Crane hoisting mechanism brake balance compensation device and brake composed thereof

A lifting mechanism and balance compensation technology, applied in the direction of brake types, drum brakes, hoisting devices, etc., can solve the problems of aggravating the wear of brake pads and brake wheels 25, inconsistent relative positions, and affecting braking effects, etc. , to achieve the effect of reducing maintenance frequency, improving work reliability, and avoiding untimely adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

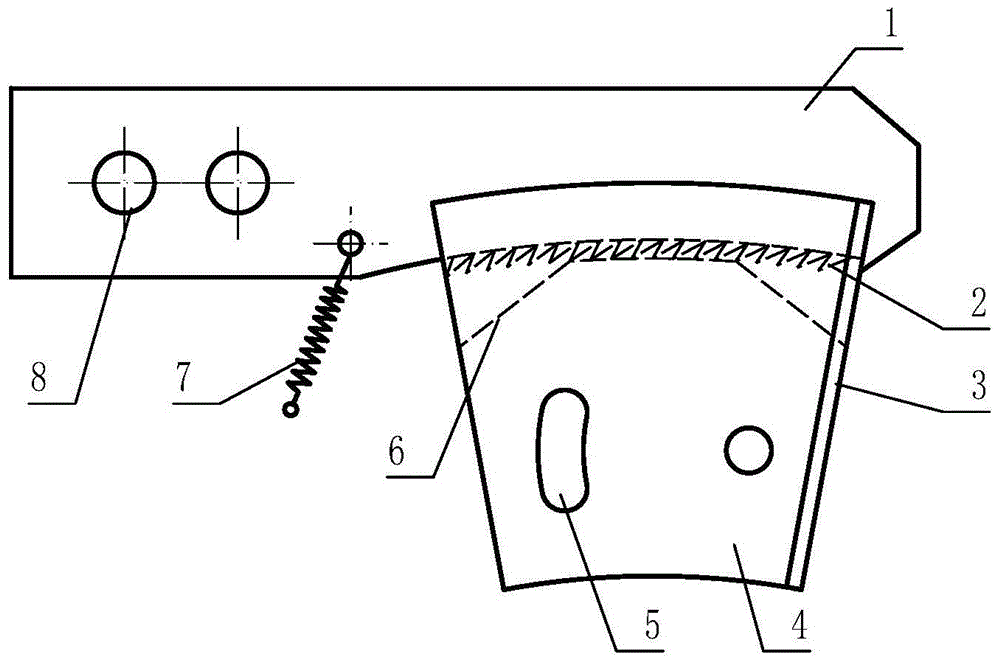

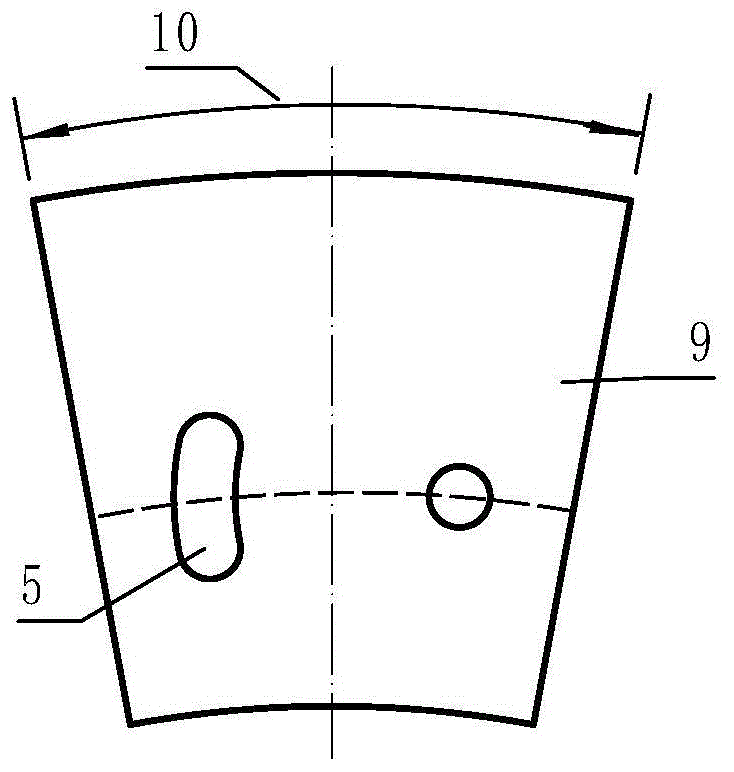

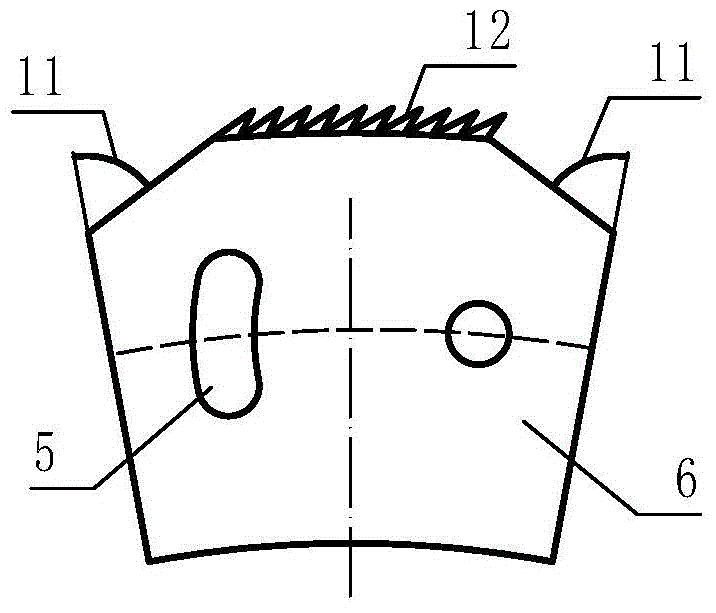

[0045] refer to figure 1 — Figure 6 , a brake balance compensation device for a crane hoisting mechanism, is characterized in that it mainly includes an arc rack 1, a sector ring tooth 6, a sector ring tooth splint 9, a sector ring tooth outer splint 4, and a tension spring 7, and the arc tooth The bar 1 is provided with sawtooth I2, the end of the curved rack 1 is provided with a hinge shaft hole 8, and the fan ring tooth 6 is provided with a sawtooth meshing with the serrated I2 provided on the curved rack 1 II12, the arc-shaped rack 1 and the sector ring teeth 6 are engaged with each other, the sector ring teeth 6 are sandwiched between the sector ring tooth splint 9 and the sector ring tooth outer splint 4, the sector ring teeth 6, The fan ring tooth splint 9 and the fan ring tooth outer splint 4 are provided with installation holes I5, the fan ring teeth 6, the fan ring tooth splint 9, and the fan ring tooth outer splint 4 are fixedly connected through the installation...

Embodiment 2

[0048] Compared with Embodiment 1, the difference of this embodiment is that: the fan ring teeth 6, the fan ring tooth splint 9, and the fan ring tooth outer splint 4 are all fan-shaped surfaces, and the angle A10 formed by the fan-shaped surfaces is 21 degrees.

Embodiment 3

[0050] Compared with Embodiment 2, the difference of this embodiment is that: the fan-shaped face of the sector ring tooth 6 is symmetrically provided with two cut corners, and the angle B11 formed by the cut corners is 63 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com