Tobacco cellulose content determination method

A technology of tobacco cellulose and measurement method, which is applied in the direction of analysis by nuclear magnetic resonance, etc., can solve the problems of unsatisfactory correlation coefficient of standard working curve, systematic error of measurement results, and failure to find, etc., to achieve accurate and reliable measurement results, and eliminate impurity peaks The effect of interference and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

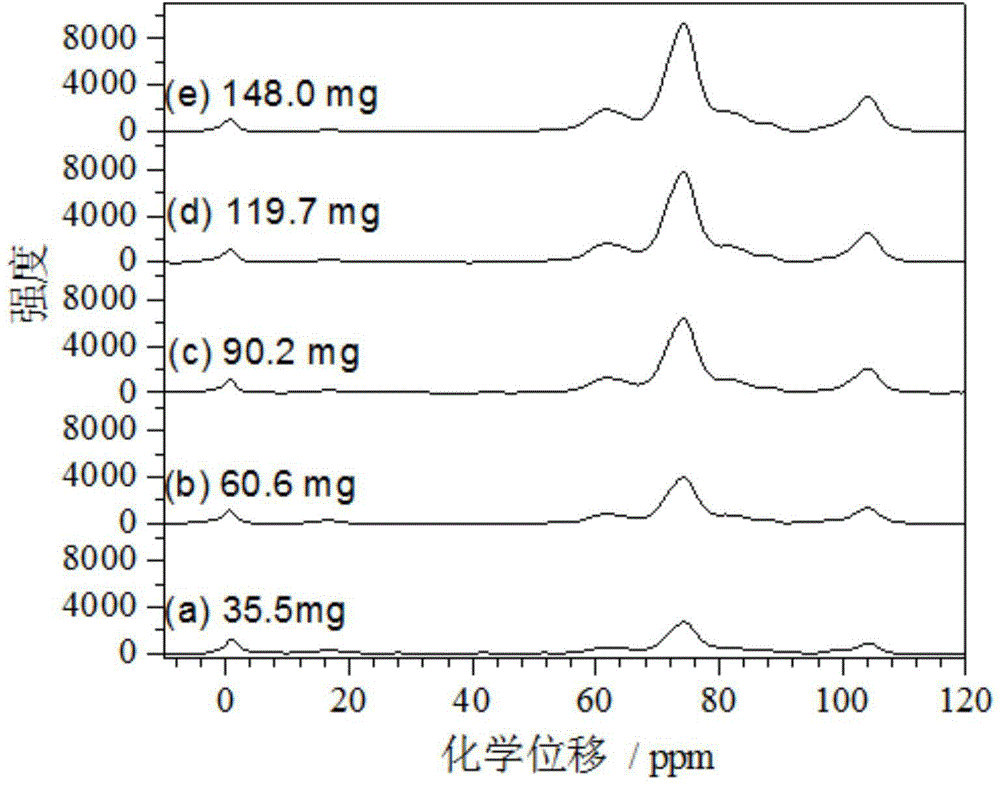

[0030] First, accurately weigh 35.5mg, 60.6mg, 90.2mg, 119.7mg and 148.0mg of cellulose standard sample powder with a cellulose content of 90.47%, respectively, and place them in a sample tube with a silica gel tube as the internal standard. 13 cross-polarization magic angle rotating nuclear magnetic resonance spectrometer is tested to obtain the spectrograms of each sample, such as figure 1 shown.

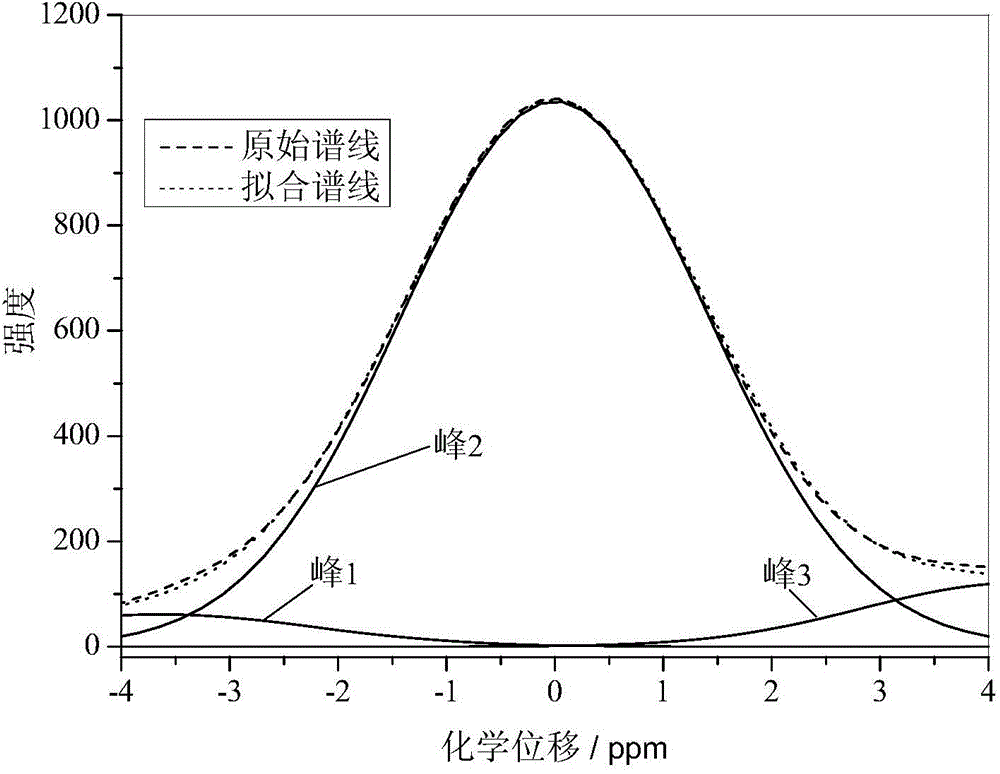

[0031] then, yes figure 1 The cellulose peak at 105.5ppm and the internal standard peak at 0ppm in the spectrograms of five cellulose standard samples in the sample were used for baseline correction, second derivatives, Fourier deconvolution and curves using PeakFit v4.12 software Fitting processing, the quantitative peak area of cellulose and the quantitative peak area of the internal standard in the same spectrum were obtained.

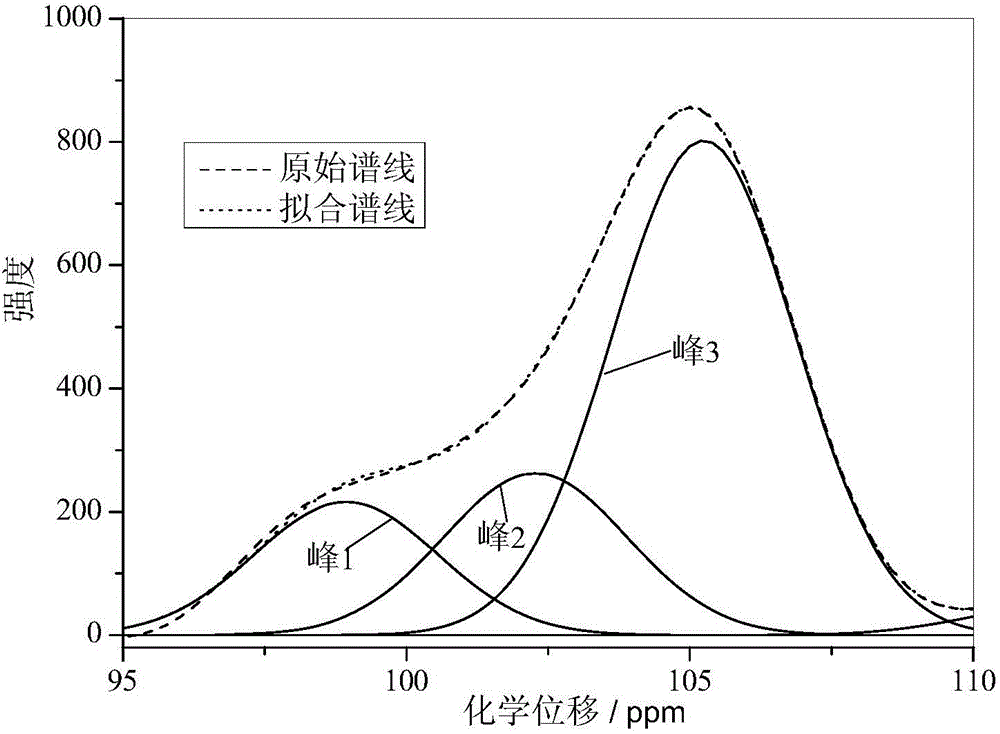

[0032] figure 2 Among the 5 cellulose standard samples, the original curve, fitting curve and sub-peaks obtained by processing the cellulose pe...

Embodiment 2

[0037] Take by weighing 0.2g (accurately weighing to 0.0002g) tobacco sample powder to be tested (Yunyan 87X2F), parallel 5 parts (sample number 1-5), repeat the test and data processing of Example 1, obtain the average value of 5 repeated tests , standard deviation and relative standard deviation, the results are shown in Table 1.

[0038] Table 15 mean, standard deviation and relative standard deviation of repeated tests

[0039] Sample serial number

[0040] 4

Embodiment 3

[0042] Take 8 kinds of tobacco samples (sample number 1#-8#), divide each sample into two parts, one part is according to the tobacco industry standard "Tobacco and Tobacco Products Cellulose, Hemicellulose, Lignin Determination Method" method Tested, the other was tested according to the method steps described in Example 1, and the results are shown in Table 2.

[0043] Table 2 This method compares the determination results of cellulose in tobacco samples with the determination results of standard methods

[0044]

[0045] Therefore, the method for measuring tobacco cellulose content provided by the present invention is not only simple, fast, convenient, time-saving and labor-saving, but also accurate and reliable, and provides an effective technology for the tobacco industry to measure tobacco cellulose content in batches. ways and means.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com