] The present invention utilizes the voltage recovery pressure difference to carry out the screening method of lithium-ion battery consistent matching group, such as figure 1 shown, including the following steps:

[0033] (1) Pre-testing:

[0034] Perform performance testing on the manufactured batteries in advance, and eliminate unqualified batteries;

[0035] (2) Charge and discharge the batteries to be sorted in stages, and record the voltage change value of each stage:

[0036] 1) Constant current and constant voltage charging:

[0037] Charge the battery to be sorted with a constant current and constant voltage of 0.5C to 4.2V, with a cut-off current of 0.02C and a time limit of 180min;

[0038] 2) Set aside for 5 minutes;

[0039] 3) Constant current discharge:

[0040] Discharge to 3.0V with a constant current of 0.5C, and the time li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com