Heat exchanger, and especially manufacturing method of adsorption type heat exchanger

A technology of heat exchanger and manufacturing method, which is applied in the directions of heat exchanger fixing, heat exchange equipment, manufacturing tools, etc., can solve problems such as reducing the efficiency of adsorption heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

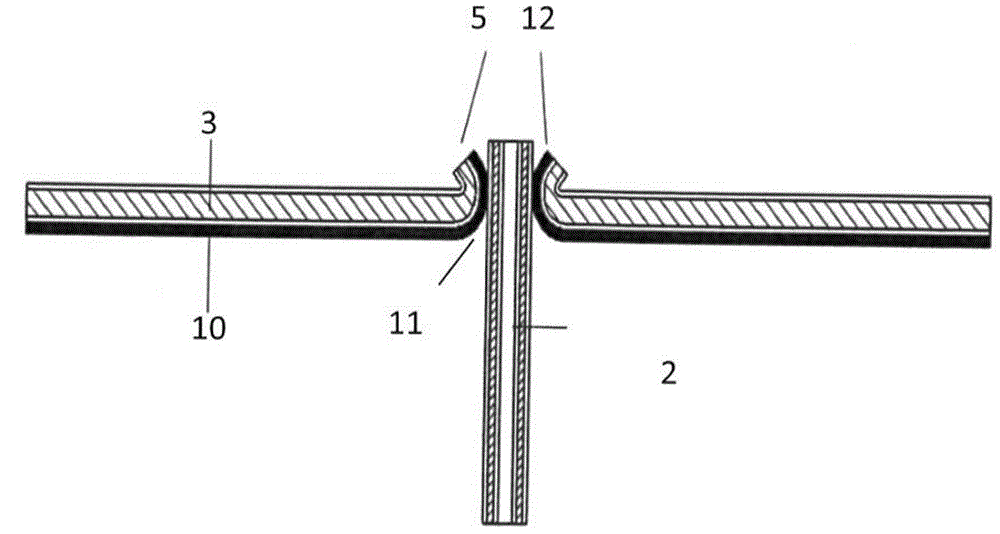

[0024] figure 1 Shown is a heat exchanger 1 , preferably an adsorption heat exchanger, which is formed from a plurality of tubes 2 , for example flat tubes, arranged parallel to one another. Each end of the tube 2 is received by a bottom 3, 4 respectively, wherein each base 3, 4 has a number of beads 5 corresponding to the number of tubes 2, and each end of the tube 2 has a Embedded in one of these curls 5 . The bottom 4 is closed by means of a water tank 6 , which rests on the bottom 3 . The two housing half-shells 8 , 9 surround the composite structure formed by the flat tube 2 and the base 3 , 4 .

[0025] In this heat exchanger with adsorption pump function, the working medium (such as methanol) is driven by temperature in the tube 2 to oscillate from one side of the functional chamber (where the tube 2 is filled with activated carbon) to the other side of the functional chamber. One side (where the tube 2 is provided with cotton rope). The tubes 2 , the bases 3 , 4 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com