Niobium-zirconium ore mineral separation method

A separation method, technology of niobium-zirconium ore, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of low recovery rate, low recovery rate of fine-grained tantalum-niobium ore, and low processing capacity, and achieve recovery rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

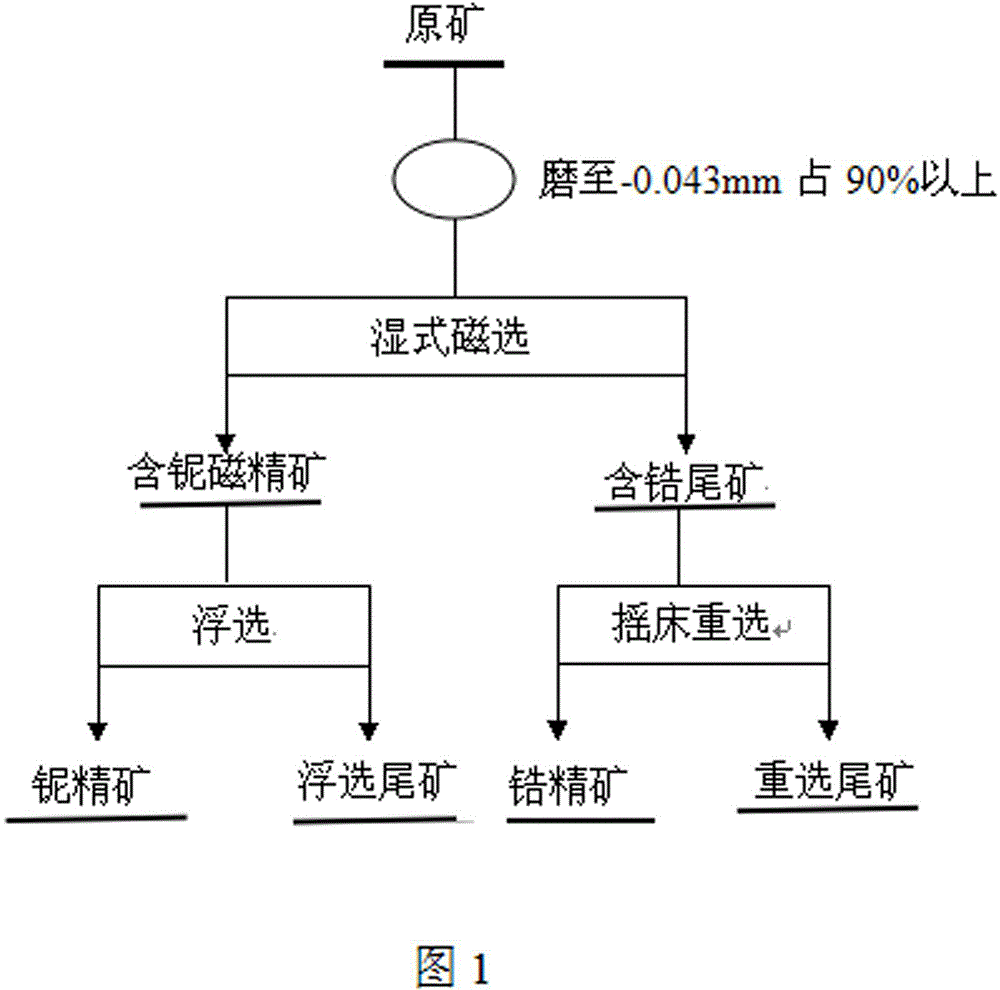

Method used

Image

Examples

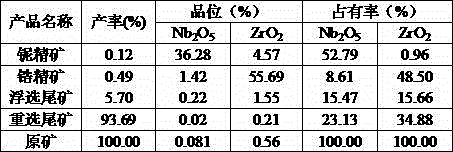

Embodiment 1

[0012] The raw ore of a niobium-zirconium ore in Shaanxi contains Nb 2 o 5 0.081%, ZrO 2 0.56%.

[0013] Grinding: crushing, grinding to -0.043mm accounts for 95%;

[0014] Wet magnetic separation: the magnetic field strength is 1000mT, the pulsation frequency is 200r / min, wet magnetic separation can separate niobium-containing magnetic minerals from zirconium-containing non-magnetic minerals, obtain niobium-containing magnetite concentrates and zirconium-containing tailings, and initially enrich niobium minerals ;

[0015] Flotation of niobium-containing magnetic concentrates: using a combination of water glass and hydroxamic acid, a process of primary roughing, secondary sweeping, and secondary beneficiation to obtain niobium concentrates by flotation of niobium-containing magnetic concentrates. Among them, the amount of rough water glass is 2000g / t, stirred for 5 minutes, the amount of hydroxamic acid is 600g / t, stirred for 3 minutes; the amount of sweeping monohydroxa...

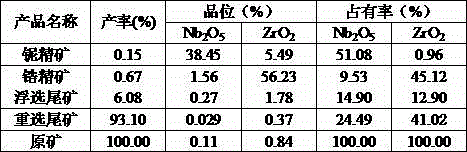

Embodiment 2

[0021] The original ore of a niobium-zirconium ore in Jiangxi contains Nb 2 o 5 0.11%, ZrO 2 0.84%.

[0022] Grinding: crushing, grinding to -0.043mm accounts for 98%;

[0023] Wet magnetic separation: the magnetic field strength is 1100mT, the pulsation frequency is 200r / min, wet strong magnetic separation can separate niobium-containing magnetic minerals from zirconium-containing non-magnetic minerals, and obtain niobium-containing magnetic concentrates and zirconium-containing tailings, making niobium minerals initially rich set;

[0024] Flotation of niobium-containing magnetic concentrates: using a combination of water glass and hydroxamic acid, a process of primary roughing, primary sweeping, and secondary beneficiation to obtain niobium concentrates by flotation of niobium-containing magnetic concentrates. Among them, the dosage of rough water glass is 1200g / t, stirred for 3 minutes, the dosage of hydroxamic acid is 400g / t, stirred for 3 minutes; the dosage of swee...

Embodiment 3

[0030] A niobium-zirconium ore in Inner Mongolia contains Nb 2 o 5 0.051%, ZrO 2 0.46%.

[0031] Grinding: crushing, grinding to -0.043mm accounts for 92%;

[0032] Wet magnetic separation: the magnetic field strength is 900mT, the pulsation frequency is 200r / min, wet strong magnetic separation can separate niobium-containing magnetic minerals from zirconium-containing non-magnetic minerals, and obtain niobium-containing magnetite concentrates and zirconium-containing tailings, making the niobium minerals initially rich set;

[0033] Niobium-containing magnetic concentrate flotation: use the combination of water glass and hydroxamic acid to obtain niobium concentrate by flotation of niobium-containing magnetic concentrate through a process of roughing, sweeping and beneficiation. Among them, the dosage of rough water glass is 500g / t, stirred for 1 minute, the dosage of hydroxamic acid is 100g / t, stirred for 5 minutes; the dosage of sweeping monohydroxamic acid is 50g / t; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com