Preparation method of polymaleic anhydride-phosphatidyl ethanolamine graft polymer nano-photosensitive carrier

A technology of phosphatidylethanolamine and polymaleic anhydride, which is applied in the field of medicine, can solve the problems of limiting the further application of photodynamic therapy, strong hydrophobicity of photosensitizer, and low utilization rate of drugs, and achieve high drug loading efficiency, short preparation cycle, The effect of simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

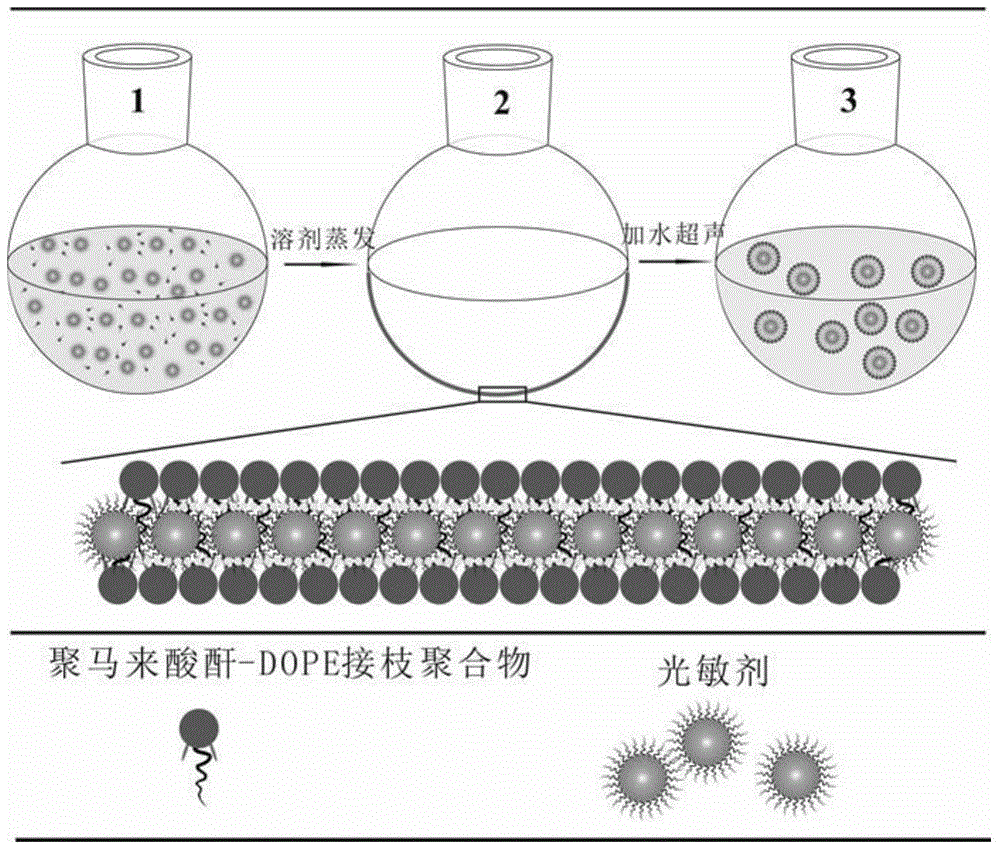

[0034] Synthesis of polymaleic anhydride-phosphatidylethanolamine graft polymer:

[0035] (1) The mass ratio of the raw materials is as follows: 100 mg of poly(1-octadecene / maleic anhydride) and 1000 mg of fatty acylethanolamine are weighed and added to the reactor. Under magnetic stirring conditions, add solvent tetrahydrofuran (THF) into the reactor to completely dissolve the raw materials. Heated to 70°C, condensed and refluxed for 2 days.

[0036] (2) After the reaction is finished, lower the temperature and put the product into a dialysis bag for dialysis for 3 days. The dialyzed solution was filtered and freeze-dried to obtain an amphiphilic polymaleic anhydride-phosphatidylethanolamine graft polymer, and the graft ratio of the prepared polymer was 22.6%.

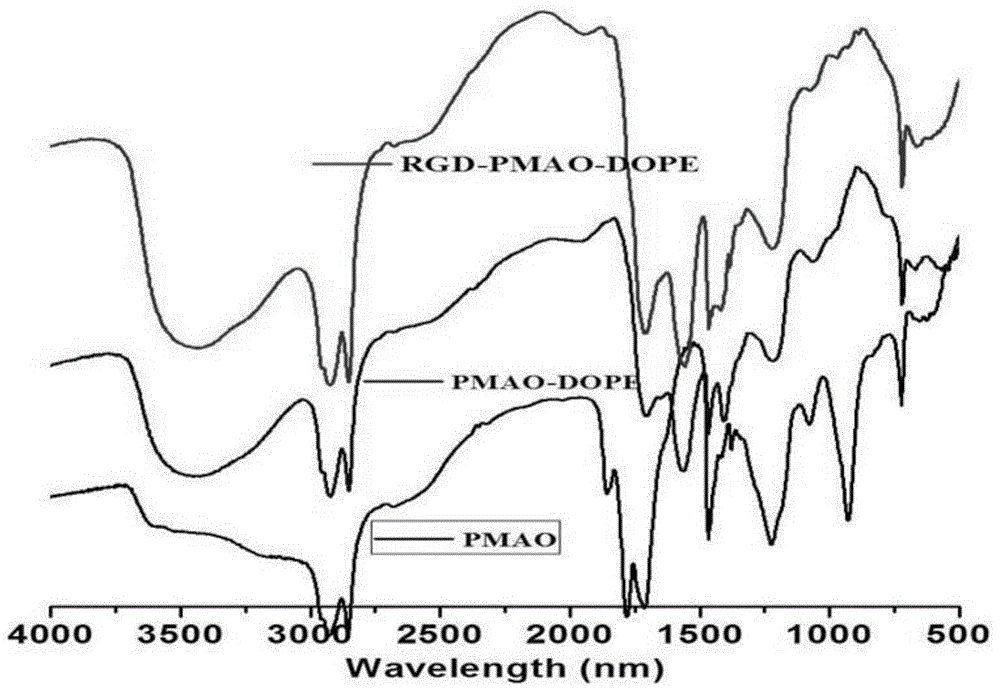

[0037] figure 2 : according to the synthetic polymaleic anhydride-phosphatidylethanolamine graft polymer infrared spectrogram of embodiment 1.

Embodiment 2

[0039] Synthesis of polymaleic anhydride-phosphatidylethanolamine graft polymer:

[0040] (1) The mass ratio of the raw materials is as follows: 50 mg of poly(1-octadecene / maleic anhydride) and 1000 mg of fatty acylethanolamine are weighed and added to the reactor. Under magnetic stirring conditions, add solvent tetrahydrofuran (THF) into the reactor to completely dissolve the raw materials. Heated to 30°C, condensed and refluxed for 3 days.

[0041] (2) After the reaction is finished, lower the temperature and put the product into a dialysis bag for dialysis for 7 days. The dialyzed solution was filtered and freeze-dried to obtain an amphiphilic polymaleic anhydride-phosphatidylethanolamine graft polymer, and the graft ratio of the prepared polymer was 10%.

Embodiment 3

[0043] Synthesis of polymaleic anhydride-phosphatidylethanolamine graft polymer:

[0044] (1) The mass ratio of the raw materials is as follows: 200 mg of poly(1-octadecene / maleic anhydride) and 6000 mg of fatty acylethanolamine are weighed and added to the reactor. Under magnetic stirring conditions, add solvent tetrahydrofuran (THF) into the reactor to completely dissolve the raw materials. Heated to 46°C, condensed and refluxed for 1 day.

[0045] (2) After the reaction is finished, lower the temperature and put the product into a dialysis bag for dialysis for 5 days. The dialyzed solution was filtered and freeze-dried to obtain an amphiphilic polymaleic anhydride-phosphatidylethanolamine graft polymer, and the graft ratio of the prepared polymer was 30%.

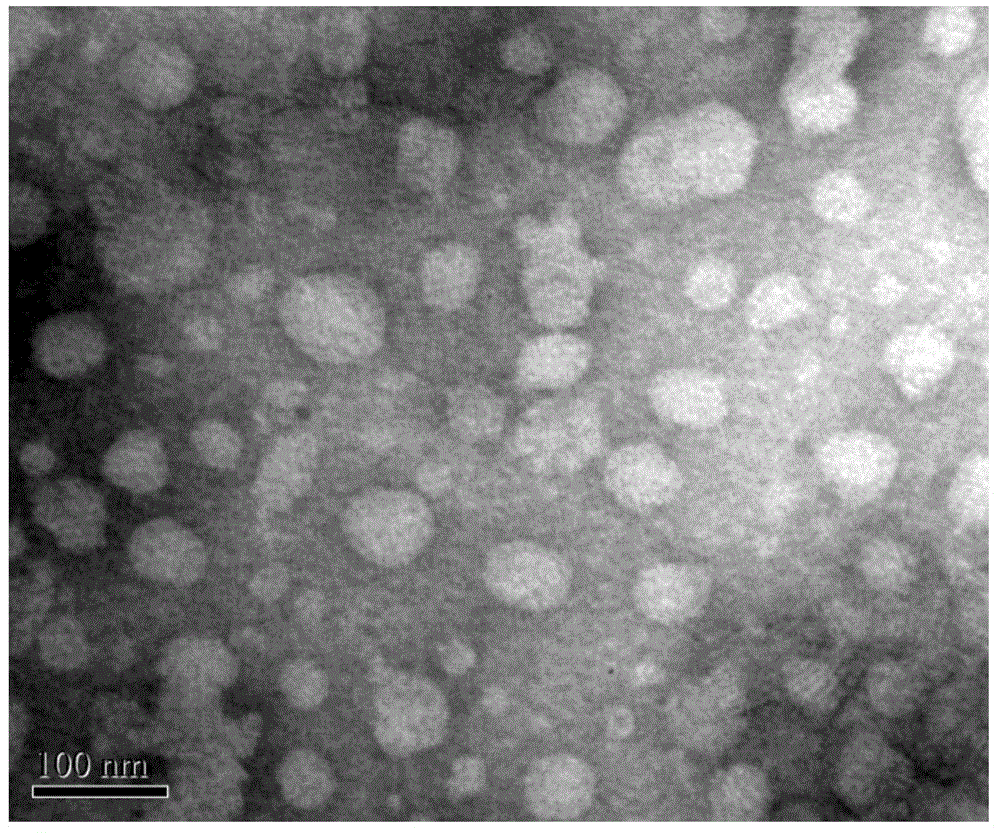

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com