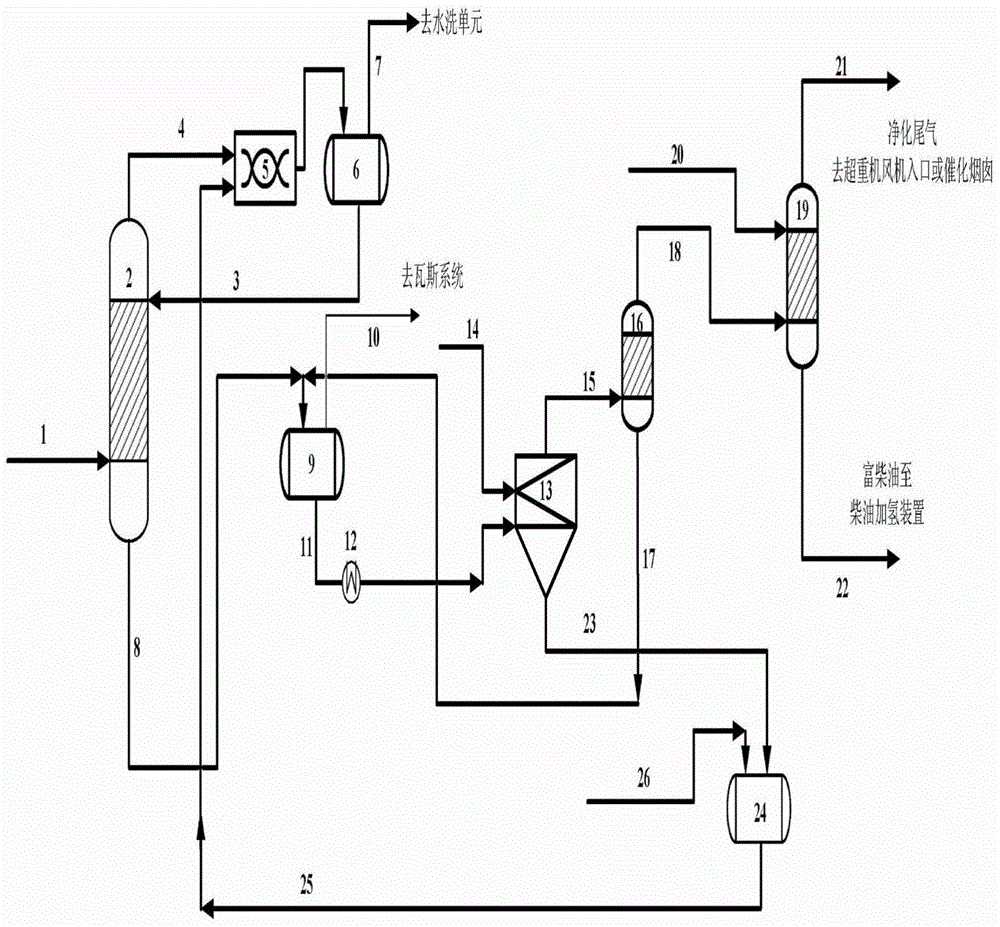

Combination method for deep desulfurization of liquefied gas

A combined method and deep desulfurization technology, applied in chemical instruments and methods, separation methods, gas fuels, etc., can solve the problems of insufficient oxidation, large consumption of lye, and reduced extraction capacity, and achieve clean and deep desulfurization. Tall and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] In the lye regeneration scale-up test with a lye treatment capacity of 50L / h, the lye regeneration test and tail gas absorption test were carried out at the same time. In the lye regeneration test, the gas-liquid volume ratio ranges from 1 to 1500:1, and the reaction temperature is 20 to 70°C. In the tail gas absorption test, the diesel flow rate is 0.5-5L / h, and the reaction temperature is 20-40°C.

[0028] The lye is introduced into the heating tank from the storage tank, and is pumped into the supergravity reactor after heat exchange with steam, and the air is sent into the supergravity reactor by the fan. Air and waste lye are mixed in the overweight machine, the tail gas is separated by the liquid catcher and then enters the absorption device, and the regenerated lye is sampled and stored in a 1m3 barrel. The flow of lye is controlled by a rotameter and a bypass valve, the air flow is controlled by a rotameter, and the speed of the overweight machine is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com