Water removing method and water removing apparatus for high temperature emulsion explosive production line explosive cartridge

A high-temperature emulsification and production line technology, which is applied in the direction of explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of increasing the manufacturing cost of packaging boxes, moisture deformation of product packaging boxes, and moisture deformation of packaging boxes, achieving low cost and significant dehumidification effect , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiment of the present invention: the method for removing water from the drug coils of the high-temperature emulsion explosive production line, first vibrating the drug coils transported from the cooling water pool, so that the water droplets attached to the drug coils fall off under the action of the exciting force; The dry hot air blows and heats the vibrating rolls. The pressure of the hot air is 0.4MPa and the temperature is 50°C, which accelerates the rapid volatilization of moisture on the surface of the rolls, thereby realizing the purpose of removing water from the rolls of the high-temperature emulsion explosive production line. .

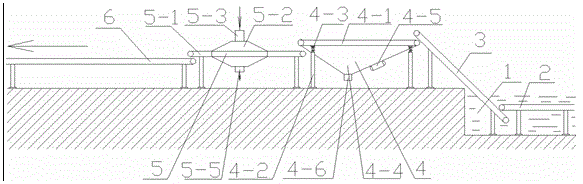

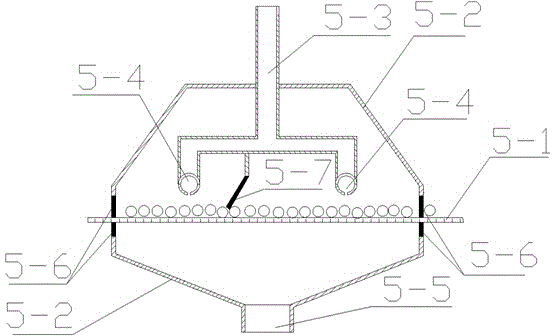

[0015] The structure of the water removal device for the high temperature emulsion explosive production line is as follows: figure 1 As shown, it includes a medicine roll conveyor 2 in the cooling pool 1, an inclined conveyor 3 is provided at the end of the medicine roll conveyor 2 in the pool, and a vibrating conveyor 4 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com