Self-lubricating gasket bonding method

A self-lubricating and gasketing technology, which is applied in the bonding field of self-lubricating gaskets, can solve problems such as uneven coating of adhesives, poor ability of phenolic resin to bond metal, and inability to adapt, so as to reduce manual coating. Disturbance of uniformity, small fluctuation of peel strength, uniform distribution of adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for bonding a self-lubricating liner provided by the invention comprises steps:

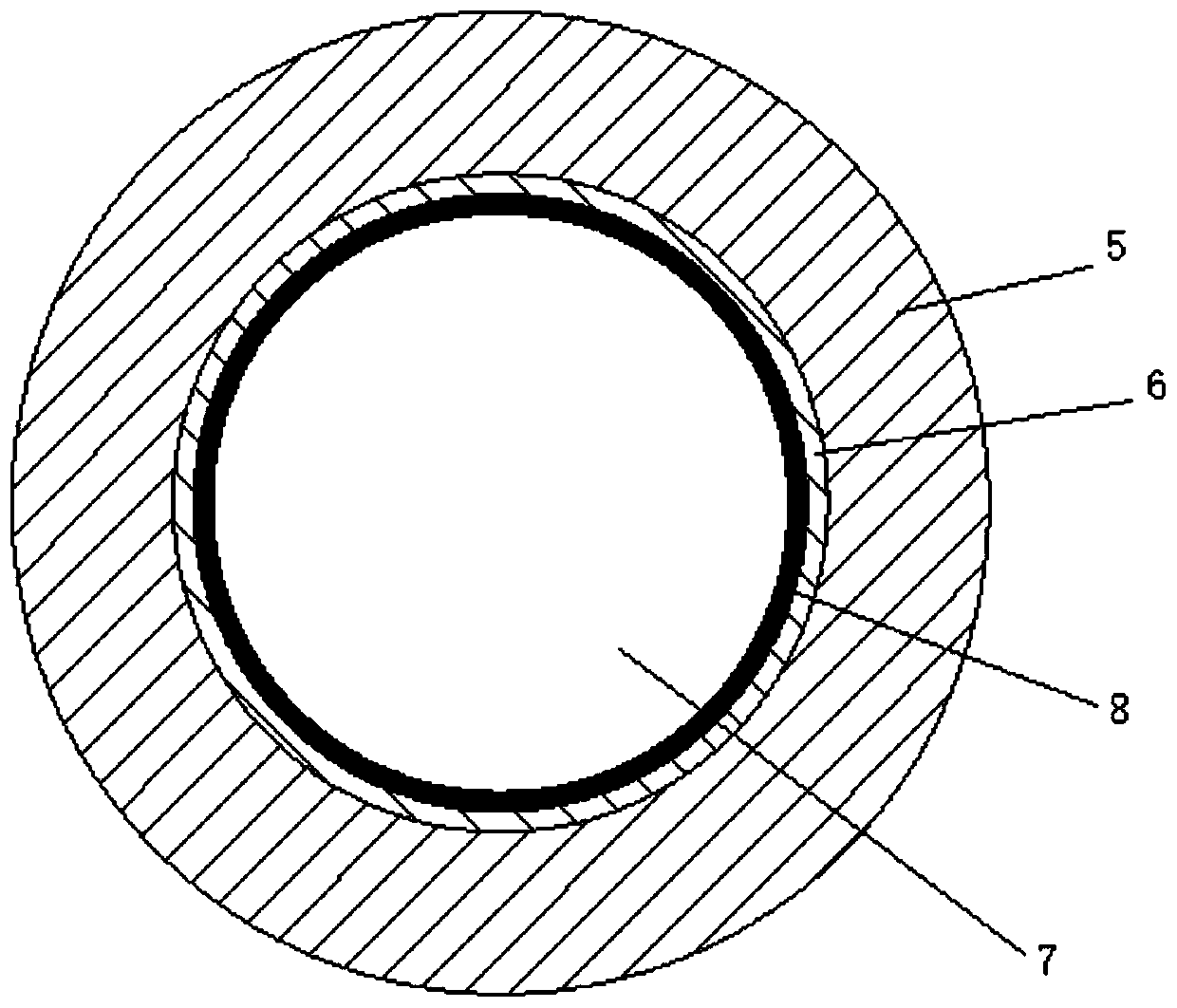

[0033] S1: Metal surface treatment: sandblasting the inner surface of bearing outer steel ring 5, after sandblasting, use organic solvent to clean the metal surface, dry it, and set it aside;

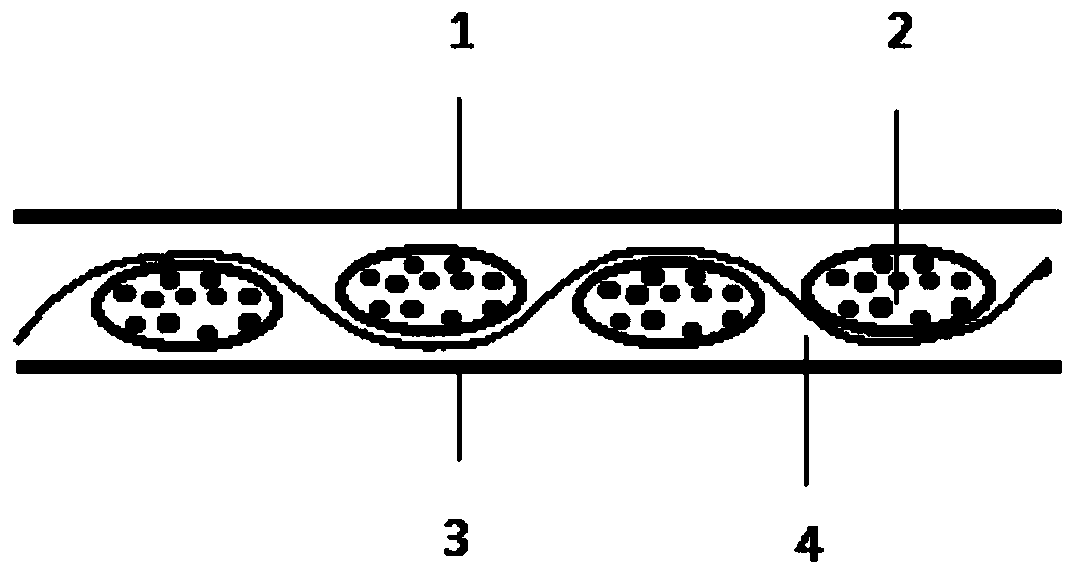

[0034] S2: tear off the first PTFE non-adhesive film 1 of the glass fiber prepreg double-sided structural adhesive;

[0035] S3: bonding one side of the first PTFE non-adhesive film 1 of the glass fiber prepreg double-sided structural adhesive to the adhesive surface of the liner 8, thereby forming an adhesive layer 6 on the adhesive surface;

[0036] S4: After the two are bonded together, carry out hot pressing with a flat vulcanizing machine to make the two closely bonded. The hot pressing temperature is 80°C, the pressure is 2 MPa, and the pressure holding time is 4 minutes;

[0037] S5: Cut the heat-compressed liner 8 into a suitable size according to the size of the outer steel ring 5...

Embodiment 2

[0041] This embodiment relates to a new bonding process of a self-lubricating liner, comprising the following steps:

[0042] S1: metal surface treatment: same as embodiment 1;

[0043] S2: Same as Example 1, the first PTFE non-adhesive film 1 of the glass fiber prepreg double-sided structural adhesive is torn off;

[0044] S3: As in Example 1, the side of the first PTFE non-adhesive film 1 of the glass fiber prepreg double-sided structural adhesive is bonded to the gasket bonding surface;

[0045] S4: After the two are pasted together, hot press with a flat vulcanizing machine to make the two fit closely. The hot pressing temperature is 100°C, the pressure is 2 MPa, and the pressure holding time is 8 minutes;

[0046] S5: Same as in Example 1, the heat-compressed liner is cut into a suitable size according to the size of the outer steel ring 5 of the bearing;

[0047] S6: Same as in Example 1, tear off the non-adhesive film 2 of the double-sided structural adhesive of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com