Lightweight quick setting top-caving area filling material

A filling material and high caving area technology, which is applied in the field of light and fast-setting high caving area filling materials, can solve the problems of roadway high caving area, gas overrun, high price, etc., and achieves the effect of satisfying filling requirements and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A lightweight quick-setting high-risk area filling material, which is composed of main material A and main material B, wherein the main material A is composed of sulphoaluminate cement, fly ash, water reducer, accelerator , foaming agent and dispersant, the main ingredient B is composed of gypsum, lime, water reducer, accelerator, dispersant and foaming agent;

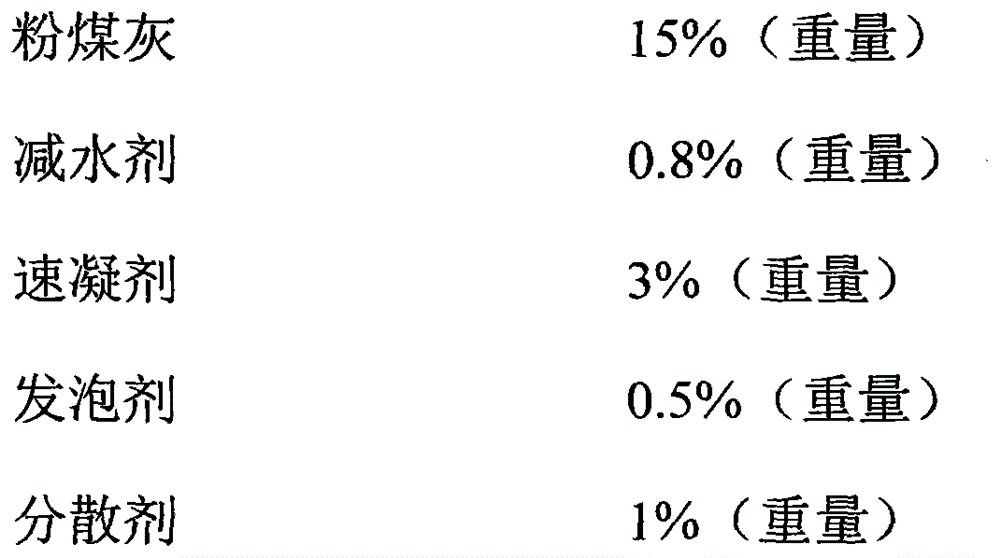

[0018] The scope of each composition in the main ingredient A is:

[0019]

[0020] The sum of the various ingredients is 100% (weight);

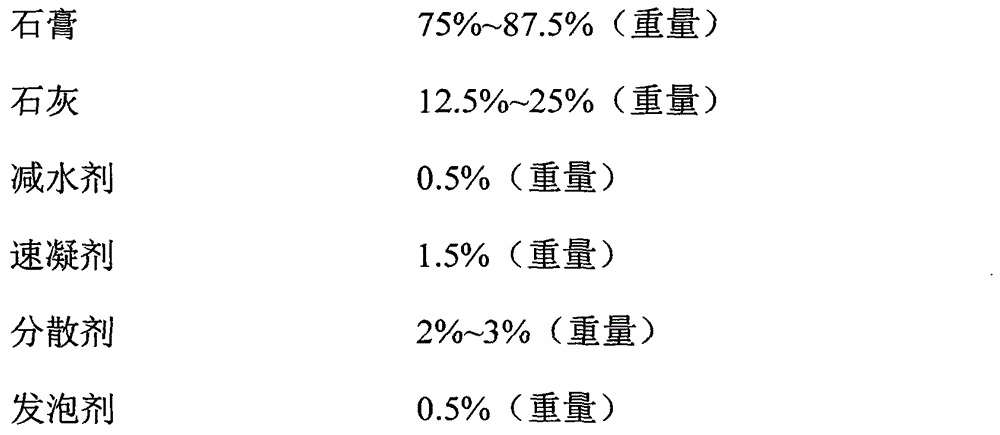

[0021] The scope of the various components of the main ingredient B is:

[0022]

[0023] The sum of the various ingredients is 100% by weight.

Embodiment 2

[0025] According to the components of the above-mentioned Example 1, during engineering construction, the mixed materials A and B are mixed with water respectively, and the water-cement ratio is 1:1-1.5:1, and then the two materials are mixed by using a pneumatic two-liquid grouting pump. According to 1:1 mixing, the two components are fully mixed through a mixer, and injected into the roof fall area. The mixed slurry can lose fluidity in 5 minutes, and then expand and solidify to form a light filling body. It can not only prevent the secondary collapse of the roof, but also prevent the accumulation of gas, thereby completely eliminating the hazards caused by the roof fall area to the mine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com