Electronic error-proofing identifying counter

A kind of counter and electronic technology, applied in the direction of counting mechanism/items, instruments, etc., can solve the problem of inflow of defective products, and achieve the effect of high reliability and fast inspection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

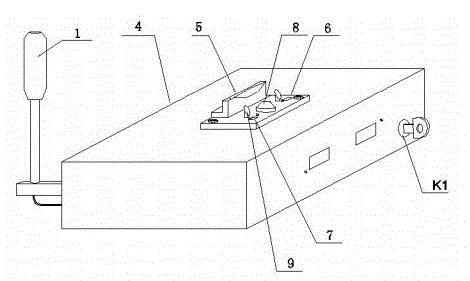

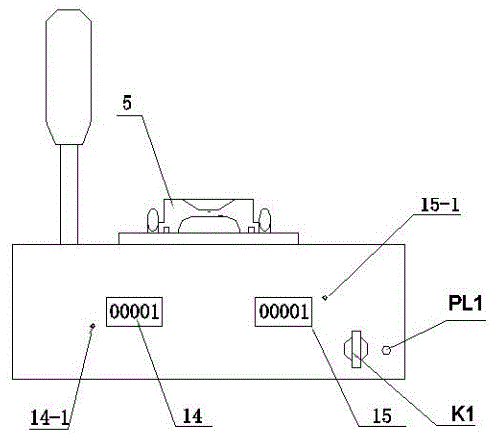

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] The electronic error proofing counter includes a test bench 4 and a test seat 6 . There is a detection circuit in the test bench, and a signal lamp bracket 2 is provided at the rear of the test bench 4. The signal lamp 1 is installed on the bracket 2. The signal lamp is connected to the detection circuit board in the test bench through the signal line 3, and the buzzer is installed on the test bench. Desk interior.

[0025] At least two inductors are installed on the test seat, the position of at least one inductor matches the common feature point of the workpiece, and the position of at least one inductor matches the distinguishing feature point of the workpiece. The sensor is a proximity switch, a pressure switch or a reflective infrared sensor. When an object approaches and touches the switch, it is triggered to work.

[0026] Two groups of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com