Water pump automatic test system

An automatic test system and water pump technology, applied in pump testing, machine/engine, liquid variable capacity machinery, etc., can solve the problems of narrowing the application scope of water pumps, waste of resources, and time-consuming, etc., and achieve a friendly human-computer interaction interface. Easy to use and manage, with a good degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

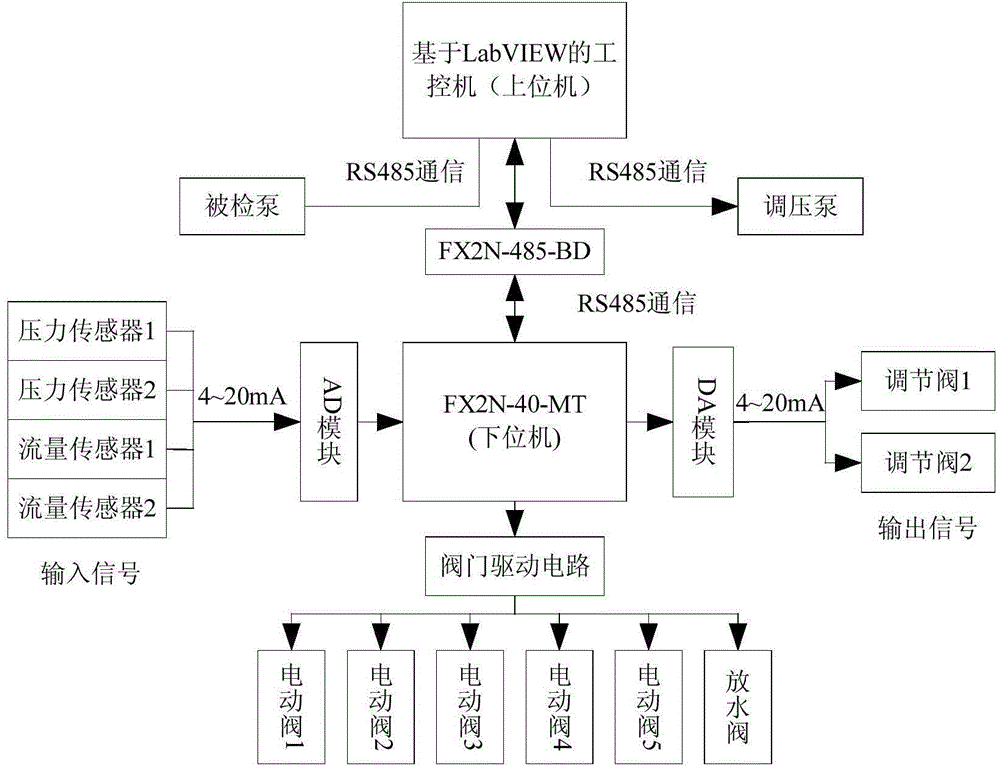

[0019] The present invention is an automatic test system for water pump performance detection, which is configured as follows:

[0020] serial number device name Specification quantity unit Remark 1 PLC FX2N-40MT 1 tower 2 Analog input module FX2N-4AD 1 indivual Each module contains 4 inputs 3 Analog output module FX2N-4DA 1 indivual Each module contains 4 outputs 4 driver module Valve drive circuit 1 indivual Each module contains 8 channels 5 switching power supply DC24 V 2A output 2 indivual For DA module and AD module and drive circuit 6 transformer AC220 V Turn to AC24 V 1 indivual 7 communication hardware FX2N-485-BD 1 indivual 8 programming software LabVIEW 1 set

[0021] Further illustrate the present invention below in conjunction with accompanying drawing.

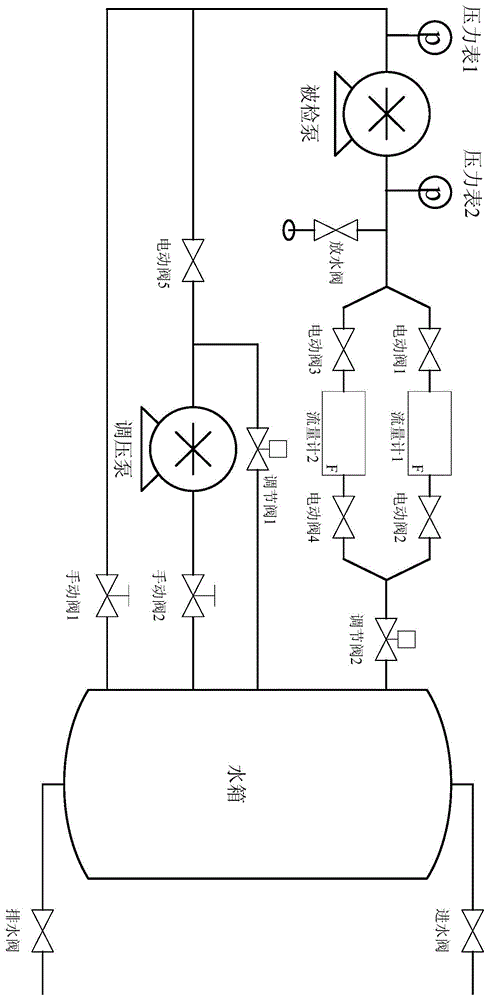

[0022] refer to figure 1 As shown, the system consists of three parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com