A kind of gasoline desulfurizer and its preparation method and application

A desulfurizer and gasoline technology, applied in the petroleum industry, treating hydrocarbon oil, refining with non-metals, etc., can solve the problems of octane number loss, poor regeneration performance, etc., and achieve good regeneration performance, low production cost, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

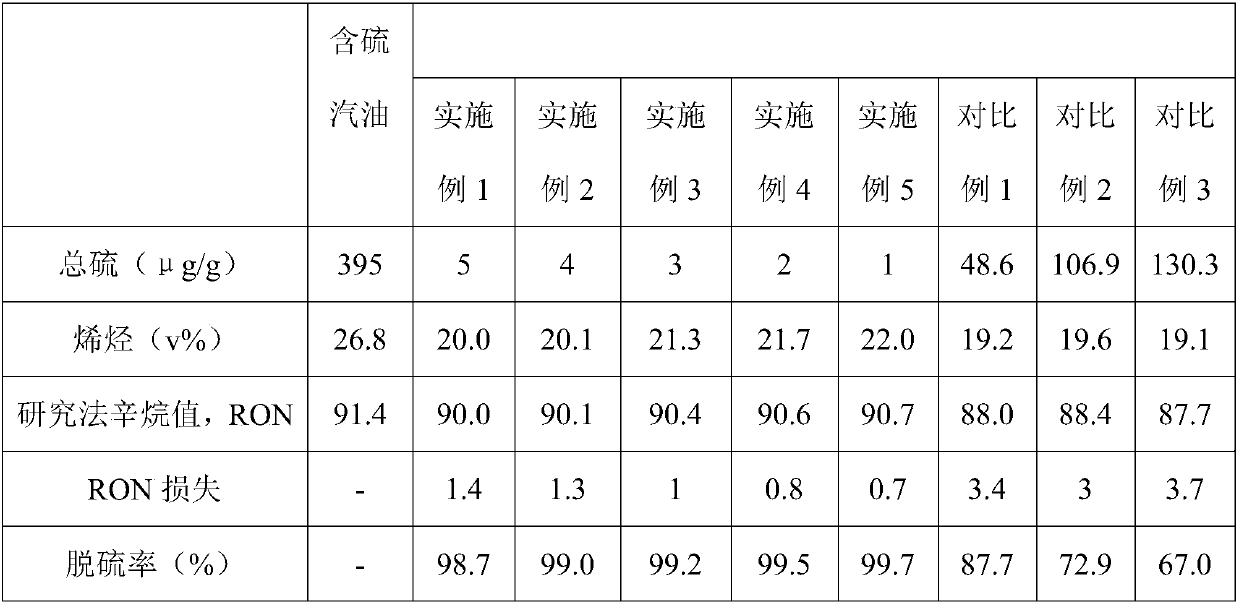

Examples

Embodiment 1

[0017] In the embodiment of the present invention, a gasoline desulfurizer is composed of the following raw materials in parts by weight: 21 parts of illite, 1 part of perillyl alcohol, 3 parts of salicylic acid, and 5 parts of triethylenediamine.

[0018] Triethylenediamine is mixed with 8.2 times the mass of ethanol with a volume concentration of 50% to prepare a triethylenediamine solution; perillyl alcohol is mixed with 1.1 times the mass of ethanol to prepare a perillyl alcohol solution. The illite was crushed and passed through a 120-mesh sieve, and then the triethylenediamine solution was added. The temperature was raised to 73°C and sealed and stirred for 2.2h at this temperature. Then the temperature was raised to 88°C and salicylic acid was added dropwise. Ultrasonic treatment at temperature for 37 minutes, ultrasonic power of 900W, add perillyl alcohol solution and stir to dryness at a temperature of 99°C, and then calcinate in a muffle furnace at 440°C for 3.8 hours to...

Embodiment 2

[0020] In the embodiment of the present invention, a gasoline desulfurizer is composed of the following raw materials in parts by weight: 29 parts of illite, 5 parts of perillyl alcohol, 7 parts of salicylic acid, and 12 parts of triethylenediamine.

[0021] Triethylenediamine is mixed with 8.2 times the mass of 50% ethanol to prepare a triethylenediamine solution; perillyl alcohol is mixed with 1.1 times the mass of ethanol to prepare a perillyl alcohol solution. The illite was crushed and passed through a 120-mesh sieve, and then the triethylenediamine solution was added. The temperature was raised to 73°C and sealed and stirred for 2.2h at this temperature. Then the temperature was raised to 88°C and salicylic acid was added dropwise. Ultrasonic treatment at temperature for 37 minutes, ultrasonic power of 900W, add perillyl alcohol solution and stir to dryness at a temperature of 101°C, and then calcinate in a muffle furnace at 440°C for 3.8 hours to obtain a desulfurizer.

Embodiment 3

[0023] In the embodiment of the present invention, a gasoline desulfurizer is composed of the following raw materials in parts by weight: 23 parts of illite, 2 parts of perillyl alcohol, 4 parts of salicylic acid, and 7 parts of triethylenediamine.

[0024] Triethylenediamine is mixed with 8.2 times the mass of 50% ethanol to prepare a triethylenediamine solution; perillyl alcohol is mixed with 1.1 times the mass of ethanol to prepare a perillyl alcohol solution. The illite was crushed and passed through a 120-mesh sieve, and then the triethylenediamine solution was added. The temperature was raised to 73°C and sealed and stirred for 2.2h at this temperature. Then the temperature was raised to 88°C and salicylic acid was added dropwise. Ultrasonic treatment at temperature for 37 minutes, ultrasonic power of 900W, add perillyl alcohol solution and stir to dryness at 100°C, then calcinate in a muffle furnace at 440°C for 3.8 hours to obtain desulfurizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com