Dynamic amplifying optical film of flat Fresnel lens array

A technology of Fresnel lens and optical film, applied in optics, lens, magnifying glass, etc., can solve the problems of disappearing magnification effect of dynamic optical film, damage of safety film, inability to print ink directly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

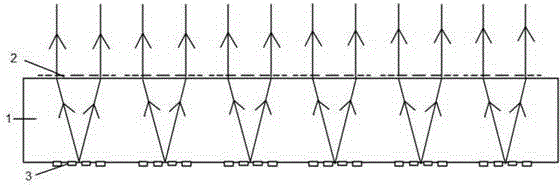

[0055] ginseng figure 1 Shown is a schematic structural view of a plane Fresnel lens array dynamic magnification optical film in Embodiment 1 of the present invention, including a substrate layer 1, a Fresnel lens array layer 2 and a micrographic layer 3, and a Fresnel lens array layer 2 and The micropattern layer 3 is respectively located on the upper surface and the lower surface of the substrate layer 1 .

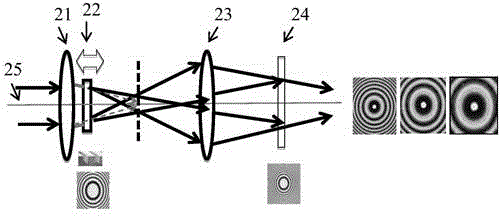

[0056] With reference to the photolithography equipment and photolithography method recorded in the Chinese patent application whose application number is CN201310166341.1, such as figure 2 As shown, the Fresnel lens array layer can be prepared by the above-mentioned interference lithography, the Fresnel lens array layer is composed of several Fresnel lenses arranged in an array, and the Fresnel lens includes the first Fourier transform arranged in sequence along the optical axis 25 A lens 21, a Fresnel phase element 22, a second Fourier transform lens 23, an output su...

Embodiment 2

[0063] ginseng Figure 4 Shown is the schematic structural diagram of the plane Fresnel lens array dynamic amplification optical film in the second embodiment of the present invention. Compared with the first embodiment, in this embodiment, a high refractive index film is evaporated on the outside of the Fresnel lens array layer 2. The dielectric layer 4 is the same as that of the first embodiment, and will not be repeated here. In this embodiment, various patterns can be directly printed on the high refractive index medium layer 4, and the high refractive index medium layer 4 can also be used as a protective layer for the Fresnel lens array layer.

[0064] The nano-Fresnel lens belongs to the planar process, and a high-refractive-index medium, such as ZnS medium, is vapor-deposited on the Fresnel lens array layer, and its refractive index is about 2.0. According to the grating equation, if the incident wavelength is 550nm and the incident wavelength is vertical, the edge per...

Embodiment 3

[0066] Different color inks are applied to different areas of the Fresnel lens array layer 2, which can be combined with the color of the ink filled in the micrographic layer 3. On the upper and lower surfaces of the integrated imaging optical film, the color of the micro graphics is different from the color printed on the surface, which can form a dynamic graphic effect of two different color combinations.

[0067] ginseng Figure 5 As shown, in the present embodiment, the Fresnel lens array layer 2 is divided into a first area 201 and a second area 202, and different inks are printed on the first area 201 and the second area 202, such as painting blue transparent ink on the first area 201 Ink, red transparent ink is printed on the second area 202 . The Fresnel lens itself has a dispersion effect, and when it converges light of different wavelengths, the corresponding focal length is different. Then the focal length of the required Fresnel lens can be adopted according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com