Biodegradable physical hydrogel capable of rapid gelation in situ and preparation method thereof

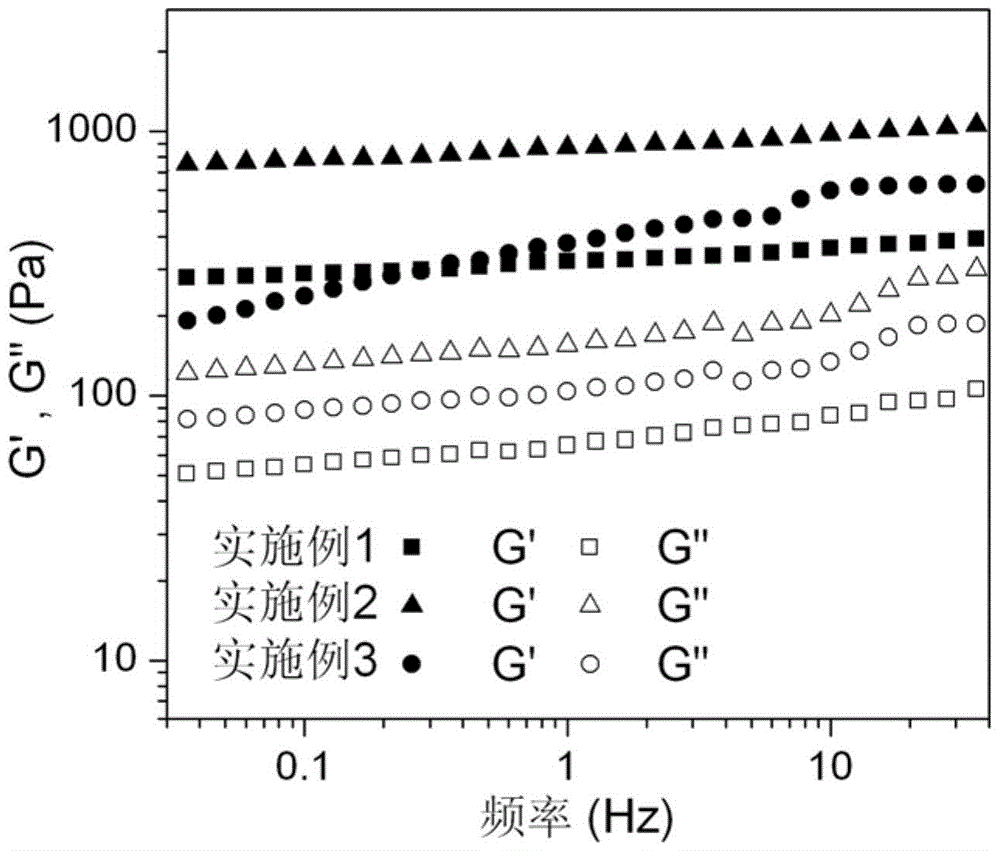

A technology of gelation and physical water, which is applied in the direction of medical preparations of non-active ingredients, pharmaceutical formulas, medical science, etc., can solve the problem of losing in-situ gelation performance, slow in-situ gelation speed, and affecting biomedicine Application and other issues, to achieve the effect of improving biocompatibility, fast gelation speed, good strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way. Reagents and medicines used in the preparation of hydrogel in the present invention: PEG is purchased from Aladdin Company; lactide is purchased from Praque Company, and secondary crystallized after being dissolved in ethyl acetate, for subsequent use; catalyst stannous octoate is purchased from Sigma Company; solvent toluene It is analytically pure in Chinese medicine, distilled to remove water with sodium metal, and set aside.

[0036] Step 1: Preparation of Component A

[0037]The synthesis reference of component A was carried out by Kim MS et al., J.Polym.Sci., Part A: Polym.Chem.2004, 42, 5784-5793. Add a certain amount of single-end hydroxyl-terminated PEG and lacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com