Method for preparing polyurethane binder for flexible printing composite ink

A technology of polyurethane adhesive and polyurethane resin, which is applied in ink, application, and home appliances, etc., can solve the problems of easy release of formaldehyde, thermal sticking and freezing of polyamide ink, etc., achieve large cohesive energy of urea bonds, meet the requirements of use, The effect of good adhesion fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

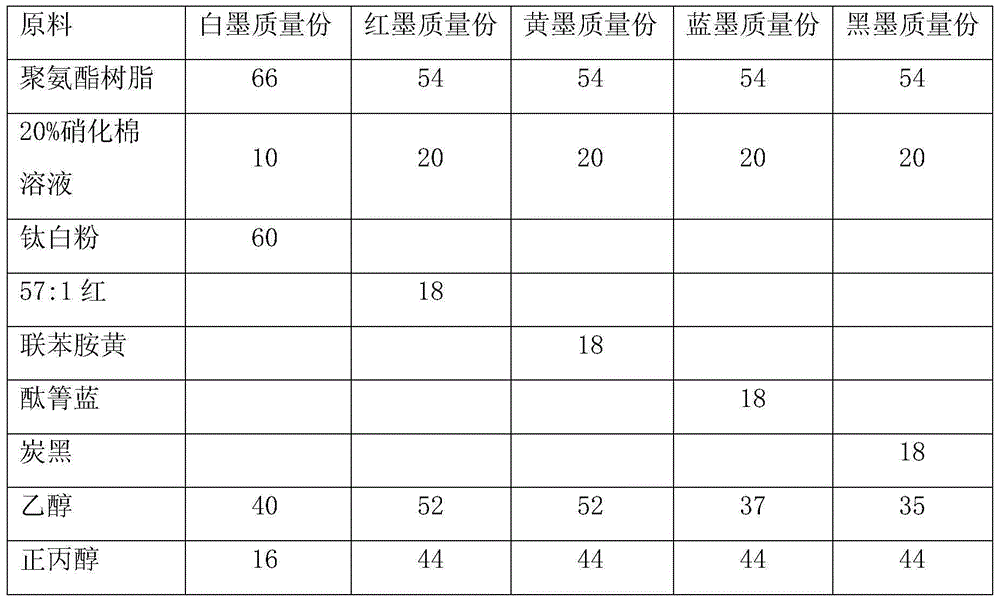

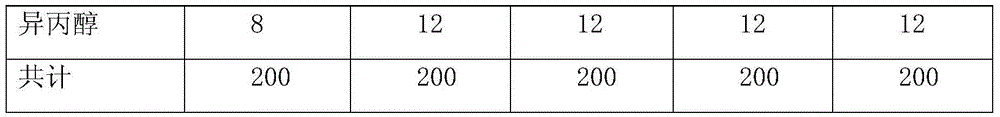

[0023] The embodiment of the present invention provides a method for preparing an adhesive for flexographic composite ink, which is a method for preparing an alcohol-soluble polyurethane resin adhesive. The method includes the following steps:

[0024] Preparation of NCO-terminated prepolymers:

[0025] After mixing 71-84 parts by mass of polyether diol, 0.05-0.2 parts by mass of catalyst, and 16-29 parts by mass of diisocyanate, and reacting at 50-120°C for 2-4 hours, the obtained reaction product is NCO-terminated prepolymer, the structure of the NCO-terminated prepolymer is: OCN-B-(-NH-CO-O-R1-O-CO-NH-)m-B-NCO; wherein, R1 is methylene group, ether group, cyclohexyl or aromatic hydrocarbon group, B is methylene, aromatic hydrocarbon group or alicyclic hydrocarbon group;

[0026] Chain extension synthesis:

[0027] Prepare another container (such as a flask or a reaction kettle), add 0.7-1.4 parts by mass of amine chain extender, 67-73 parts by mass of alcohol solvent, and...

Embodiment 1

[0038] This embodiment provides a method for preparing polyurethane resin for alcohol-soluble flexographic composite ink, which specifically includes the following steps:

[0039] (1) Preparation of terminal NCO-based prepolymers:

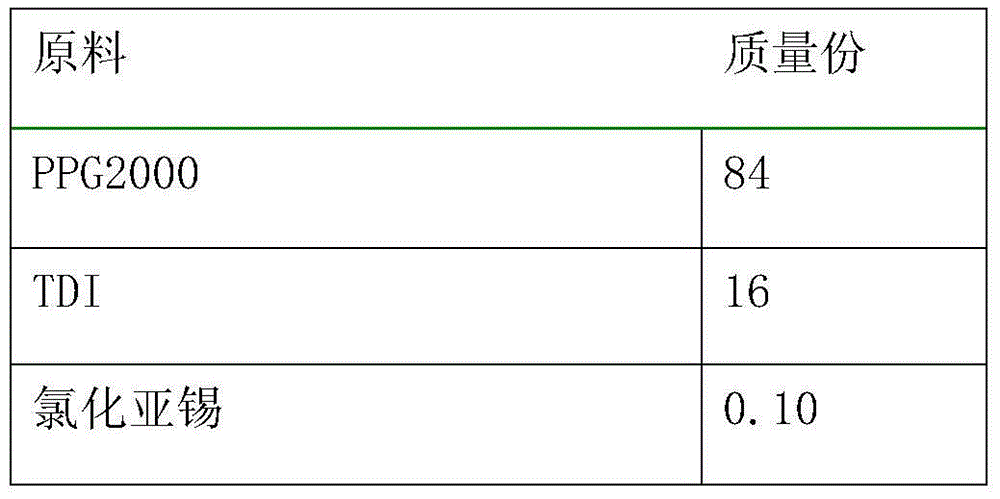

[0040] raw material

[0041] After mixing 72 parts by mass of polyether diol, 0.05 parts by mass of catalyst, and 28 parts by mass of MDI, react at 80°C for 3 hours to obtain a prepolymer with an NCO of 6.4;

[0042] (2) chain extension synthesis:

[0043] raw material

[0044] In addition, prepare a flask, add 1.3 parts by mass of ethylenediamine, 70 parts by mass of isopropanol, stir evenly, and drop the prepolymer prepared in 28.7 parts by mass (1) into the above-mentioned mixed solution for 5 minutes to carry out the chain extension reaction. The temperature is controlled below 30°C, and the polyurethane resin is obtained after 2.5 hours of reaction, with a viscosity of 3000mpa.s and a solid content of 31.0%;

Embodiment 2

[0046] This embodiment provides a method for preparing polyurethane resin for alcohol-soluble flexographic composite ink, which specifically includes the following steps:

[0047] (1) Preparation of terminal NCO-based prepolymers:

[0048] (2)

[0049]

[0050] Mix 84 parts by mass of PPG2000, 0.1 parts by mass of catalyst, and 16 parts by mass of TDI, and react at 80°C for 2 hours to obtain a prepolymer with an NCO value of 4.2;

[0051] (2) chain extension synthesis:

[0052] raw material

[0053] Prepare another flask, add 1.4 parts by mass of 1,6 hexamethylenediamine and 70 parts by mass of ethanol, stir evenly, put 28.6 parts by mass of the prepolymer prepared in (1) into the above mixed solution within 30 minutes for chain extension reaction , the reaction temperature is controlled below 40°C, the polyurethane resin is obtained after 2 hours of reaction, the viscosity is 1500mpa.s, and the solid content is 30.2%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com