A high-temperature gas-solid filtration and separation device

A technology of filtration separation and high-temperature gas, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of hindering the falling of dust and insufficient dust removal efficiency, so as to prolong the service life, reduce equipment maintenance costs, and increase resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

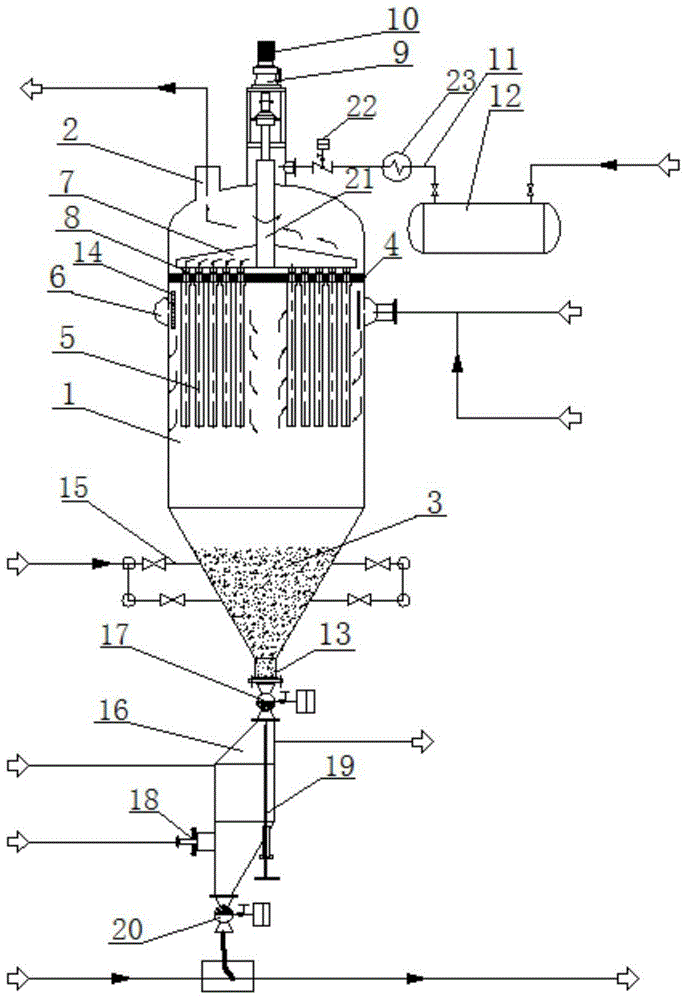

[0041] Such as figure 1 and figure 2 As shown, this embodiment provides a high-temperature gas-solid filtration and separation device used in the production of melamine. In the melamine production device, the temperature of the reaction gas from the catalytic reactor is about 400 ° C. The gas contains catalyst particles and by-product dust. Also contains flammable and toxic ammonia gas.

[0042] The high-temperature gas-solid filtration and separation device includes a filter body 1 with a clean gas outlet 2 on the top, an ash hopper 3 on the bottom, and a dust outlet 13 at the bottom of the ash hopper 3; the ash hopper 3 is arranged around the outside There is a loosening wind input device 15, and the loosening wind input device 15 includes 3 branch pipes evenly distributed around the ash hopper 3 and communicated with the ash hopper 3;

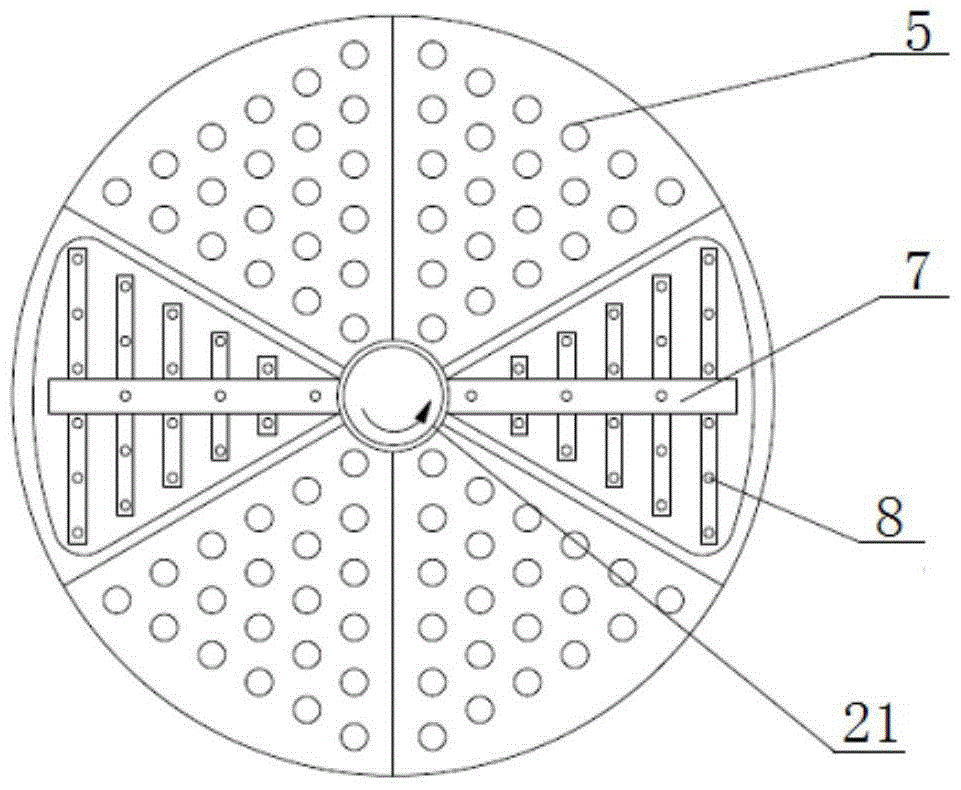

[0043] The flower plate 4 is erected on the upper part of the inner cavity of the filter body 1, and divides the filter body 1 into an u...

Embodiment 2

[0057] Such as figure 1 and figure 2 As shown, this embodiment provides a high-temperature gas-solid filtration and separation device used in the methanol-to-gasoline fluidized-bed process. In the methanol-to-gasoline fluidized-bed process, the temperature of the reaction product gas from the catalytic reactor is about 380°C, which is alkane , olefins, aromatics and other explosive gases, which contain catalyst dust particles, and there are carbon deposits and coking on the surface and interior of the catalyst particles.

[0058] The high-temperature gas-solid filtration and separation device is used in parallel with two separation devices. Each filter device includes a filter body 1 with a clean gas outlet 2 on the top, an ash hopper 3 on the bottom, and an ash hopper 3 at the bottom. Dust outlet 13; the outside of the ash hopper 3 is provided with a loose wind input device 15, and the loose wind input device 15 includes four branch pipes that are evenly distributed around ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com