Gradient ridge-waveguide distributed-feedback laser with high single-mode yield

A distributed feedback and distributed feedback technology, applied in the field of lasers, can solve the problems of long laser cavity, high threshold, and low diffraction efficiency of the second-order grating, so as to improve the yield of single-mode and solve the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

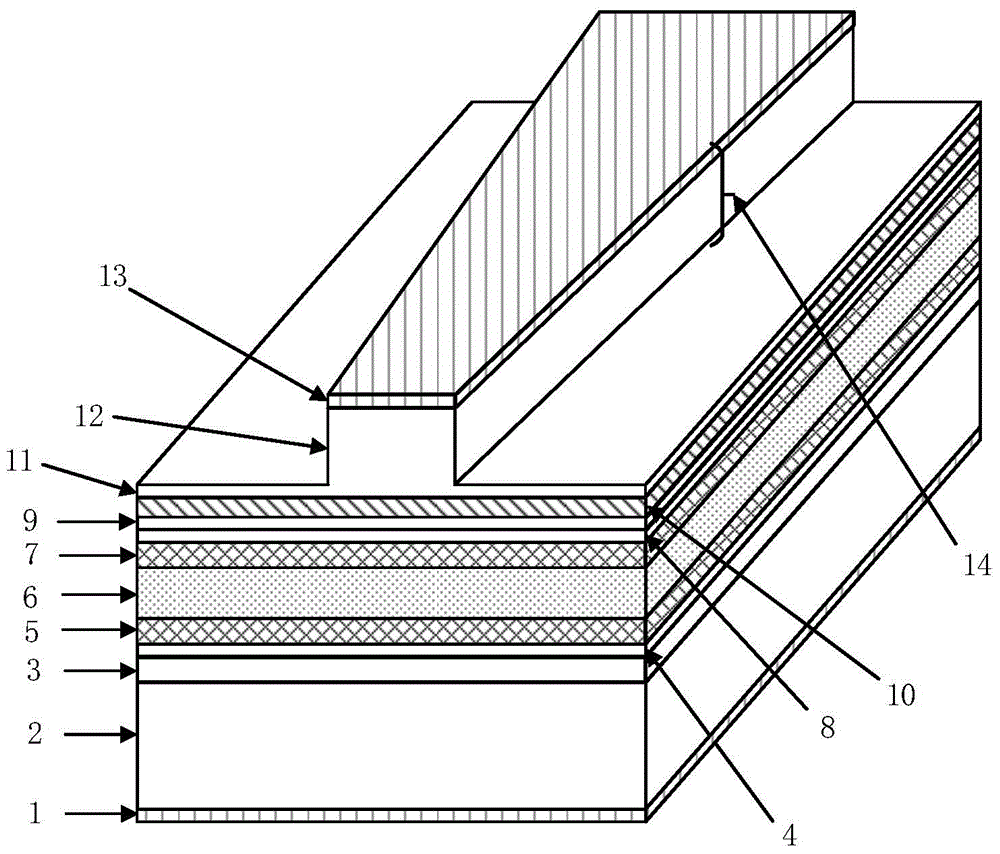

[0059] figure 1 It is a schematic diagram of the AlGaInAs / InP DFB semiconductor laser with a working wavelength of 1310nm. The laser has a resonant cavity. The resonant cavity includes from bottom to top: a substrate, a buffer layer, a first barrier layer, a first separate confinement layer, a quantum well active region, a second separate confinement layer, a second barrier layer, and a second barrier layer. A spacer layer and a second spacer layer; the Bragg grating is located in the grating layer between the first spacer layer and the second spacer layer. The resonant cavity has a laser output end surface, and the cavity length direction of the resonant cavity is perpendicular to the laser output end surface.

[0060] figure 1 Middle 1 and 13 are contact layers. The contact layer is used to contact the electrode layer metal to reduce the resistance of the electrical connection. The material of the contact layer is In. 0.53 Ga 0.47 As, the thickness of the contact layer is 200...

Embodiment 2

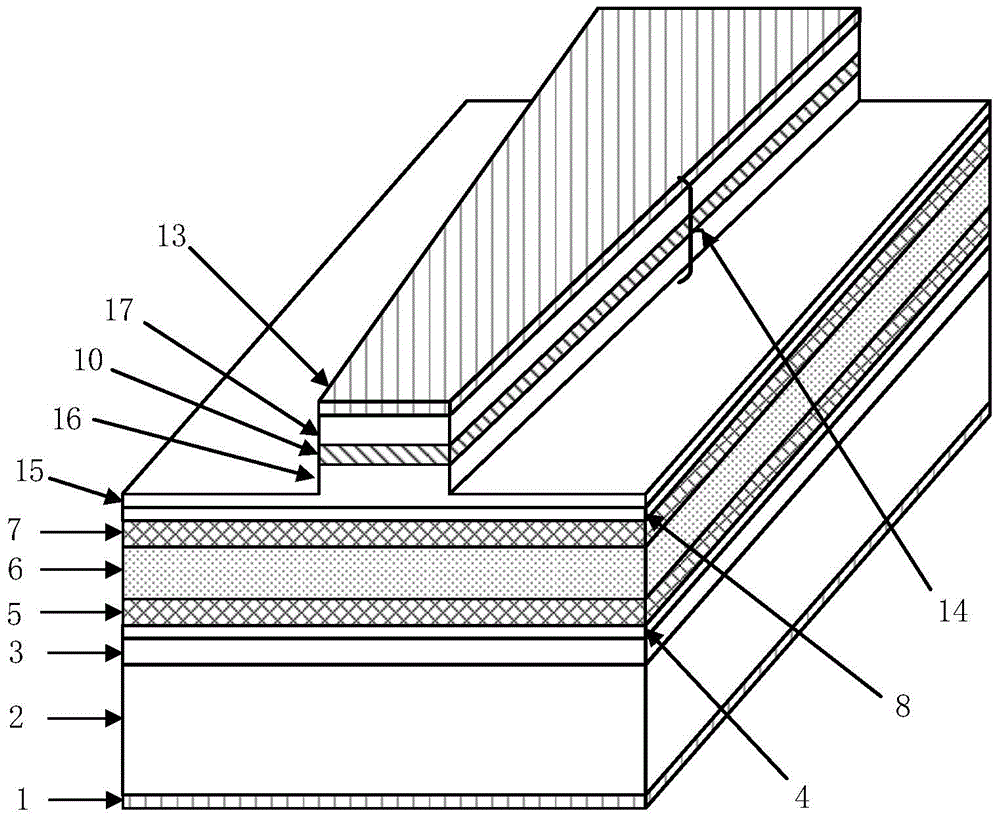

[0068] image 3 It is a schematic diagram of the structure of a 1310nm AlGaInAs / InP DFB semiconductor laser with a grating layer in the ridge. 1 and 13 in the figure are the contact layer; 2 is the substrate; 3 is the buffer layer, the material is InP, the thickness is 500nm; the ratio of 4 to 8 Is the first and second barrier layer, the material is In 0.52 Al 0.48 As, the thickness is 50nm; 5 and 7 are the first and second confinement layers respectively, the material is InAlGaAs, and the thickness is 100nm; 6 is the quantum well active region, which is composed of 8 well layers and 9 barrier layers stacked across , The material of each well layer is In 0.69 Al 0.16 Ga 0.15 As, the thickness is 5.5nm, the material of each barrier is In 0.52 Al 0.35 Ga 0.13 As, the thickness is 9nm; 9 is the spacer layer; 10 is the grating layer, the material is In 0.79 Ga 0.21 As 0.46 P 0.54 , The thickness is 30nnm, the grating period is 204.7nm, the material is InP, and the thickness is 50nm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com