Method for protective treatment of lithium cathodes in lithium secondary batteries

A protective layer and treatment liquid technology, which is applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve problems such as discounts and complicated preparation methods, achieve improved cycle performance, simple preparation methods, and suitable for large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, the preparation of metallic lithium in-situ protective layer

[0027] In a high-purity argon atmosphere, immerse the lithium sheet in tetraethyl orthosilicate and react for 90s at a reaction temperature of 35°C. After taking out the lithium sheet and wiping off the excess orthosilicate liquid on the surface, the SiO provided by the invention can be obtained. 2 The protective layer.

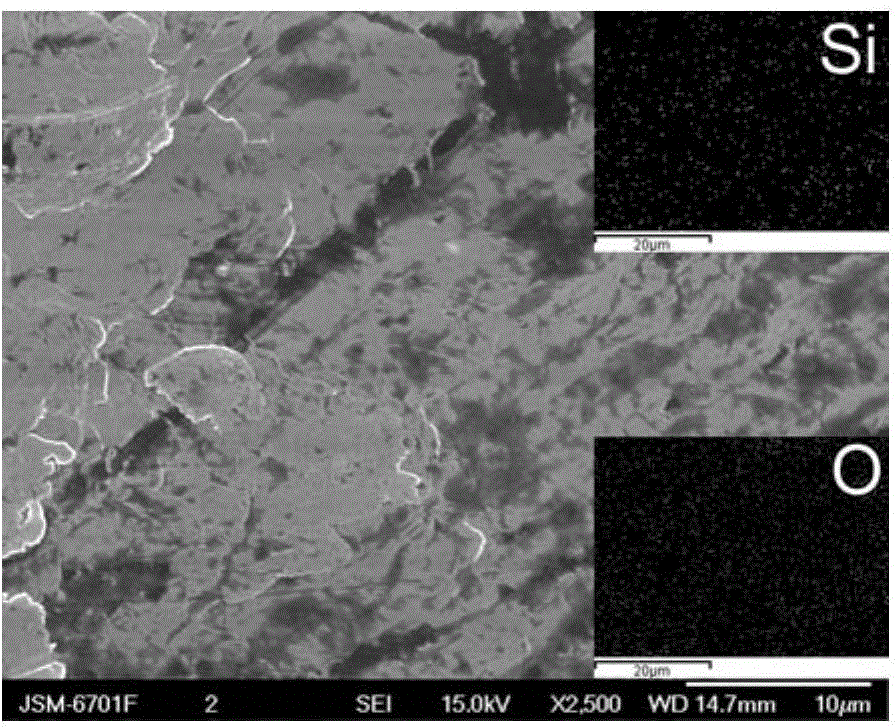

[0028] Observation of SiO with Cold Field Emission Scanning Electron Microscopy (SEM) 2 The morphology of the protective layer, such as figure 1 As shown, the inset is the Mapping picture of the corresponding silicon and oxygen elements. It can be seen from the figure that silicon elements and oxygen elements are evenly distributed on the protective layer. In addition, it can be seen from the cross-sectional view of SEM that SiO 2 The thickness of the protective layer was 150 nm. .

[0029] This kind with SiO 2 The deposition and stripping potential and impedance test r...

Embodiment 2

[0030] Embodiment 2, the preparation of metallic lithium in-situ protective layer

[0031] In a high-purity helium atmosphere, add tetraethyl orthosilicate liquid dropwise on the surface of the lithium sheet, the reaction temperature is 40°C, react for 300s, wipe off the excess tetraethyl orthosilicate liquid on the surface, and the SiO provided by the invention can be obtained. 2 The protective layer.

[0032] Compared with Example 1, the inert atmosphere was changed to helium, the amount of tetraethyl orthosilicate was greatly reduced, and it was dropped on the surface of the lithium sheet instead, and the reaction time was changed to 300s.

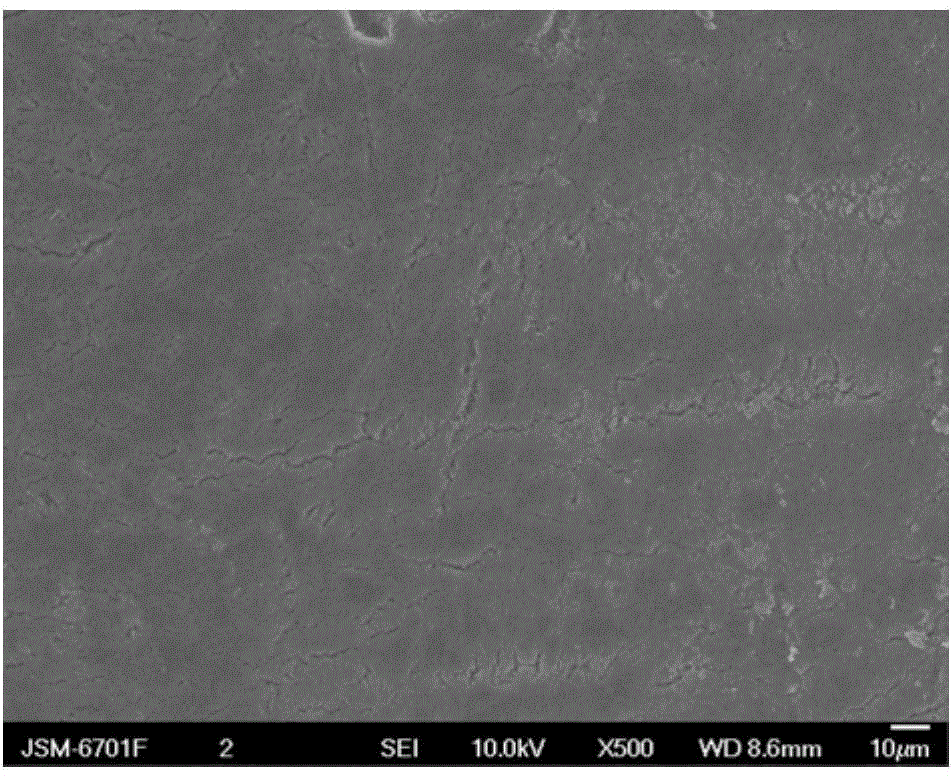

[0033] Observation of SiO with Cold Field Emission Scanning Electron Microscopy (SEM) 2 The morphology and structure of the protective layer, the lamellar structure is uniformly grown on the lithium surface, the elements are silicon and oxygen, and the thickness is 100nm.

[0034] This kind with SiO 2 The deposition and stripping pot...

Embodiment 3

[0035] Embodiment 3, the preparation of metallic lithium in-situ protective layer

[0036] Under a high-purity argon atmosphere, immerse the lithium sheet in trimethylchlorosilane and react for 200s at a reaction temperature of 40°C. After taking out the lithium sheet and wiping off the excess trimethylchlorosilane liquid on the surface, the SiO provided by the invention can be obtained. 2 The protective layer.

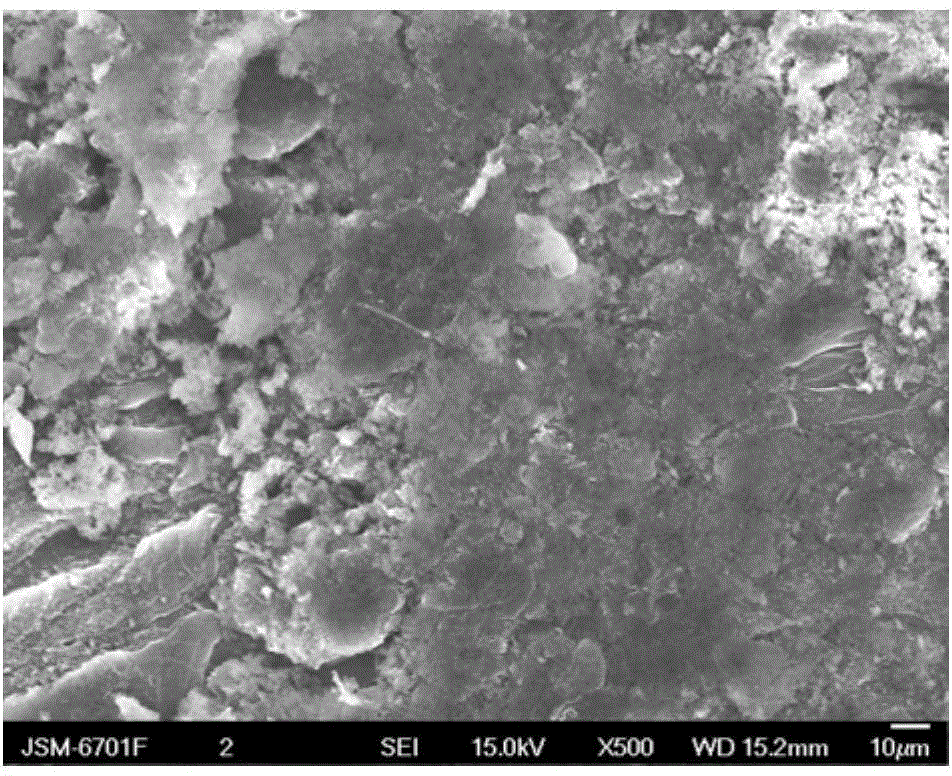

[0037] Observation of SiO with Cold Field Emission Scanning Electron Microscopy (SEM) 2The morphology of the structure is composed of a multi-layer sheet structure, and the constituent elements are silicon, oxygen and a small amount of chlorine. In addition, it can be seen from the cross-sectional view of SEM that SiO 2 The thickness of the protective layer is about 120nm.

[0038] This kind with SiO 2 The deposition and stripping potential and impedance test results of the lithium sheet of the protective layer are listed in Table 1. The test results when it is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com