Superplastic forming/diffusion bonding forming method of titanium alloy parts with large curvature and complex profile

A diffusion connection and superplastic forming technology, applied in the field of sheet metal and thermal processing, can solve the problems of increasing production difficulty, increasing ejection and pressing devices, and increasing production costs, so as to achieve reduced production costs, high component dimensional accuracy, and High design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the invention will be further described in conjunction with the accompanying drawings and specific embodiments.

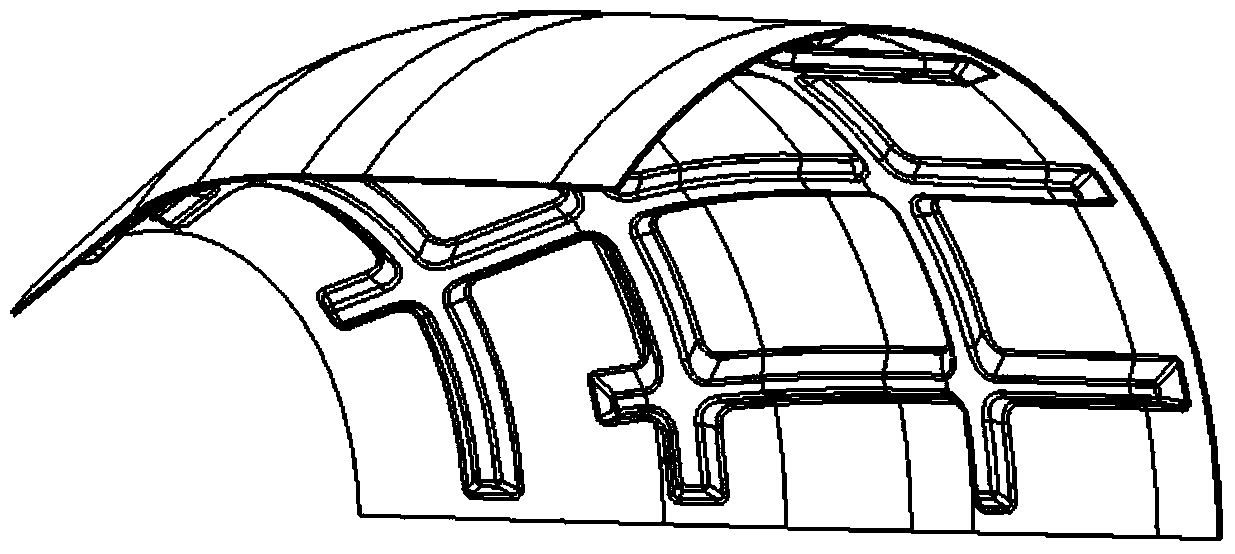

[0027] The titanium alloy part is a typical large-curvature double-layer structure part, and its shape and size are as follows figure 1 As shown, the outer layer is a 2mm thick titanium plate, and the inner layer is a 1mm thick titanium plate.

[0028] (1) Sheet metal preforming

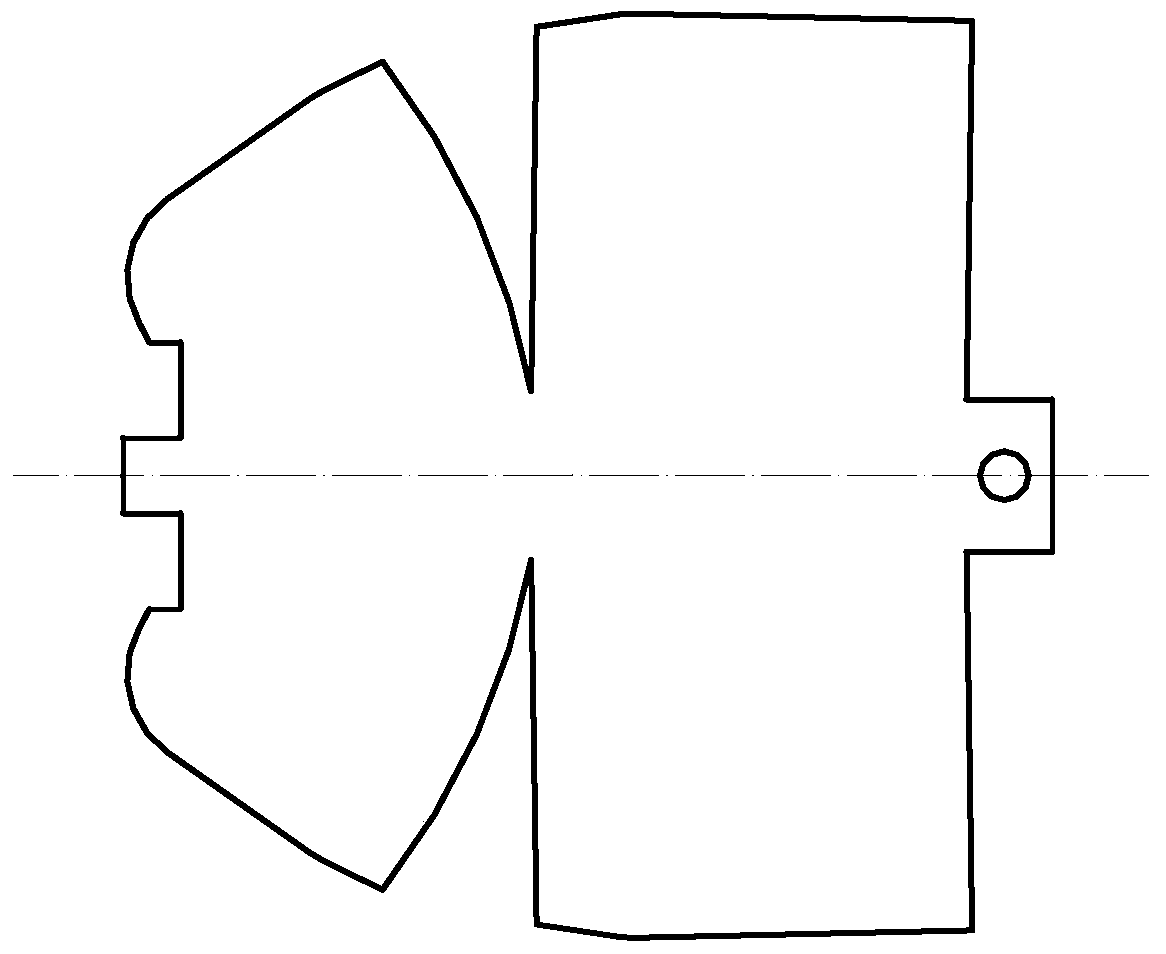

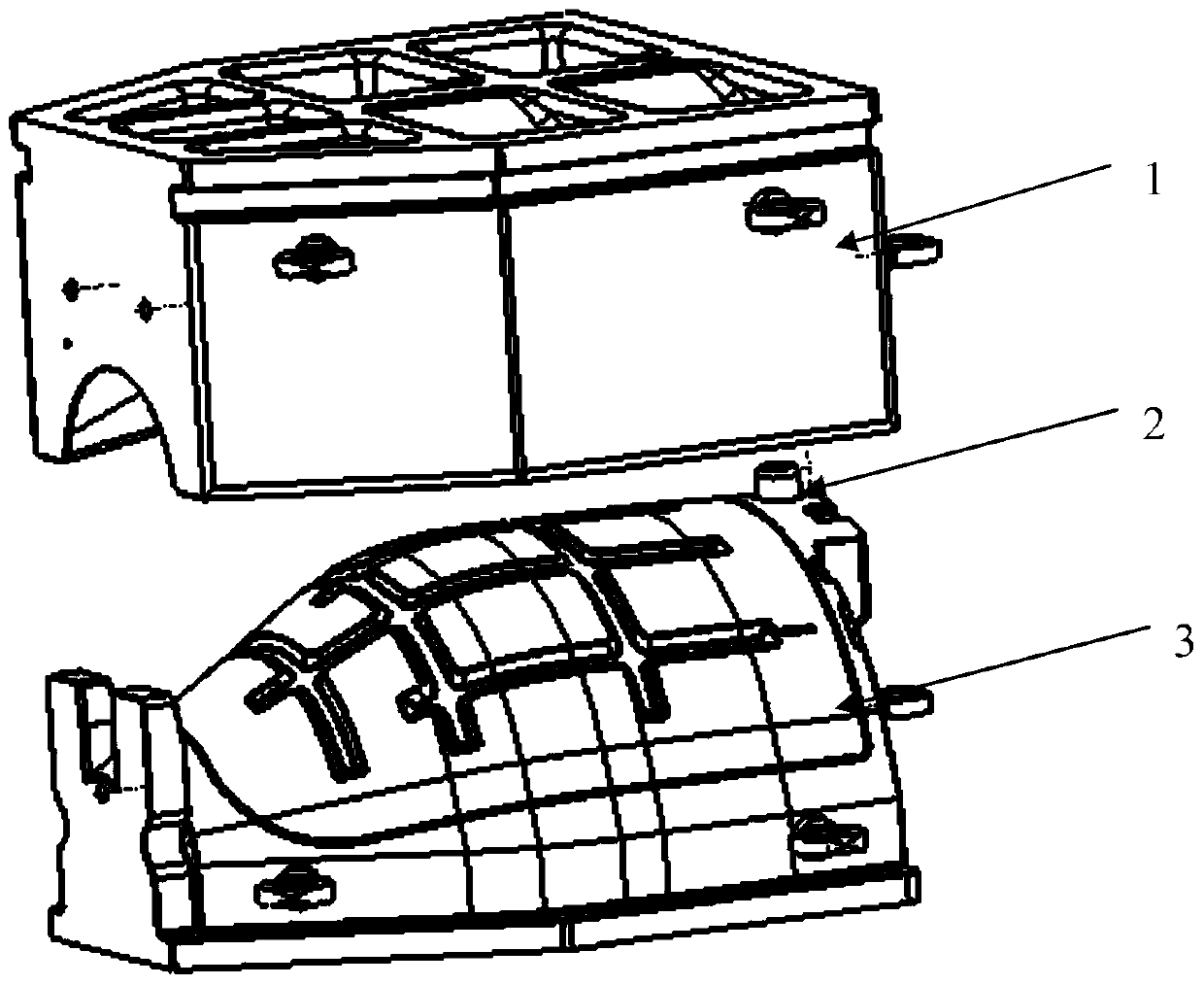

[0029] Calculate the blanking size according to the external dimensions of the final formed part, and reasonably remove excess sheet material at the easy-to-fold parts, as follows figure 2 As shown, after forming without blank holder, the blank with no wrinkle on the surface can be obtained, and a reasonable gap for the subsequent welding process is reserved, and the positioning surfaces at both ends are reserved; the mold is as follows image 3 Put it into the thermoforming machine and raise the temperature to 800-820°C, put the inner and outer plates into the mold respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com