Power-on and power-off control method for electric automobile

An electric vehicle and electric control technology, applied in electric vehicles, electrical devices, vehicle components, etc., can solve problems such as user trouble, overheating damage, pre-charging resistance impact, etc., to reduce maintenance costs, improve safety factor, and avoid damage. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below.

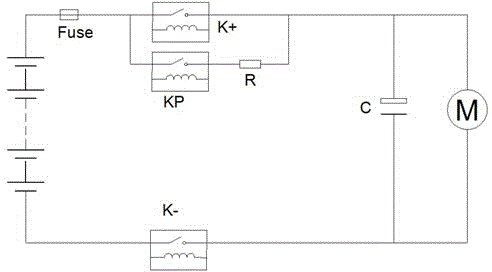

[0017] In the present invention, the strategy of combining hardware and software is used to protect the electric vehicle pre-charging resistor.

[0018] On the hardware, the temperature sensor is used to collect and detect the temperature of the pre-charging resistor, and the software monitors the temperature of the pre-charging resistor in real time during the pre-charging step of the power-on process. If the temperature exceeds the set value (generally, the set value is 120 degrees), that is Disconnect the pre-charging relay, stop power on, and protect the pre-charging resistor. At the same time, the total positive relay is also protected, and it is not allowed to close, so that the pre-charging operation can only be performed after the temperature of the pre-charging resistor drops and recovers.

[0019] At the same time, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com