Coupling

A coupling and joint surface technology, applied in the field of mechanical parts, can solve problems such as vehicle inoperability, damage to the power box, damage to the input shaft of the power box, etc., achieve good buffering and absorption effects, avoid direct shutdown, and prevent falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following description, many specific details are explained in order to fully understand this application. However, this application can be implemented in many other ways different from those described herein, and those skilled in the art can make similar promotion without violating the connotation of this application. Therefore, this application is not limited by the specific implementation disclosed below.

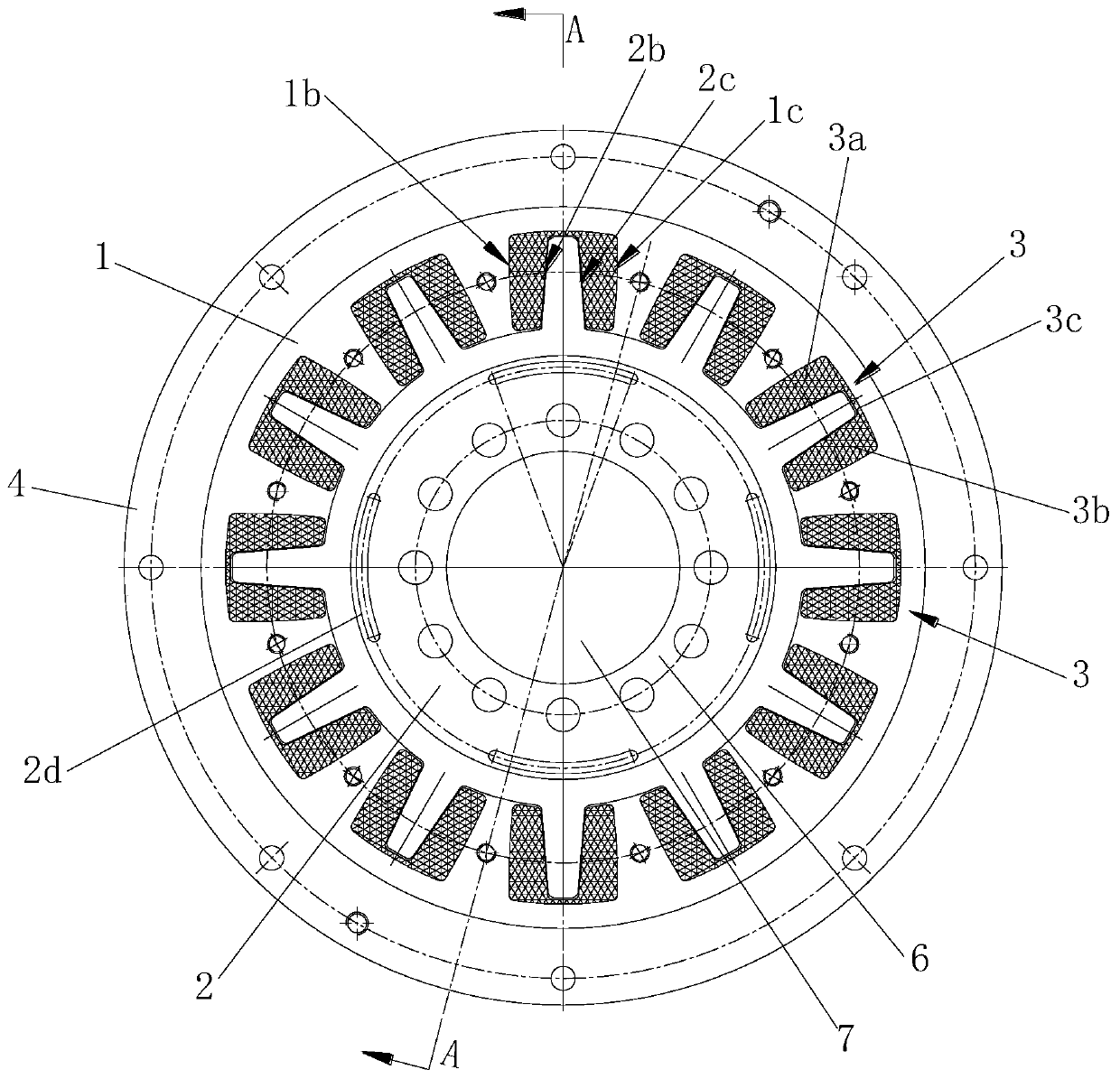

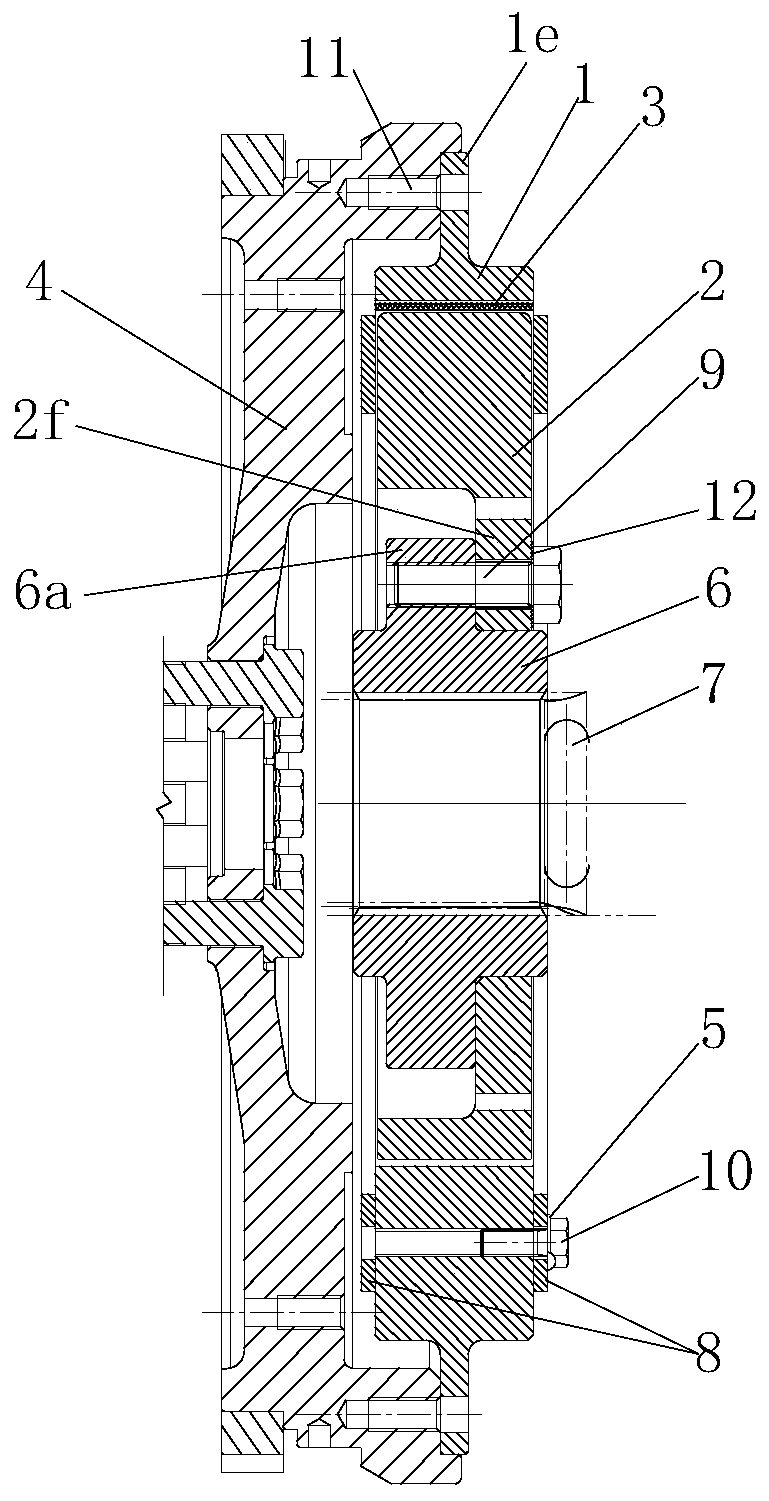

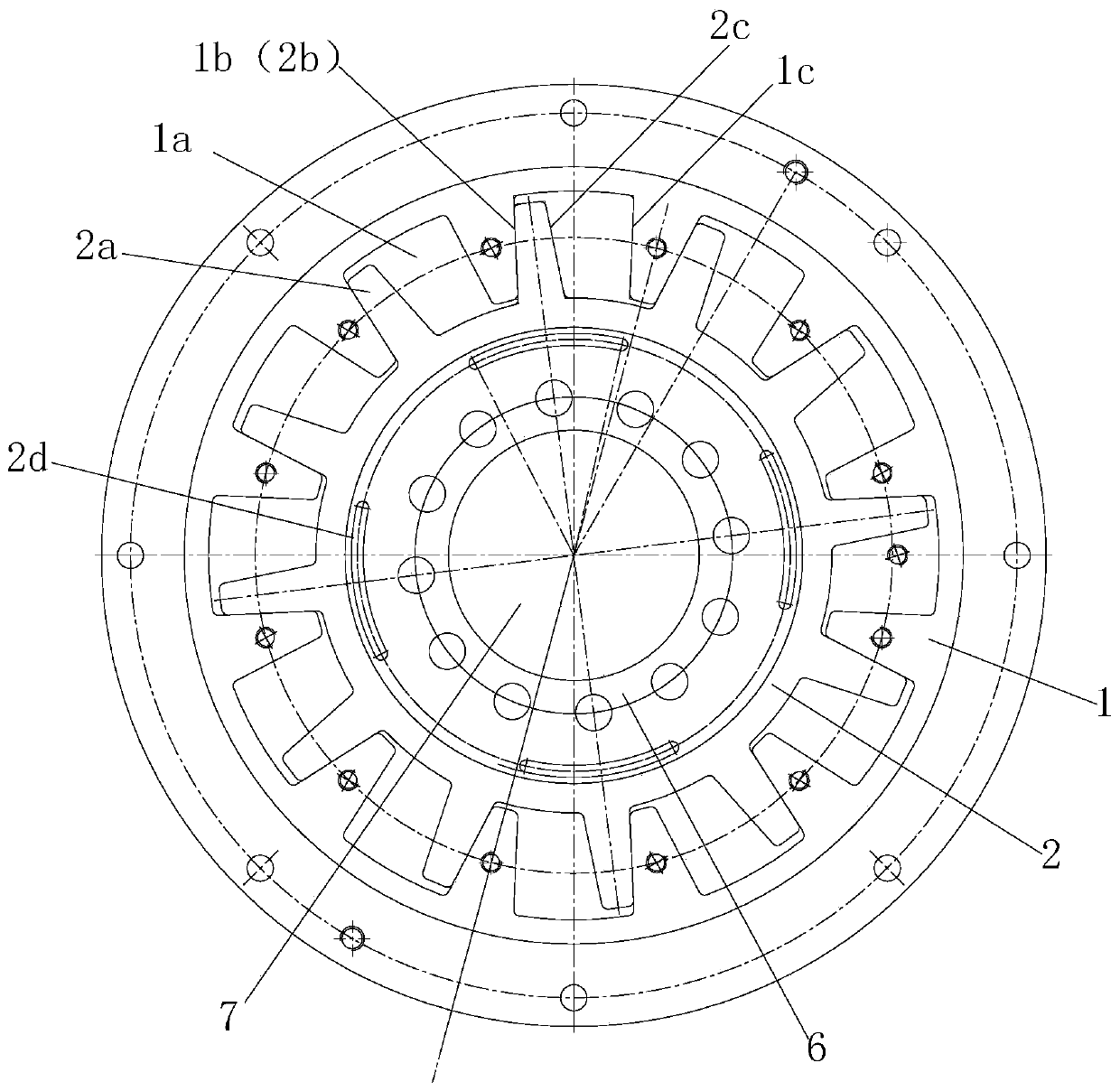

[0043] Such as figure 1 with figure 2 The coupling shown includes an external gear plate 1 for connecting with an internal combustion engine flywheel 4 to transmit torque and speed, and a power input for transmitting the torque and speed output by the external gear plate 1 to a power box. The inner toothed disk of the shaft 7, the vibration damping body 3 for absorbing the vibration of the flywheel 4 of the internal combustion engine, the damping body 3 is installed in the tooth hole 1a of the outer toothed disk 1 and the tooth 2a of the inner toothed disk 2 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com