Nanoparticles and maleic anhydride composite grafted polyolefin elastomer and its preparation

A polyolefin elastomer and nanoparticle technology, applied in the field of polymers, can solve the problems of toughened nylon processability, high degree of crosslinking of grafts, loss of nylon tensile strength, etc., to improve fluidity and toughness Efficiency, improvement of grafting efficiency, and improvement of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

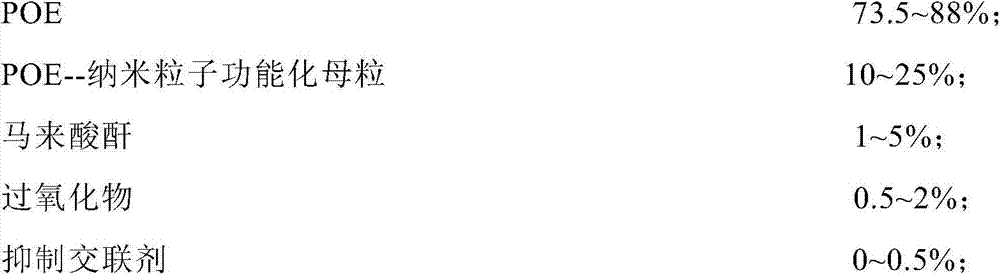

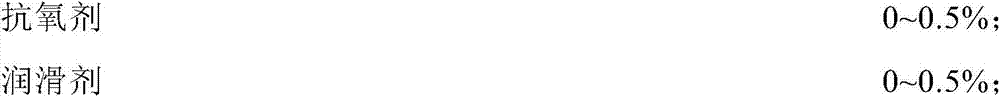

Method used

Image

Examples

Embodiment 1

[0035] According to the formula in Table 1, each component was weighed for subsequent use, and the POE used for preparing the POE-nanoparticle functionalized masterbatch was added from the main feeding port of the twin-screw extruder, and the three used POE-nanoparticle functionalized masterbatches were prepared. Ethylamine, antioxidant 1076 and antioxidant 168, microcrystalline paraffin, ethyl benzoate surface-modified nano-montmorillonite were added from the feeding port on the second side, and ultrasonic waves were introduced at the position immediately behind the feeding port on the second side Generating equipment, ultrasonic power is 600 ~ 1000W, through reactive extrusion to obtain POE-nanoparticle functionalized masterbatch;

[0036] After the POE for preparing polyolefin elastomer and the POE-nanoparticle functionalized masterbatch are uniformly mixed by a high-speed mixer, they are added from the main feeding port of the twin-screw extruder, and the maleate used for p...

Embodiment 2

[0038]According to the formula in Table 1, each component was weighed for subsequent use, and the POE used for preparing the POE-nanoparticle functionalized masterbatch was added from the main feeding port of the twin-screw extruder, and the three used POE-nanoparticle functionalized masterbatches were prepared. Ethylamine, antioxidant 1076 and antioxidant 168, microcrystalline paraffin, ethyl benzoate surface-modified nano-montmorillonite were added from the feeding port on the second side, and ultrasonic waves were introduced at the position immediately behind the feeding port on the second side Generating equipment, ultrasonic power is 600 ~ 1000W, through reactive extrusion to obtain POE-nanoparticle functionalized masterbatch;

[0039] After the POE for preparing polyolefin elastomer and the POE-nanoparticle functionalized masterbatch are uniformly mixed by a high-speed mixer, they are added from the main feeding port of the twin-screw extruder, and the maleate used for pr...

Embodiment 3

[0041] It is standby to weigh each component according to the formula of Table 1, the POE used for preparing POE-nanoparticle functionalized masterbatch is added from the main feeding port of the twin-screw extruder, and the used POE for preparing POE-nanoparticle functionalized masterbatch is added. The oxide is added from the first side feed port, and the triethylamine, antioxidant 1076 and antioxidant 168, microcrystalline paraffin, and ethyl benzoate surface-modified nano-membrane used for the preparation of POE-nanoparticle functional masterbatch are added. The desoiling is added from the feeding port on the second side, and the ultrasonic generating equipment is introduced at the position close to the feeding port on the second side. The ultrasonic power is 600-1000W, and the POE-nanoparticle functionalized masterbatch is obtained through reaction extrusion;

[0042] After the POE for preparing polyolefin elastomer and the POE-nanoparticle functionalized masterbatch are u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com