Masonry structure and method for enhancing collapse resistance and integrity under strong earthquake

A kind of masonry structure and integral technology, applied in the direction of building components, building structure, building material processing, etc., can solve the problems of limited ability to resist horizontal loads, low rigidity of weak frame structures, and small effect of geometric shapes, etc., to achieve The effect of enhancing the ability to resist horizontal loads, maintaining geometric invariance, and improving the ability to resist horizontal loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

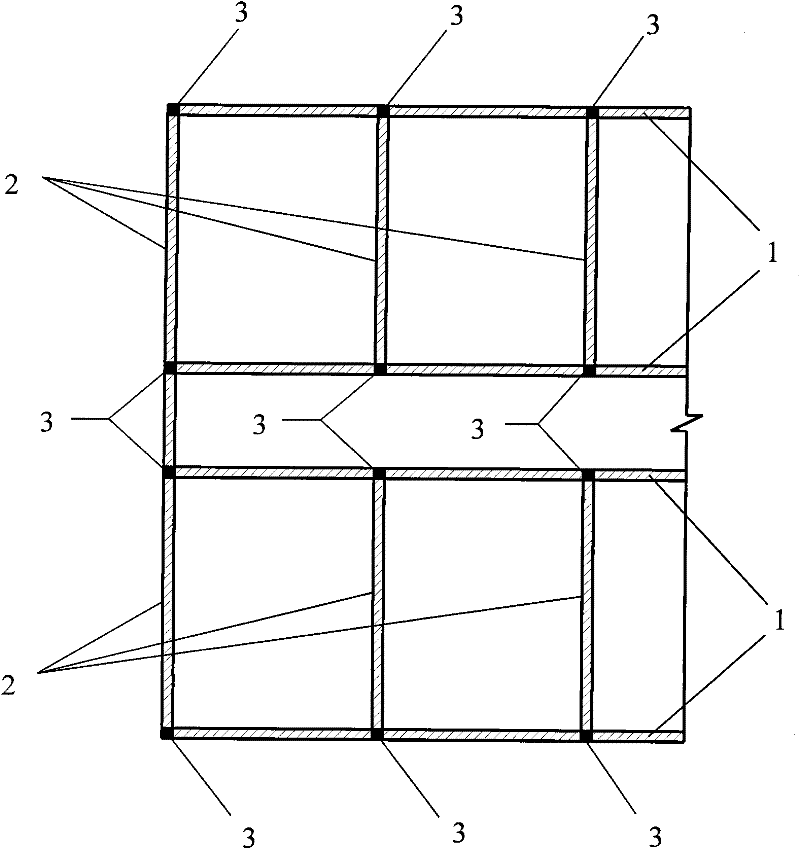

[0036] figure 1 It is a local layout plan of the existing masonry structure. Structural columns 3 are arranged at the junction of the longitudinal wall 1 and the transverse wall 2, and are connected up and down. Since the lengths of the longitudinal wall 1 and the transverse wall 2 are different, and different seismic fortification intensities of structures require different intervals of the structural columns 3 , the spacing of the structural columns 3 is not fixed. Such as figure 1 As shown, the spacing of the structural columns 3 arranged in the longitudinal wall 1 is the same as the story height, and the spacing of the structural columns 3 arranged in the transverse wall 2 is larger than the story height.

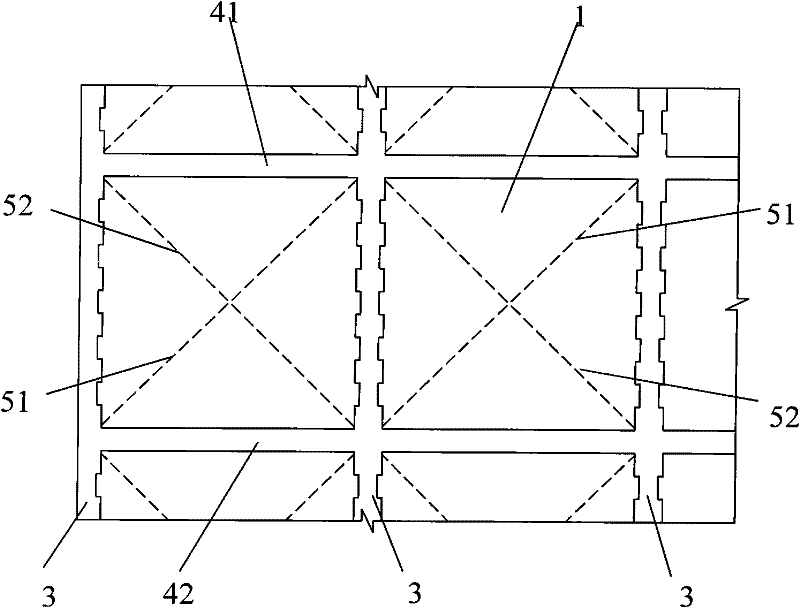

[0037] figure 2 It is a schematic diagram of the elevation of the structure after setting a group of reinforcing steel bars between two adjacent structural columns according to the present invention. A ring beam 4 is arranged at the joint between the floor and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com