Method and system for diagnosing fault of rotating speed sensor of supercharger based on real ship data

A speed sensor and fault diagnosis technology, which is applied in the directions of instruments, machines/engines, speed/acceleration/impact measurement, etc., can solve the problems of low accuracy and efficiency, and achieve the effect of improving state ability and host management ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

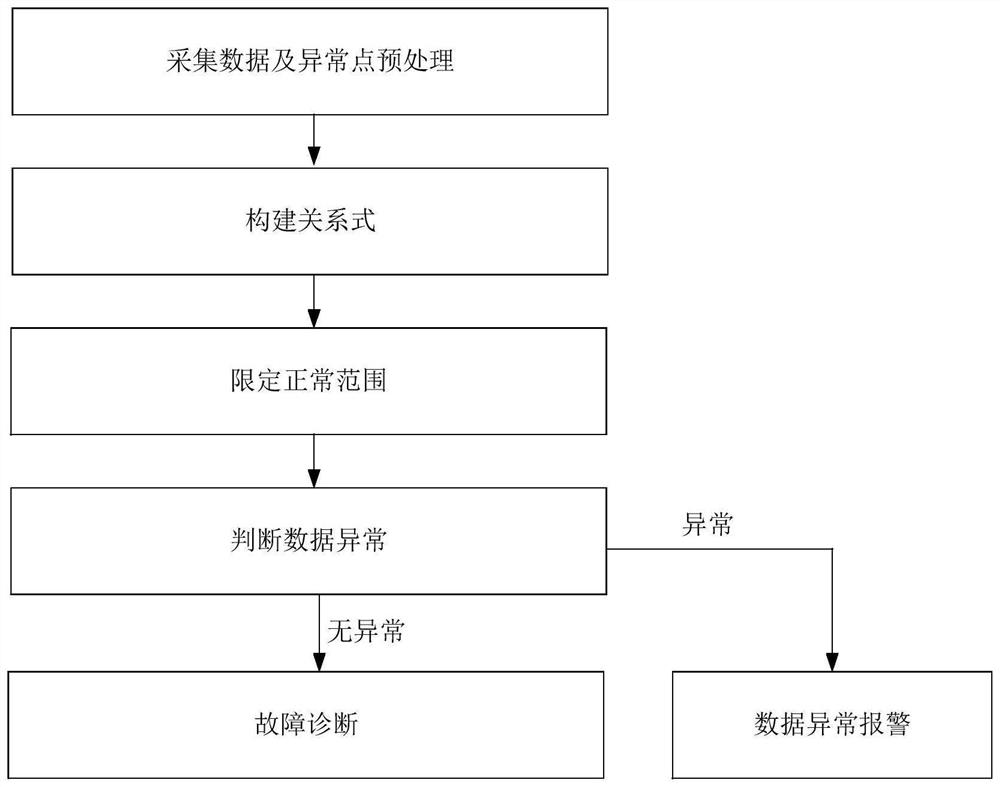

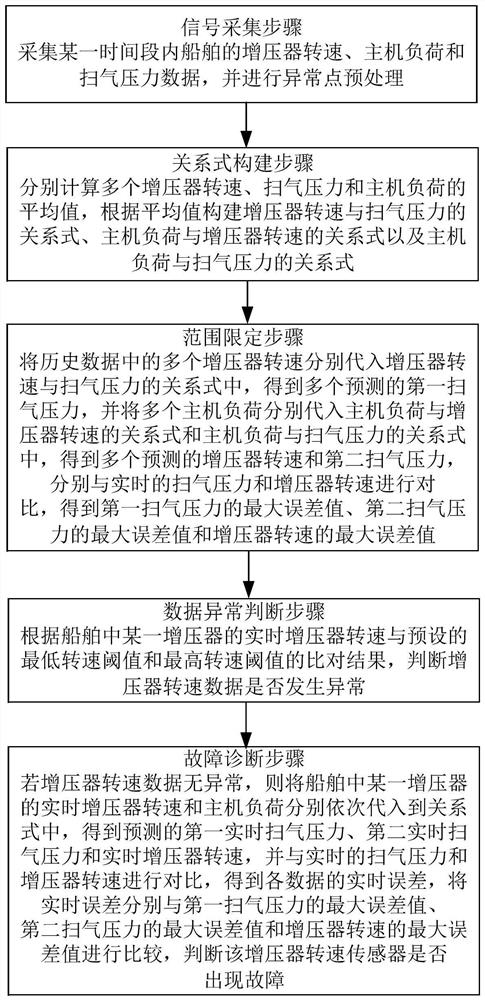

Method used

Image

Examples

Embodiment 1

[0049] For the target ship, one main engine has two superchargers, and one year of historical data is entered. The historical data includes the acquisition value of the rotational speed of the two superchargers, the acquisition value of the main engine load, and the acquisition value of the scavenging pressure. After signal processing, two superchargers are obtained. The relational expressions f1(x) and f2(x) between the speed of the compressor and the scavenging pressure, the relational expressions g1(x) and g2(x) between the load of the main engine and the rotational speed of the two superchargers, the relational expression of the load of the main engine and the scavenging pressure h (x);

[0050] Substitute the historical data into the relational formula for calculation, and obtain the maximum error values L1, L2, K1, K2, M of the two superchargers under the relational formula;

[0051] According to the supercharger speed value collected in real time, judge whether the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com