Environment-friendly black ink

A black and ink technology, applied in the field of ink, can solve the problems of unsatisfactory computer graphics, unsmooth writing, complicated process, etc., and achieve good ecological safety and compatibility, smooth and durable writing, and high surface activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

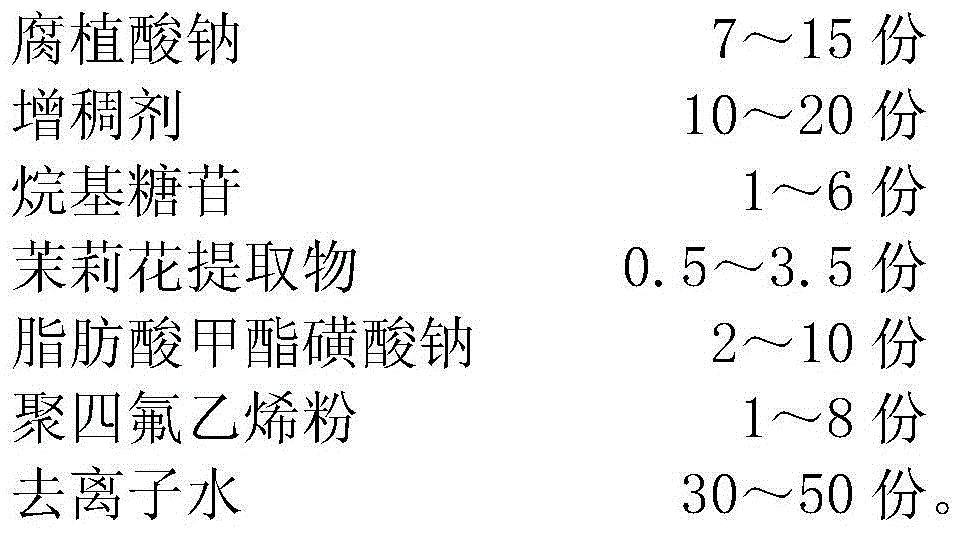

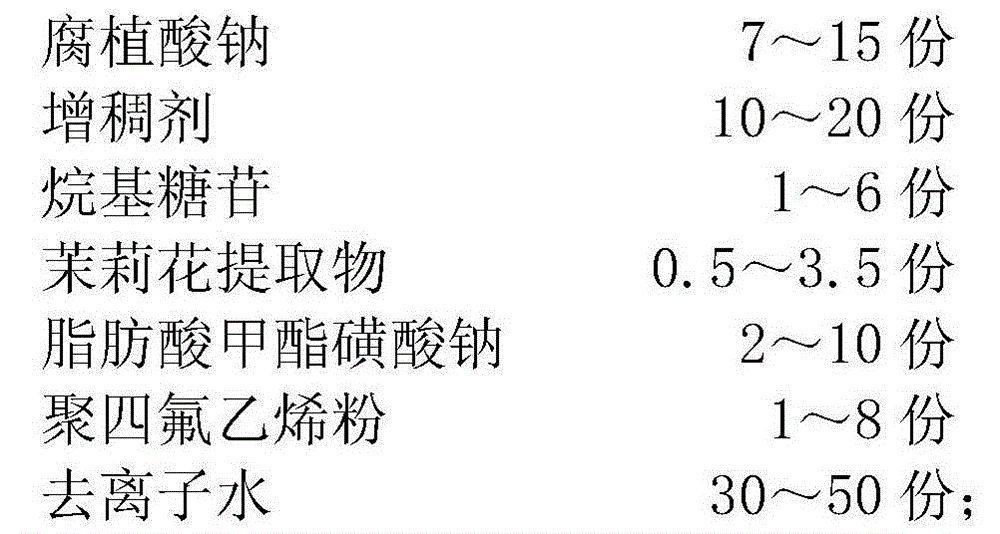

Method used

Image

Examples

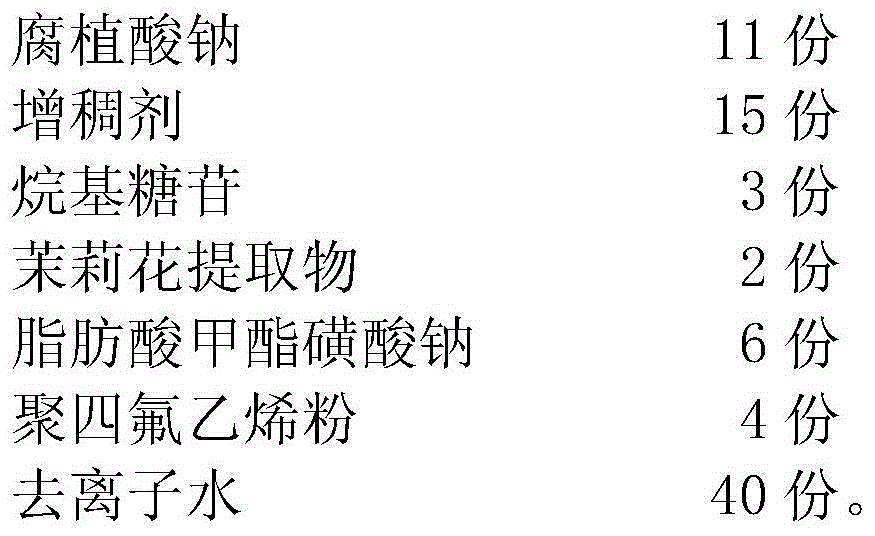

Embodiment 1

[0024] Add 15 parts by weight of deionized water prepared into the stirred tank, keep the water temperature in the tank at 50°C, add 13 parts by weight of sodium humate under stirring to completely dissolve it, then add 6 parts by weight of alkyl glycoside, 10 parts by weight 1 part of sodium fatty acid methyl ester sulfonate and 1 part by weight of polytetrafluoroethylene powder with a particle diameter of 3 μm, stirred and homogenized for 30 min, and finally added deionized water of remaining 15 parts by weight, 0.5 parts by weight of jasmine flower extract and 20 parts by weight of starch, Stirring was continued for another 20 minutes, cooled to room temperature, allowed to stand, and filtered to obtain the product.

Embodiment 2

[0026] Add 17.5 parts by weight of deionized water prepared into the stirred tank, keep the water temperature in the tank at 55°C, add 15 parts by weight of sodium humate under stirring to completely dissolve it, then add 2 parts by weight of alkyl glucoside, 8 parts by weight 1 part of sodium fatty acid methyl ester sulfonate and 6 parts by weight of polytetrafluoroethylene powder with a particle diameter of 5 μm, stirred and homogenized for 35 min, and finally added deionized water of remaining 17.5 parts by weight, 1.5 parts by weight of jasmine flower extract and 18 parts by weight of gelatin, Stirring was continued for 15 minutes, cooled to room temperature, allowed to stand, and filtered to obtain the product.

Embodiment 3

[0028] Add 20 parts by weight of prepared deionized water into the stirred tank, keep the water temperature in the tank at 55°C, add 11 parts by weight of sodium humate under stirring to completely dissolve it, then add 3 parts by weight of alkyl glycosides, 6 parts by weight 1 part of sodium fatty acid methyl ester sulfonate and 4 parts by weight of polytetrafluoroethylene powder with a particle size of 7 μm, stirred and homogenized for 40 min, and finally added the remaining 20 parts by weight of deionized water, 2 parts by weight of jasmine flower extract and 15 parts by weight of alginic acid sodium, continue to stir for 10 minutes, cool down to room temperature, let stand, and filter to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com