A Method for Optimizing the Flow Field of a Medium-Speed Mill

An optimization method and flow field technology, applied in grain processing and other directions, can solve the problems of low separation efficiency of the upper flow field, low separation efficiency, large system resistance, etc. The effect of increasing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

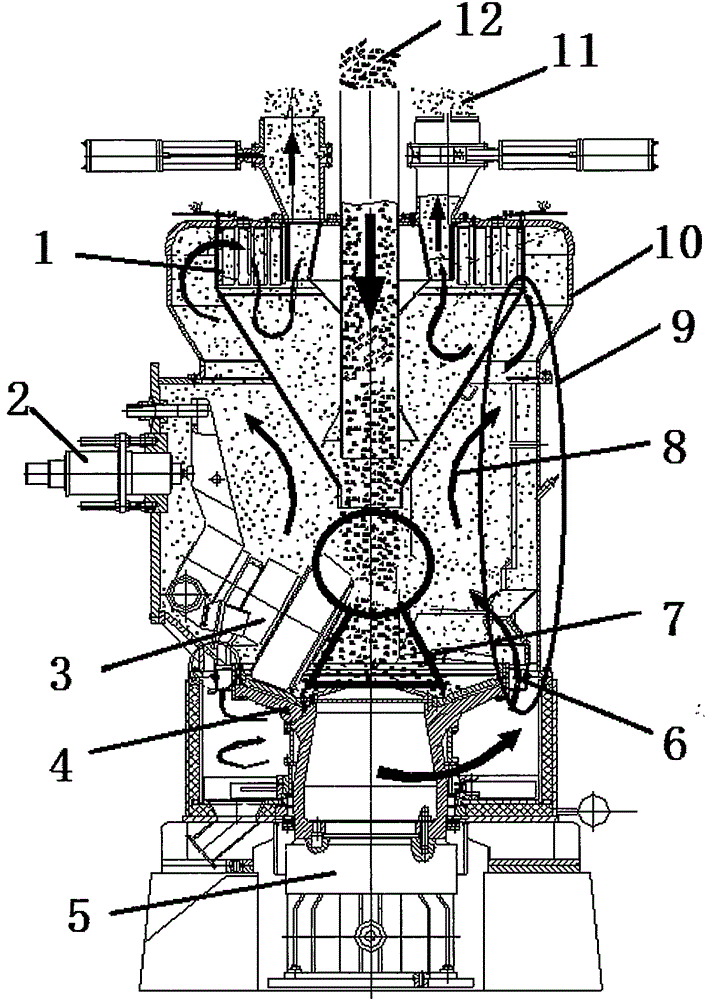

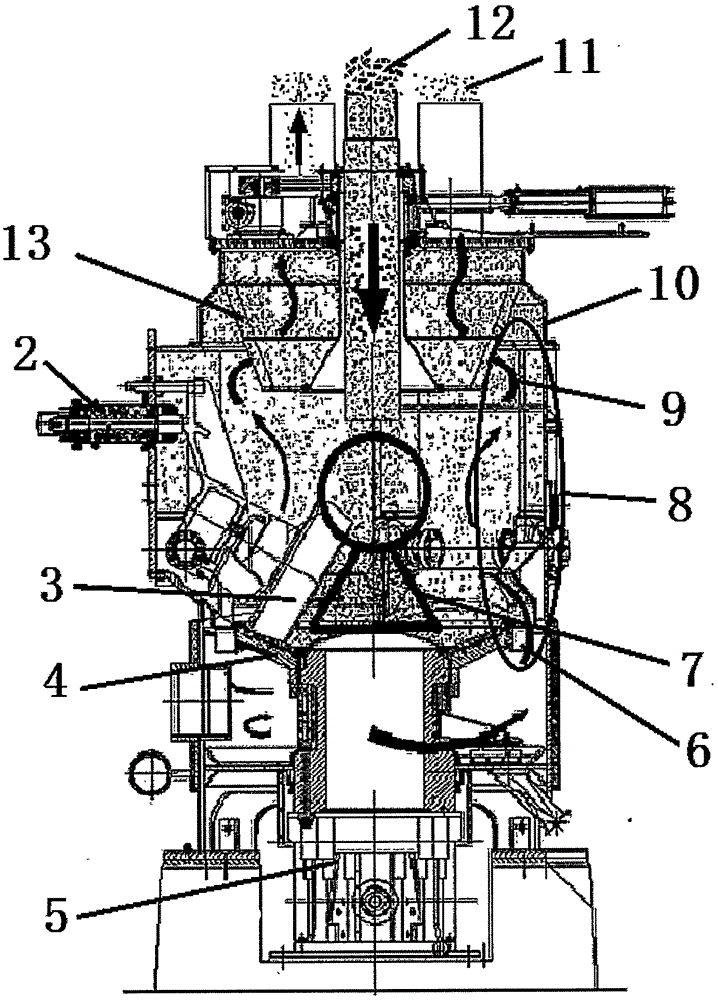

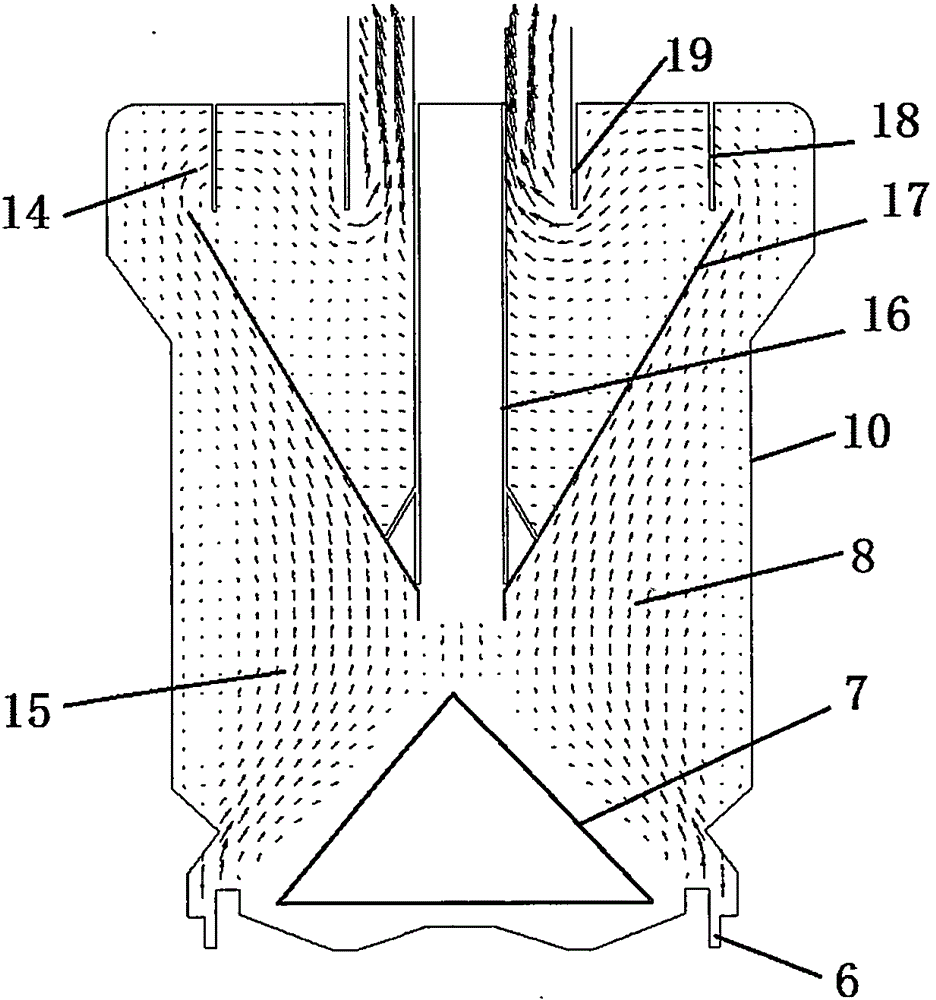

[0049] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0050] The reference signs and components involved in the accompanying drawings are as follows:

[0051] 1-Raymond separator; 2-spring loading device; 3-roller device; 4-disc device; 5-main reducer and motor; 6-annular gap; 7-inert area; Powder conveying and drying module; 10-mill shell; 11-outlet abrasive powder; 12-incoming mill material; 13-traditional dynamic separator; 14-upper flow field; 15-lower flow field; 16-central feed Tube; 17-inner cone; 18-radial blade; 19-exit pipe; 20-rotating airflow; 21-rotating leaf cage; 22-rotating airflow inside leaf cage; 23-rotating airflow outside leaf cage; 24-disc center Air inlet; 25-the airflow of the center air inlet of the millstone; 26-the material layer of the millstone; 27-the airflow of the air inlet pipe above the millstone; 28-the air inlet pipe above the millstone; 29-the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com