Structural steel keel corner connecting stamping part and corner connecting structure

A technology of corner connection and stamping parts, applied in building components, building structures, walls, etc., can solve the problem of uneven processing quality of angle steel processing manufacturers, inability to strictly implement batch processing quality control, and weak strength and overall stability. and other problems, to achieve the effect of facilitating quality control, improving local stability, and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings, but it is not intended to limit the implementation scope of the present invention.

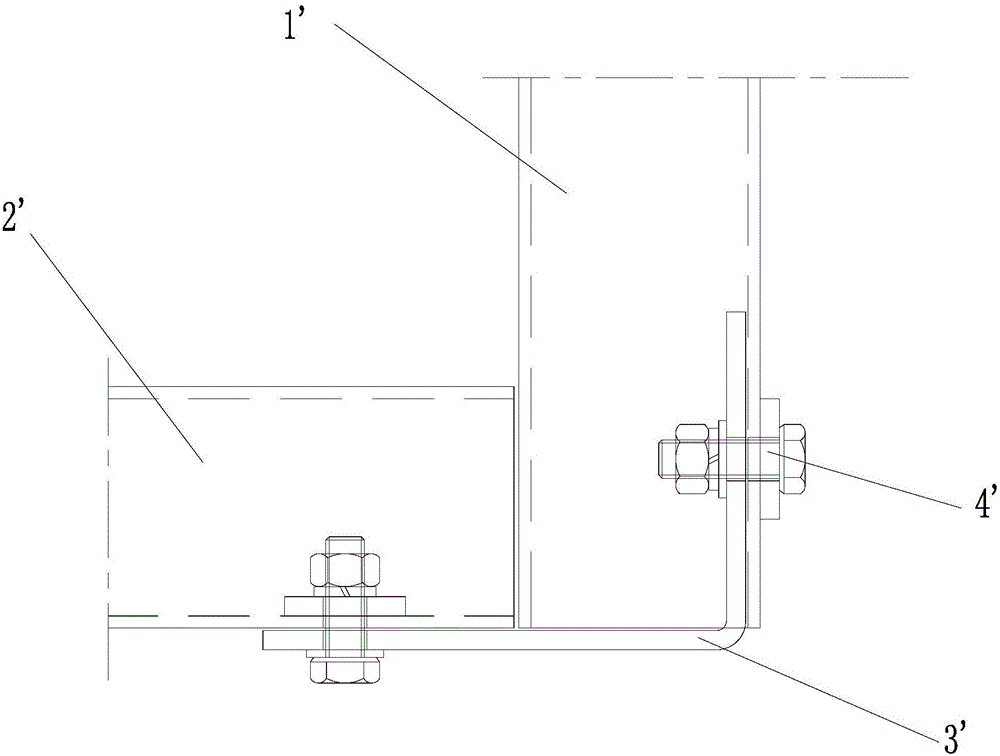

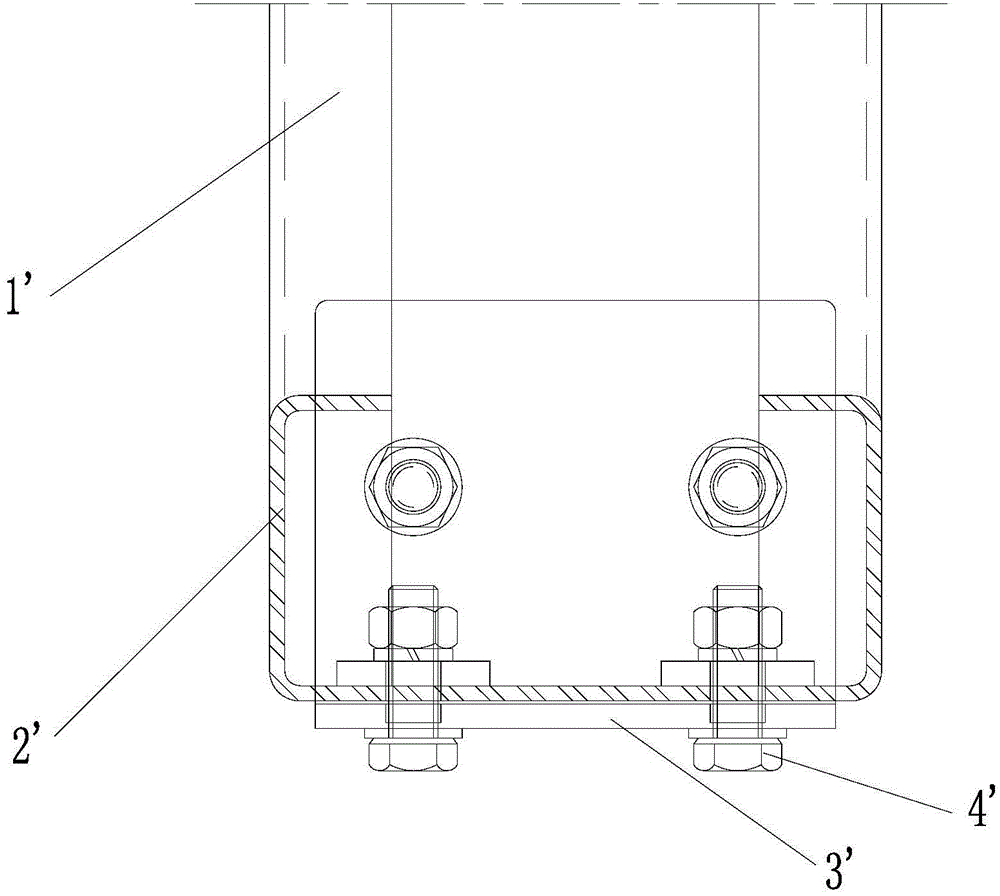

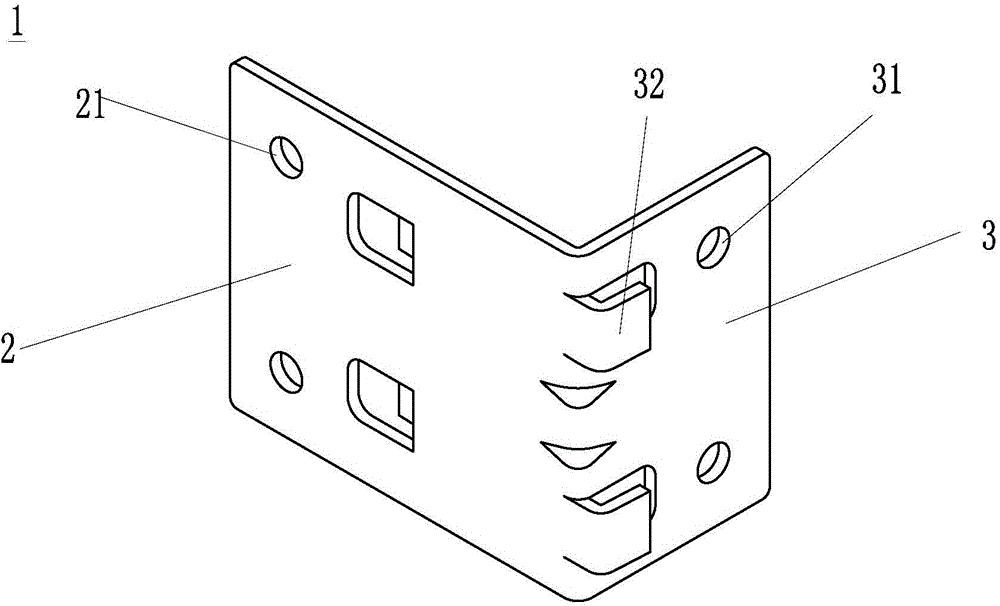

[0019] Such as Figure 3-Figure 4 As shown, the present invention provides a corner connection stamping of section steel keel, which includes an L-shaped body 1, which is stamped from Q345B steel plate. control. The body 1 includes a first surface 2 and a second surface 3 vertically connected to each other. The outer ends of the first surface 2 and the second surface 3 are provided with fixing holes 21, 31 for fixing with the corner keel of the curtain wall by bolts. The inner side of the first surface 2 is provided with one or more vertically arranged L-shaped first clamping plates 22, and the second surface 3 is provided with one or more vertical clamping plates 22 on the outside of the joint with the first surface 2. Arranged L-shaped second clamping boards 32 . Openings of the first clamping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com