Casing gas containing hole impregnated diamond bit for geological exploration and manufacturing process

A diamond-impregnated, geological exploration technology, applied to drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problems of low drilling efficiency, no footage, slow drilling speed, etc., to improve the drilling speed and drilling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

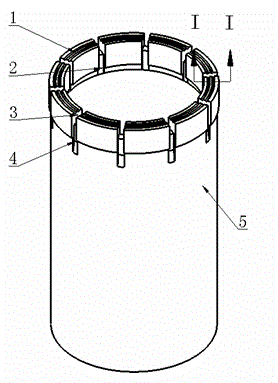

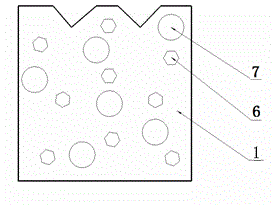

[0024] Referring to the accompanying drawings, the matrix-containing diamond drill bit impregnated with pores for geological exploration in this embodiment includes a steel body 5 and a matrix 1, the matrix 1 is located on the steel body 5, and an inner water tank is provided on the steel body 5 2. Nozzle 3, outer water tank 4, diamond 6 and air holes 7 are arranged in the carcass 1.

[0025] In this embodiment, the pores are spherical in shape with a diameter of 0.3-0.8 mm, and are evenly distributed in the working layer of the carcass. Among them, the total volume of pores accounts for 12.3% of the total volume of the carcass working layer.

[0026] Take the 8mm working layer carcass of the 75 / 49 rope drill as an example.

[0027] The manufacturing process includes the following steps:

[0028] (1) Weigh NaHCO 3 1.6g, glycerol 0.9g, the NaHCO 3 Add glycerin and stir evenly;

[0029] (2) Add 96.3g of matrix formula powder and 10.7g of diamond (GE960, particle size 30-40...

Embodiment 2

[0033] The carcass impregnated diamond drill bit with pores in this embodiment includes a steel body 5 and a carcass 1, the carcass 1 is located on the steel body 5, and the steel body 5 is provided with an inner water tank 2 and a nozzle 3 , The outer water tank 4, the carcass 1 is provided with diamonds 6 and air holes 7.

[0034] In this embodiment, the pores are spherical in shape with a diameter of 0.6-1.0 mm, and are evenly distributed in the working layer of the carcass. Among them, the total volume of pores accounts for 23.5% of the total volume of the carcass working layer.

[0035] The manufacturing process includes the following steps:

[0036] (1) Weigh (NH 4 ) 2 SO 4 1.1g, glycerol 0.4g, the weighed (NH 4 ) 2 SO 4 Add glycerin and stir evenly;

[0037] (2) Add 96.3g of matrix formula powder and 10.7g of diamond (GE960, particle size 30-40 mesh), among which, the matrix formula powder is: by mass ratio, 663 bronze powder: iron powder: tin powder: Nickel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com