Method for adjusting and controlling AlCoCrFeNi high-entropy alloy structure

A high-entropy alloy and microstructure technology, which is applied in the field of regulating the microstructure of AlCoCrFeNi high-entropy alloys, can solve the problems of high operating environment requirements and inability to operate in the atmosphere, and achieves the effect of a simple and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

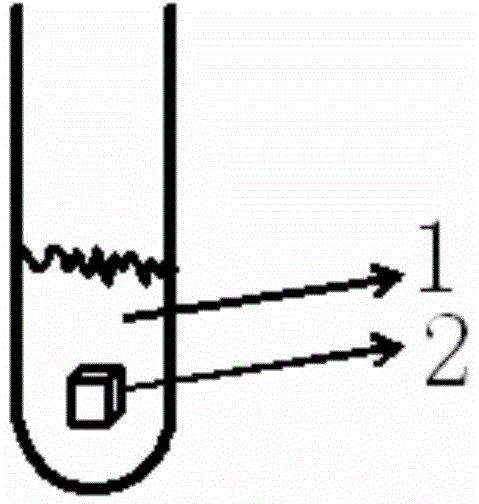

[0029] This embodiment is a method for regulating the structure of AlCoCrFeNi high-entropy alloy. The experimental equipment used is a high-frequency induction power supply. The specific process is:

[0030] Step 1, the preparation of purifying agent:

[0031] The first step is to weigh the powdered Na with a mass ratio of 1:1. 2 B 4 o 7 and powdered Na 2 SiO 3 . In the present embodiment, take the Na of 20g 2 B 4 o 7 and 20g Na 2 SiO 3 . Na to be weighed 2 B 4 o 7 and Na 2 SiO 3 Placed in two corundum crucibles respectively. will hold Na 2 B 4 o 7 and Na 2 SiO 3 The two corundum crucibles were respectively placed in a muffle furnace, and the temperature of the two corundum crucibles was raised to 200° C. with the furnace and kept for 2 hours. After the heat preservation is completed, the temperature of the muffle furnace is raised to 400° C. and the temperature is maintained for 2 hours. After the heat preservation is finished, the two corundum crucib...

Embodiment 2

[0041] This embodiment is a method for regulating the structure of AlCoCrFeNi high-entropy alloy. The experimental equipment used is a high-frequency induction power supply. The specific process is:

[0042] Step 1, the preparation of purifying agent:

[0043] The first step is to weigh the powdered Na with a mass ratio of 1:1. 2 B 4 o 7 and powdered Na 2 SiO 3 . In the present embodiment, take the Na of 25g 2 B 4 o 7 and 25g Na 2 SiO 3 . Na to be weighed 2 B 4 o 7 and Na 2 SiO 3 Placed in two corundum crucibles respectively. will hold Na 2 B 4 o 7 and Na 2 SiO 3 The two corundum crucibles were respectively placed in a muffle furnace, and the temperature of the two corundum crucibles was raised to 300° C. with the furnace and kept for 3 hours. After the heat preservation is over, the temperature of the muffle furnace is raised to 460° C. and the temperature is maintained for 3 hours. After the heat preservation is finished, the two corundum crucibles a...

Embodiment 3

[0053] This embodiment is a method for regulating the structure of AlCoCrFeNi high-entropy alloy. The experimental equipment used is a high-frequency induction power supply. The specific process is:

[0054] Step 1, the preparation of purifying agent:

[0055] The first step is to weigh the powdered Na with a mass ratio of 1:1. 2 B 4 o 7 and powdered Na 2 SiO 3 . In the present embodiment, take the Na of 30g 2 B 4 o 7 and 30g Na 2 SiO 3 . Na to be weighed 2 B 4 o 7 and Na 2 SiO 3 Placed in two corundum crucibles respectively. will hold Na 2 B 4 o 7 and Na 2 SiO 3 The two corundum crucibles were respectively placed in a muffle furnace, and the temperature of the two corundum crucibles was raised to 300° C. with the furnace and kept for 2.5 hours. After the heat preservation is completed, the temperature of the muffle furnace is raised to 500° C. and the temperature is maintained for 2.5 hours. After the heat preservation is finished, the two corundum cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com