Conveying mechanism of corrugated pipe cut-off machine

A technology of corrugated pipe cutting machine and conveying mechanism, which is applied in metal processing and other directions, and can solve the problems of low cutting efficiency, slipping, shaking of pipe fittings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

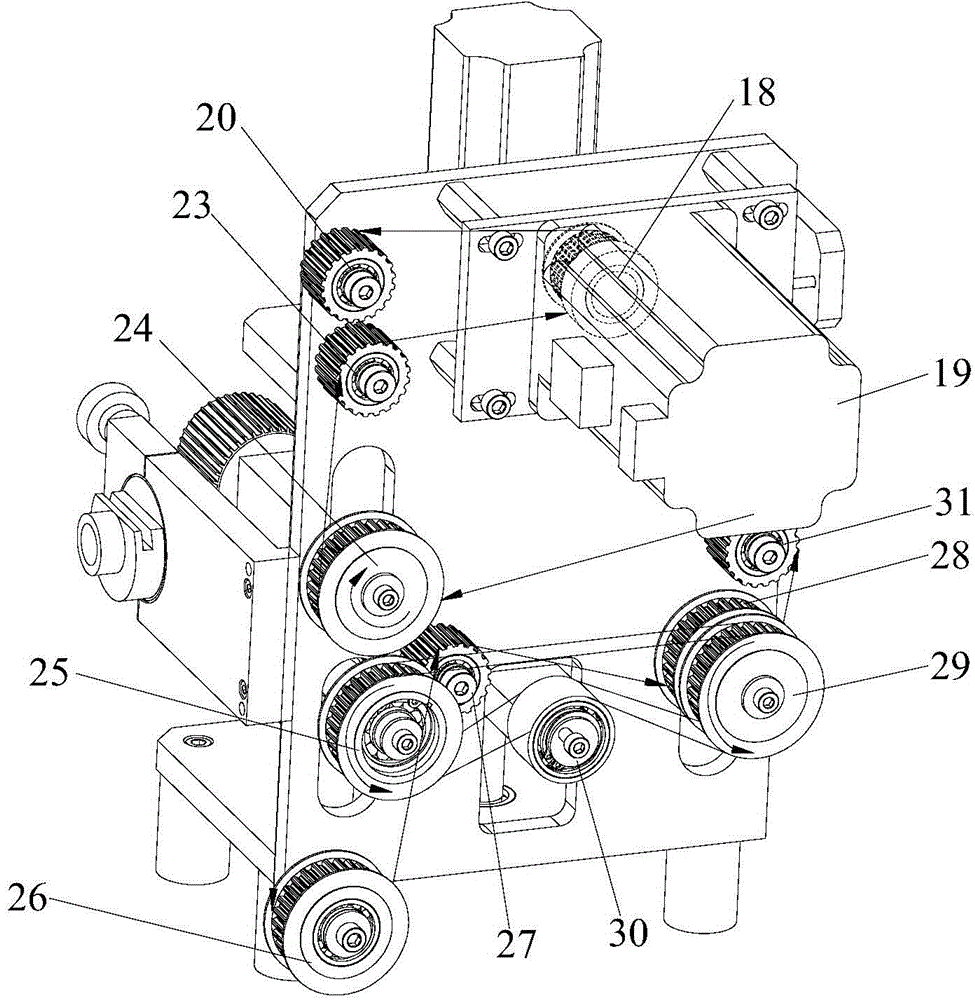

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0026] see figure 1 and figure 2 As shown, the conveying mechanism of a bellows cutting machine according to a preferred embodiment of the present invention includes a base 1, a first support 2 arranged on the base 1 for carrying parts, and the first support 2 It includes a vertically arranged bracket 21, a base 22 arranged at the bottom of the bracket 21 and extending toward the front end, the base 22 is fixed on the base 1, and the conveying mechanism also includes a first conveying wheel 3 and a second conveyor wheel 3 positioned above the base 22 and oppositely arranged up and down. Two conveying wheels 4, the outer circumferential surfaces of the first conveying wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com