Construction method for underground diaphragm wall penetrating through super-thick silt layer

An underground diaphragm wall and construction method technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve problems such as difficulty in controlling the quality of grooves, increased engineering costs, and long construction periods, so as to improve construction efficiency and speed up construction Progress and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

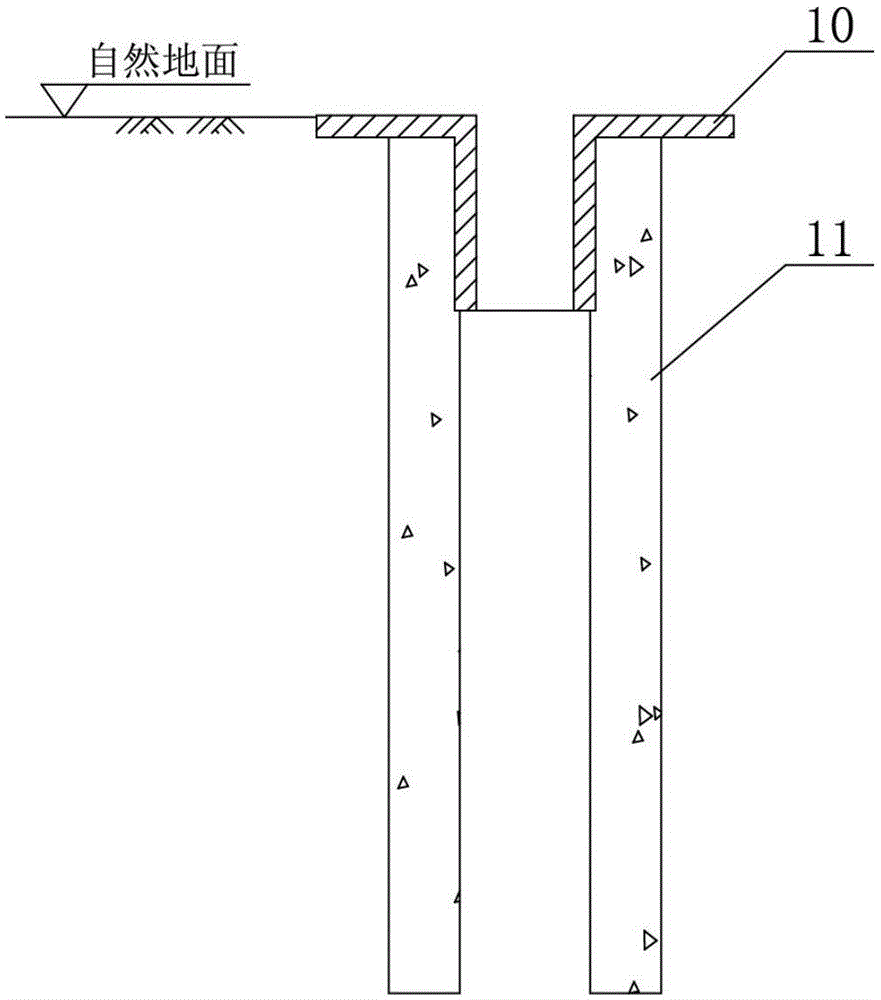

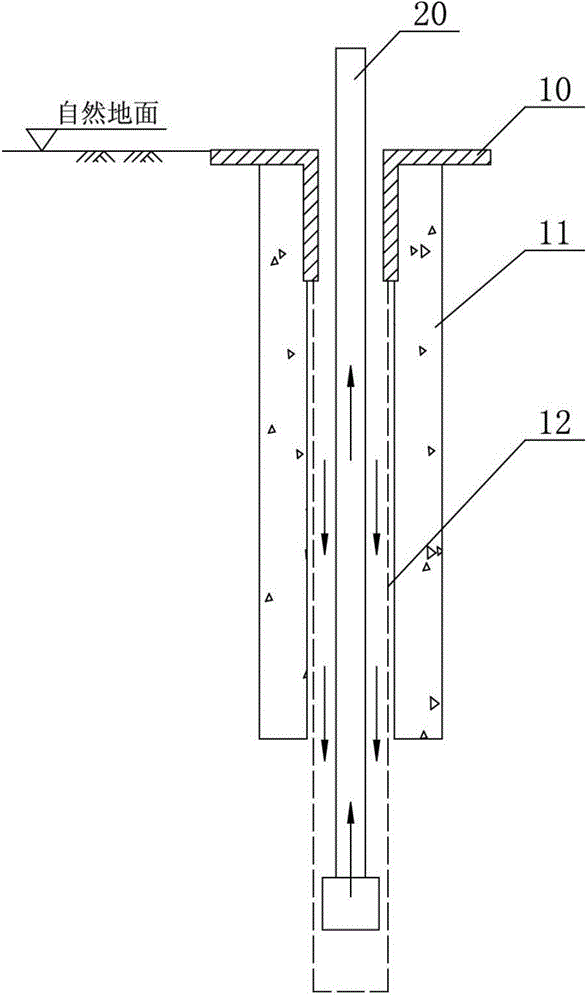

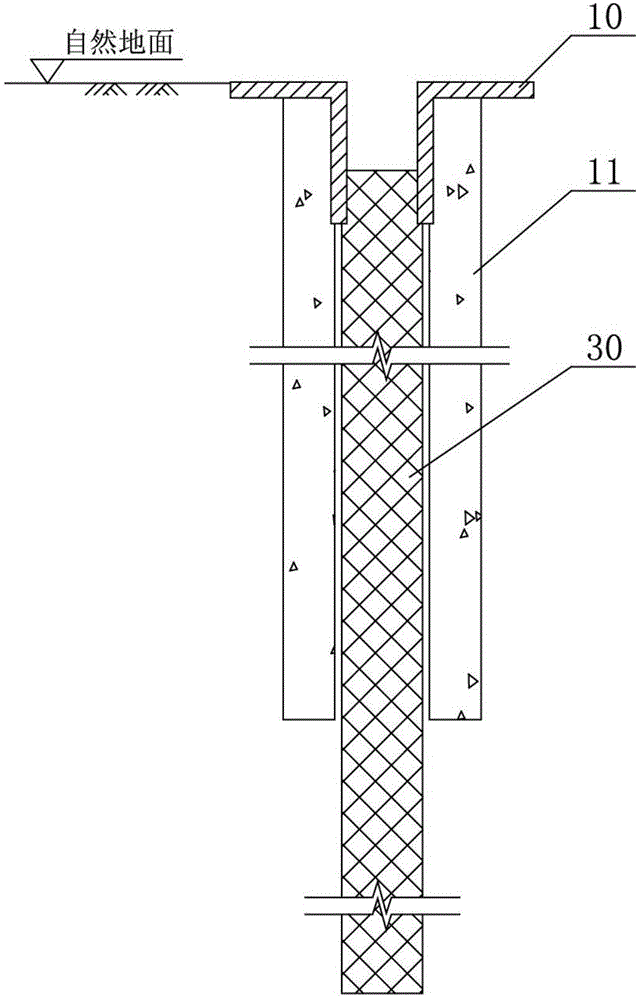

[0026] The construction method of the underground diaphragm wall penetrating through the ultra-thick silt layer proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. The technical content and features of the present invention will be described in detail below by referring to the illustrated embodiments in conjunction with the accompanying drawings. It should be further noted that all the drawings are in very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0027] The engineering site of this embodiment requires the construction depth of the underground diaphragm wall to be 60 meters. Before entering the rock, it is a deep sandy soil layer with a thickness of 55 me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com