Homogenization heat treatment process for lowering anisotropy of wide rolled aluminum plate

A homogeneous heat treatment and anisotropic technology, applied in the field of aluminum alloy processing, to achieve the effect of improving plasticity, reducing solid solution strengthening, and increasing precipitation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: A homogenization heat treatment process for reducing the anisotropy of wide-width rolled aluminum plates, comprising the steps of:

[0019] The ingot of 5052 alloy added with 0.3 wt% Er was used, and then the alloy was subjected to two-stage homogenization heat treatment.

[0020] First, carry out homogenization and heat preservation at 560°C for 30 h (first-level homogenization);

[0021] Subsequently, it was cooled to 300 °C and kept for 10 h (secondary homogenization), and then it was taken out of the furnace and air-cooled to room temperature.

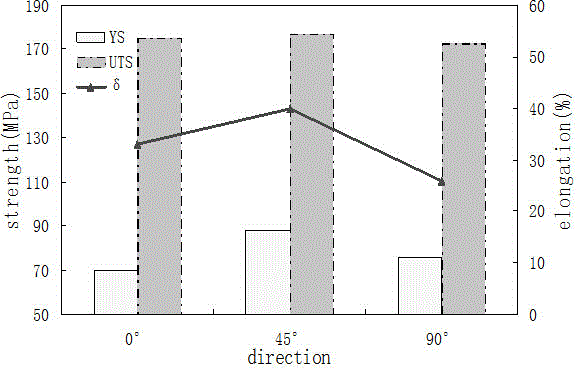

[0022] The ingot that has undergone the above-mentioned two-stage homogenization treatment is hot-rolled at a rolling temperature of 470°C. Before rolling, the rolled billet is preheated at 470°C for 1 h, and the total rolling reduction is 73%. The obtained plate was tested for tensile mechanical properties at room temperature along the rolling direction, vertical rolling direction and 45° direction, and the te...

Embodiment 2

[0023] Example 2: A homogenization heat treatment process for reducing the anisotropy of wide-width rolled aluminum plates, comprising the steps of:

[0024] Add 0.2 wt% (or 0.3 wt% or 0.4wt%) rare earth element Er to the 5052 alloy, and then perform three-stage homogenization heat treatment:

[0025] First, the 5052 alloy ingot added with rare earth element Er was subjected to homogenization and heat preservation at 560 °C for 30 h, that is, first-level homogenization;

[0026] Subsequently, cool to 150°C and hold for 10 h, that is, secondary homogenization;

[0027] Then, the temperature was raised to 300°C, and the temperature was continued for 10 h, that is, three-stage homogenization;

[0028] Finally, take out of the oven and air cool to room temperature.

[0029] The ingot that has undergone the above-mentioned three-stage homogenization treatment is hot-rolled at a rolling temperature of 470°C. Before rolling, the rolled billet is preheated at 470°C for 1 h, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com