A kind of compound fat simulant and preparation method thereof

A fat simulant, a composite technology, applied in the production/processing of edible oil/fat components, edible oil/fat, etc., to achieve the effects of good water holding capacity and rheological stability, enhanced water holding capacity, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A compound fat simulant, its composition and mass percentage are as follows:

[0047]

[0048] The composite additive is composite additive 1.

[0049] The preparation method of the above-mentioned composite fat simulant, the steps are as follows:

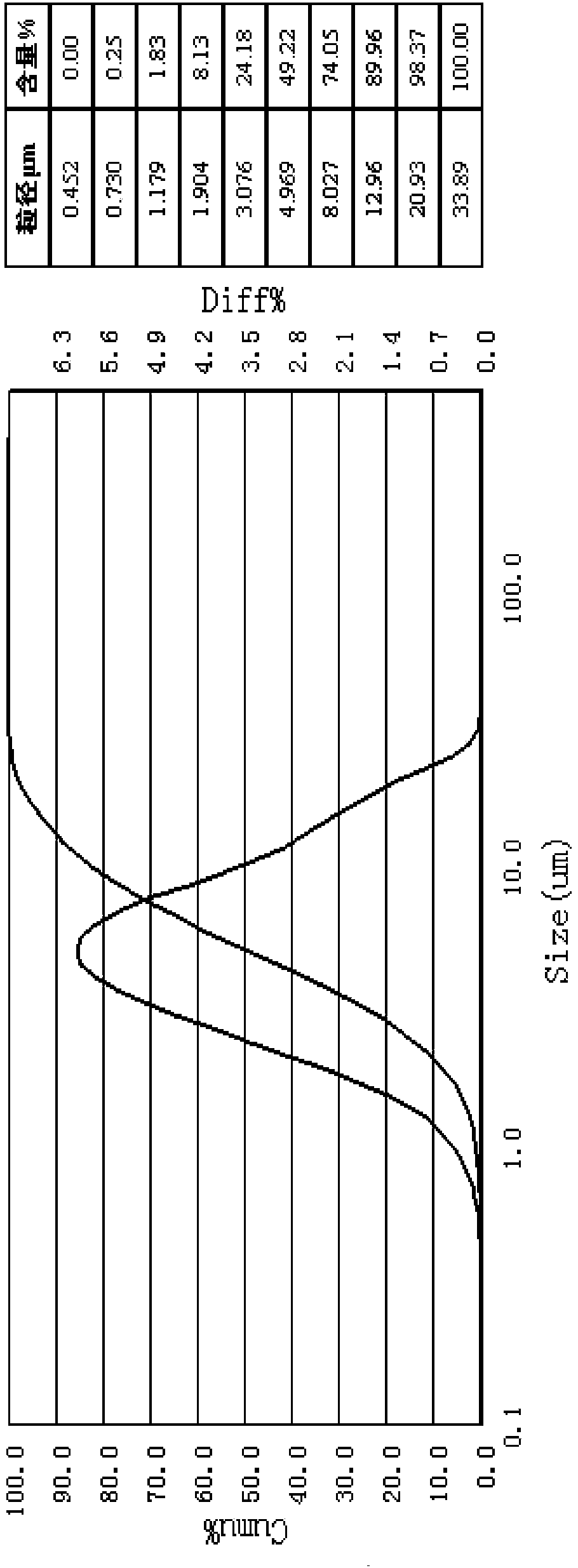

[0050] (1) Superfine pulverization and aging: After superfine pulverization of whey protein (protein content 50% to 100%), superfine protein powder with a particle size distribution mainly in the range of 600nm to 10μm is obtained, and the dissolved concentration is 0.10 g / mL whey protein dispersion, use citric acid to adjust the pH to 4.0, heat treatment in a constant temperature water bath at 85°C for 10 minutes, cool to room temperature, and then place it at 4°C for 10 hours to obtain an aged whey protein solution ;

[0051] (2) Micronization: micronize the protein dispersion obtained by aging at 10000r / min for 5 minutes to obtain a whey protein microparticle dispersion;

[0052] (3) Preparation of xanthan gum and p...

Embodiment 2

[0055] A compound fat simulant, its composition and mass percentage are as follows:

[0056]

[0057] The composite additive is composite additive 2.

[0058] The preparation method of the above-mentioned composite fat simulant, the steps are as follows:

[0059] (1) Superfine pulverization and aging: After superfine pulverization of whey protein (protein content 50% to 100%), superfine protein powder with a particle size distribution mainly in the range of 600nm to 10μm is obtained, and the dissolved concentration is 0.10 g / mL whey protein dispersion, use citric acid to adjust the pH to 6.5, heat treatment in a constant temperature water bath at 80°C for 20 minutes, cool to room temperature, and then place it at 4°C for 16 hours to obtain whey protein aged liquid ;

[0060] (2) Micronization: micronize the protein dispersion obtained by aging at 10000r / min for 5 minutes to obtain a whey protein microparticle dispersion;

[0061] (3) Preparation of xanthan gum and pectin...

Embodiment 3

[0064] A compound fat simulant, its composition and mass percentage are as follows:

[0065]

[0066] The composite additive is composite additive 1.

[0067] The preparation method of the above-mentioned composite fat simulant, the steps are as follows:

[0068] (1) Superfine pulverization and aging: After superfine pulverization of whey protein (protein content 50% to 100%), superfine protein powder with a particle size distribution mainly in the range of 600nm to 10μm is obtained, and the dissolved concentration is 0.15 g / mL whey protein dispersion, use citric acid to adjust the pH to 4.0, heat treatment in a 90°C constant temperature water bath for 35 minutes, cool to room temperature, and then place it at 4°C for 20 hours to obtain whey protein aged liquid ;

[0069] (2) Micronization: the aging protein dispersion was subjected to micronization treatment at 15000r / min for 9 minutes to obtain a whey protein microparticle dispersion;

[0070] (3) Preparation of xantha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com