Secondary bending mechanism for pipe fitting

A technology for secondary bending and pipe fittings, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of unstable bending shape, poor product specifications, and low production efficiency, and achieve good shape specifications, The effect of low scrap rate and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

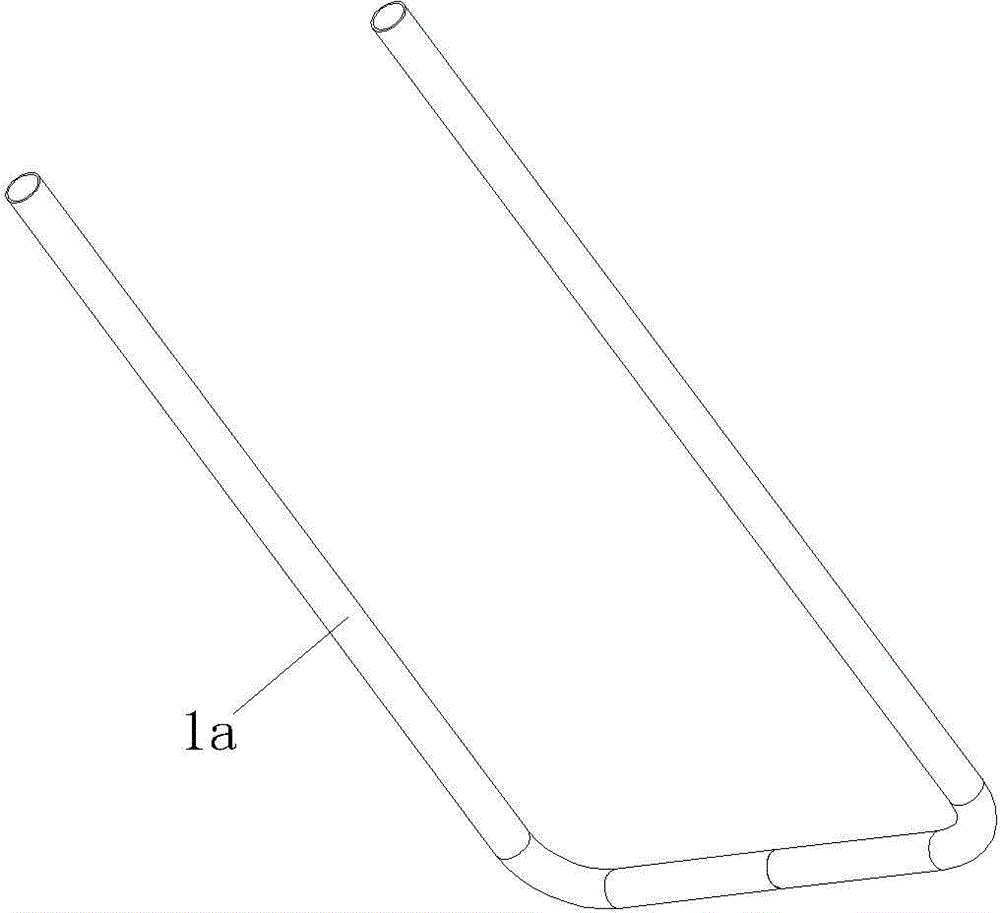

[0026] Figure 3 to Figure 7 As shown, a second bending mechanism for pipe fittings includes a workbench 1, on which a pipe support base 2, a primary bending support base 3, and a secondary bending support base 4 are sequentially provided, and the pipe support base 2, The upper surface of the primary bending support base 3 and the secondary bending support base 4 are respectively provided with a clamping press block 5, a primary bending press block 6 and a secondary bending press block 7;

[0027] The opposite end faces of the clamping pressure block 5 and the pipe fitting support seat 2 are provided with clamping arc-shaped grooves 51, 21 that are matched with the pipe fitting 1a. The primary bending pressure block 6 and the primary bending support seat 3 are provided on the corresponding end faces with the pipe fitting 1a. Matching with the primary be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com