a nanotio 2 Preparation method of modified composite hydrogel

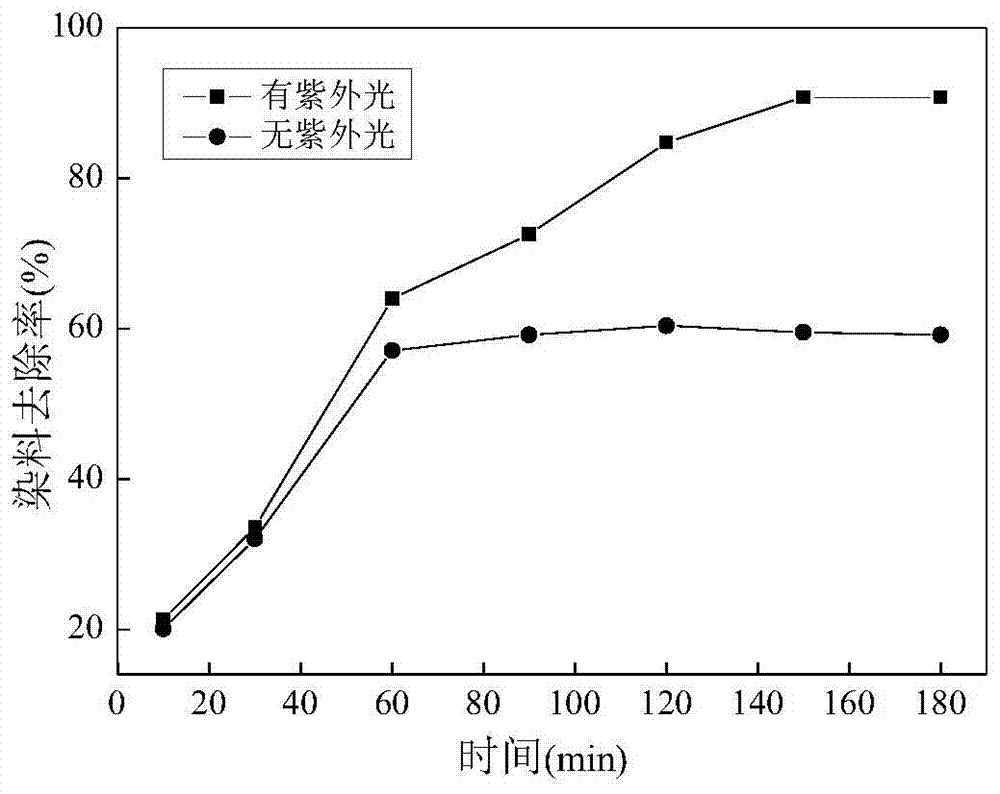

A composite hydrogel and nanotechnology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of low adsorption efficiency and poor adsorption effect, To achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of nanometer TiO of the present invention 2 The preparation method of modified composite hydrogel specifically comprises the following steps:

[0026] Step 1: dissolving chitosan in an acetic acid solution with a mass concentration of 1% to 2%, the mass ratio of chitosan to acetic acid solution being 1:50 to 100, and magnetic stirring for 12 to 24 hours to obtain a chitosan solution;

[0027] Step 2: N’N-methylenebisacrylamide (BIS), nano-TiO 2 , N-isopropylacrylamide (NIPAAm) into the three-necked flask, N'N-methylenebisacrylamide (BIS), nano-TiO 2 , The mass ratio of N-isopropylacrylamide (NIPAAm) to chitosan is 2.5~3.5:0.23~0.36:2.3~3.6:1, nano-TiO 2 Anatase type is preferred, the particle size is preferably 10-30nm, mixed with the chitosan solution obtained in step 1, and ultrasonically dispersed for 10-20 minutes to obtain a mixed solution;

[0028] Step 3: Add initiator and tetramethylethylenediamine to the mixed solution obtained in step 2 under the pro...

Embodiment 1

[0032] Step 1: dissolving 1g of chitosan in 66g of acetic acid solution with a mass concentration of 1%, and magnetic stirring for 24 hours to obtain a chitosan solution;

[0033] Step 2: 2.8g N'N-methylenebisacrylamide (BIS), 0.3g anatase-type nano-TiO with an average particle size of 20nm 2 , 3g N-isopropylacrylamide (NIPAAm) was added in the three-necked flask, and mixed with the chitosan solution obtained in step 1, and ultrasonically dispersed for 10min to obtain a mixed solution;

[0034] Step 3: At room temperature and under the protection of nitrogen, add 0.08g ammonium persulfate and 0.03g tetramethylethylenediamine to the mixed solution obtained in step 2, stir and react for 1h, then freeze and react for 24h to obtain nano-TiO 2 Modified composite hydrogel crude product;

[0035] Step 4: the nano-TiO obtained in step 3 2 The crude product of the modified composite hydrogel was soaked in deionized water for 24 hours, and the water was changed once every 4 hours. 2 ...

Embodiment 2

[0037] Step 1: dissolving 1g of chitosan in 50g of acetic acid solution with a mass concentration of 2%, and magnetic stirring for 12 hours to obtain a chitosan solution;

[0038] Step 2: 2.5g N'N-methylenebisacrylamide (BIS), 0.36g nano-TiO with anatase average particle size of 10nm 2, 2.3g N-isopropylacrylamide (NIPAAm) was added in a three-necked flask, and mixed with the chitosan solution obtained in step 1, and ultrasonically dispersed for 15min to obtain a mixed solution;

[0039] Step 3: At room temperature and under the protection of nitrogen, add 0.12 g potassium persulfate and 0.05 g tetramethylethylenediamine to the mixed solution obtained in step 2, stir and react for 0.5 h, then freeze and react for 18 h to obtain nano-TiO 2 Modified composite hydrogel crude product;

[0040] Step 4: the nano-TiO obtained in step 3 2 The crude product of the modified composite hydrogel was soaked in deionized water for 24 hours, and the water was changed once every 3 hours. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com