A kind of production method of desulfurized gasoline

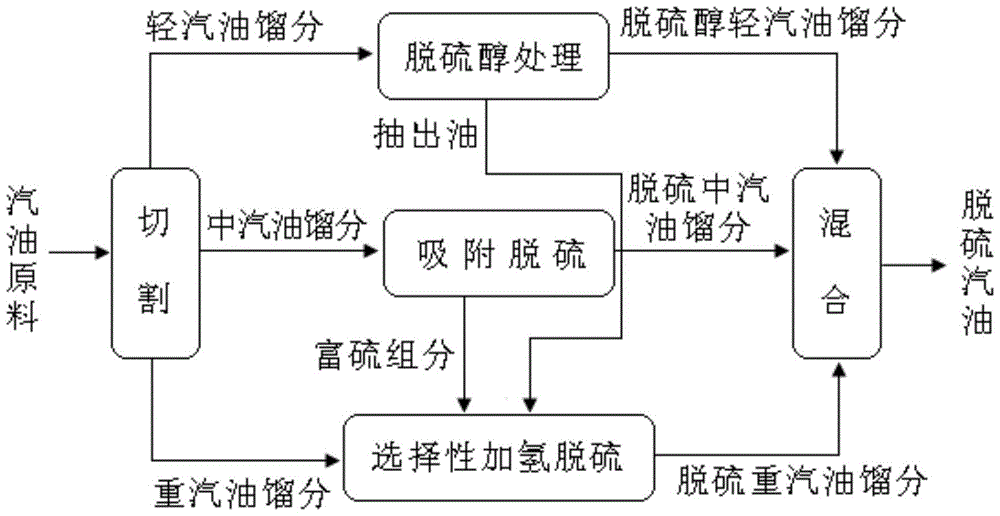

A production method and gasoline technology, applied in chemical instruments and methods, processing hydrocarbon oil, petroleum industry, etc., can solve the problems of octane number loss, limited desulfurization depth, etc. The effect of sub-content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Preparation of desulfurization adsorbent

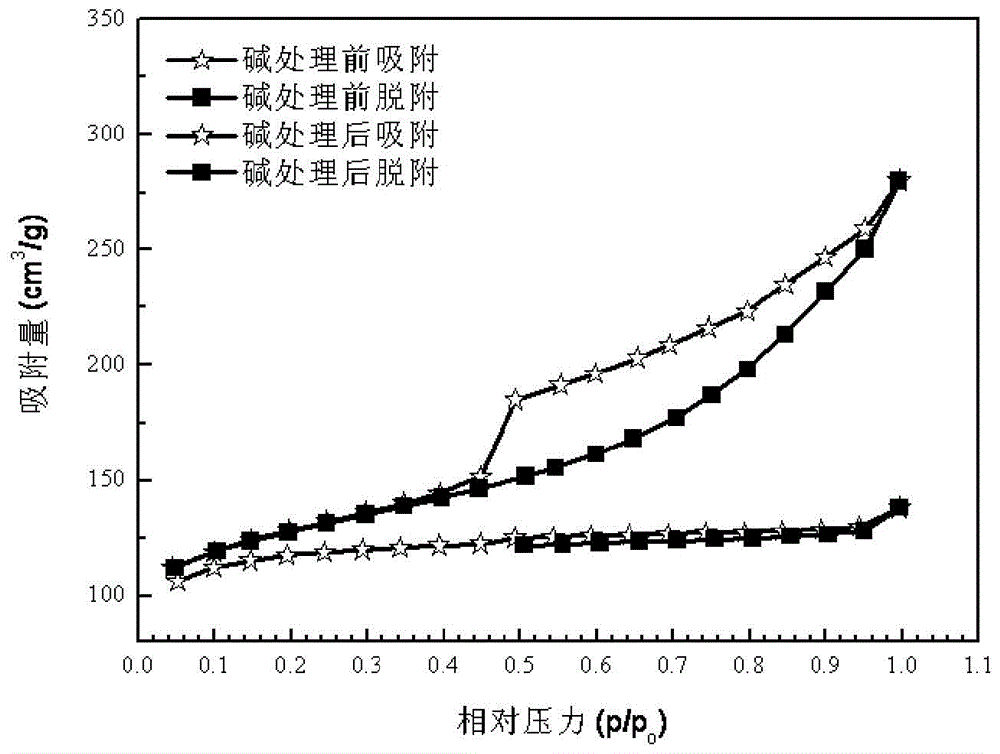

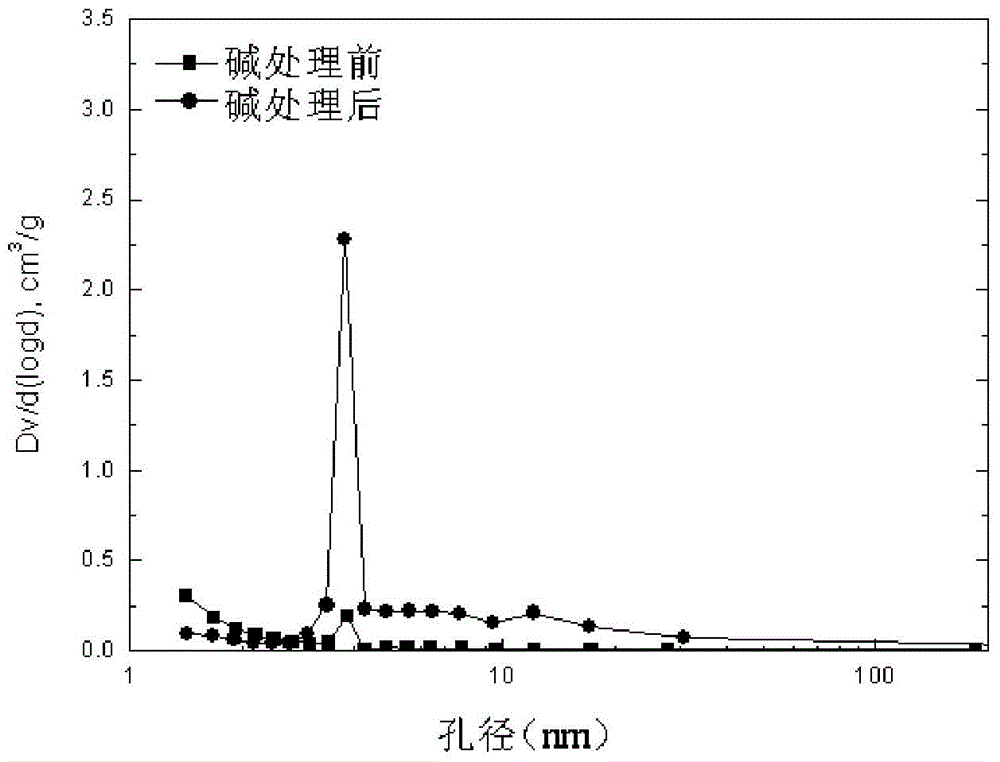

[0063] 1) Preparation of alkali-treated molecular sieve and activated carbon

[0064] After heating two 500 mL NaOH solution water baths with a concentration of 0.3 mol / L to about 70 °C, 25 g of ZSM-5 molecular sieve and 25 g of activated carbon were added to them, and after stirring for about 200 minutes, the mixture was immediately cooled in an ice bath. To room temperature, filter and filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then the obtained filter cake is placed in an oven at 110 ° C and dried for 4 hours to obtain alkali-treated ZSM- Type 5 molecular sieve and activated carbon treated with alkali; among them, the adsorption and desorption isotherms and pore size distribution curves of ZSM-5 type molecular sieve before and after alkali treatment are shown in figure 1 and figure 2 .

[0065] In addition, the specific surface area and pore si...

Embodiment 2

[0092] 1. Preparation of desulfurization adsorbent

[0093] 1) Preparation of alkali-treated molecular sieve and activated carbon

[0094] After raising the temperature of two 500mL NaOH solutions with a concentration of 0.2mol / L in a water bath to about 80°C, add 25g of Y-type molecular sieve and 25g of activated carbon to them respectively, stir for about 120 minutes, and immediately cool the mixture to room temperature in an ice bath , filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then place the obtained filter cake in an oven at 120°C for 3 hours to obtain alkali-treated Y-type molecular sieve and The specific surface area and pore size distribution of alkali-treated activated carbon; Y-type molecular sieve and activated carbon are shown in Table 3.

[0095] Table 3 Specific surface area and pore size of Y-type molecular sieve and activated carbon

[0096]

[0097] 2) Preparation of composite carr...

Embodiment 3

[0117] 1. Preparation of desulfurization adsorbent

[0118] 1) Preparation of alkali-treated molecular sieve and activated carbon

[0119]After two 500mL NaOH solution water baths with a concentration of 0.2mol / L were heated to about 70°C, 25g of ZSM-5 molecular sieves and 25g of activated carbon were respectively added to them, and after stirring for about 90 minutes, the mixture was immediately cooled in an ice bath. To room temperature, filter and filter and wash the filter cake with deionized water for several times, until the pH value of the filtrate is about 7, the obtained filter cake is placed in an oven at 120 ° C for drying for 3 hours;

[0120] The obtained ZSM-5 molecular sieve and the activated carbon are respectively repeated the above steps once (that is, the alkali treatment is twice) to obtain the alkali treated ZSM-5 molecular sieve and the alkali treated activated carbon; ZSM-5 molecular sieve and activated carbon are obtained. The specific surface area and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com