Polyvinyl chloride material for manufacturing ping-pong balls and preparation method thereof

A polyvinyl chloride and table tennis technology, which is applied to sports accessories and other directions, can solve the problems of not being found, the performance of table tennis is difficult to reach the standard, and the production efficiency cannot be compared with the existing technology, so as to increase the cost of equipment and eliminate potential safety hazards. , the preparation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

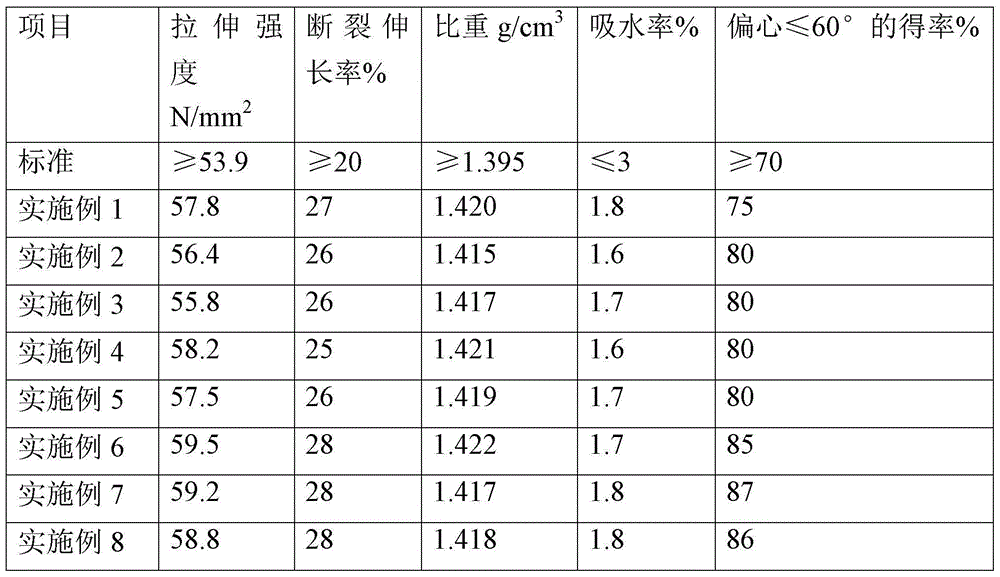

Examples

Embodiment 1

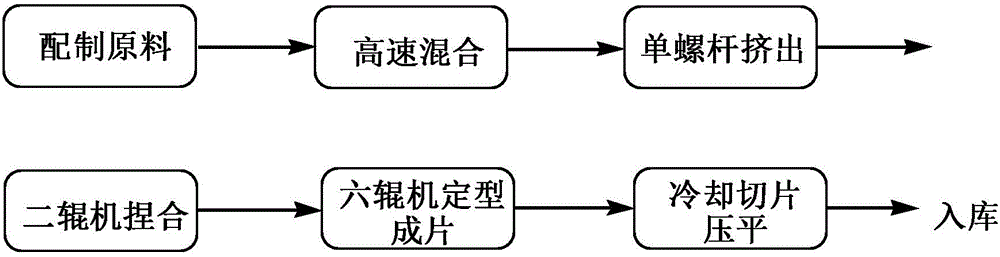

[0032] see figure 1 , as an embodiment of the present invention, the preparation method described for making the polyvinyl chloride material of table tennis comprises the following steps:

[0033] 1) Take by weighing 100kg of polyvinyl chloride (polymerization degree 810), 15kg of calcium carbonate with a particle diameter of 200nm, 15kg of camphor powder, 7kg of calcium-zinc composite stabilizer, 20kg of MBS resin, and 10g of ultramarine blue.

[0034] 2) Mix the raw materials obtained in step 1) in a high-speed mixer, first mix at a low speed, and then mix at a high speed. The material is discharged into the cooling mixer for cooling, and the material is discharged after being cooled to 40°C.

[0035] 3) Extrude the mixed raw materials with a single-screw extruder at a temperature of 135 to 160°C; then introduce the extruded material into a two-roller machine for kneading and sheet production at a kneading temperature of 160°C.

[0036] 4) Pull the sheet to a six-roll mach...

Embodiment 2

[0040] see figure 1 , as an embodiment of the present invention, the preparation method described for making the polyvinyl chloride material of table tennis comprises the following steps:

[0041] 1) take polyvinyl chloride (polymerization degree 1020) 110kg, particle diameter is the calcium carbonate 12kg of 800nm, dicyclohexyl terephthalate 15kg, calcium-zinc composite stabilizer 8kg, MBS resin 10kg and chlorinated polyethylene 10kg, Lemon yellow 30g.

[0042] 2) Mix the raw materials obtained in step 1) in a high-speed mixer, first mix at a low speed, and then mix at a high speed. The material is discharged into the cooling mixer for cooling, and the material is discharged after being cooled to 45°C.

[0043] 3) Extrude the mixed raw materials with a single-screw extruder at a temperature of 135-160°C; then introduce the extruded material into a two-roller machine for kneading and extruding into sheets at a kneading temperature of 170°C.

[0044] 4) Pull the sheet materi...

Embodiment 3

[0047] see figure 1 , as an embodiment of the present invention, the preparation method described for making the polyvinyl chloride material of table tennis comprises the following steps:

[0048] 1) take polyvinyl chloride (polymerization degree 1200) 80kg, particle diameter is the calcium carbonate 15kg of 500nm, camphor powder 9kg and dicyclohexyl terephthalate 8kg, calcium-zinc composite stabilizer 10kg, chlorinated polyethylene 25kg, Titanium dioxide 200g.

[0049]2) Mix the raw materials obtained in step 1) in a high-speed mixer, first mix at a low speed, and then mix at a high speed. The material is discharged into the cooling mixer for cooling, and the material is discharged after being cooled to 38°C.

[0050] 3) Extrude the mixed raw materials with a single-screw extruder at an extrusion temperature of 135-160°C; then introduce the extruded material into a two-roller machine for kneading and sheet production at a kneading temperature of 155°C.

[0051] 4) Pull the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com