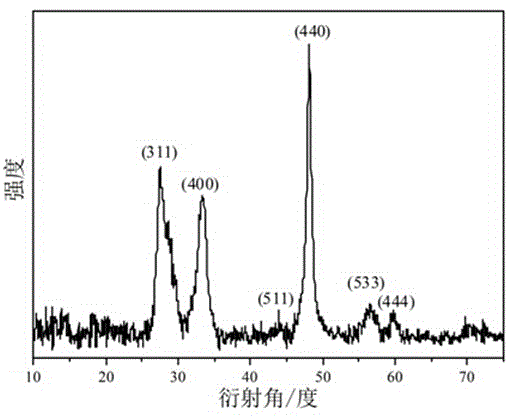

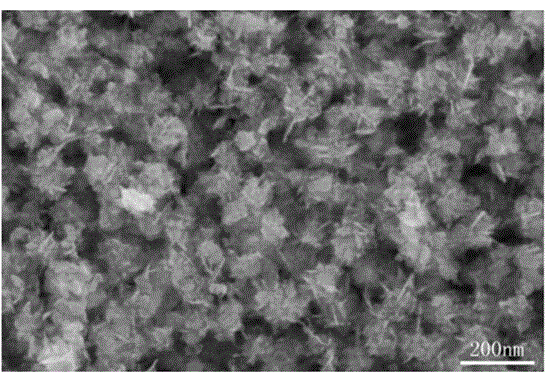

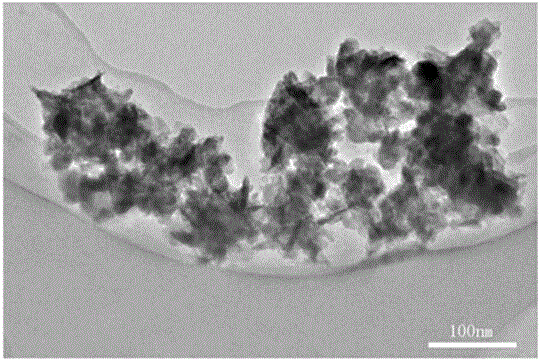

Indium sulfide photocatalyst with hierarchical structures and preparation method thereof

A hierarchical structure, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of sulphur consumption, large environmental pollution, high cost, reduce pollution, and simple experimental methods. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.2 g InNO 3 ·4.5H 2 Dissolve O in 30 mL of deionized water, stir magnetically until all of it is dissolved, and obtain a clear and transparent solution; press S to the above solution 2- : In 3+ Add 0.197 g thioacetamide (CH 3 CSNH 2 ), continue magnetic stirring until it dissolves, at which time the solution becomes light yellow; then add 0.15 g of polystyrene sulfonate (PSS) as a surfactant to the above solution, stir for a while until it dissolves; transfer the above mixed solution to water Then put the hydrothermal kettle in an oven and heat it at a constant temperature of 150°C for 20 hours. After the thermostatic reaction is over, take out the hydrothermal kettle, cool to room temperature and discard the supernatant, and collect the precipitate; Wash the precipitate 2-3 times with deionized water and absolute ethanol to remove impurities in the precipitate; dry the washed precipitate at a constant temperature of 60°C for 10 h to obtain an orange indium sulfide ...

Embodiment 2

[0030] Weigh 0.2 g InNO 3 ·4.5H 2 Dissolve O in 30 mL of deionized water, stir magnetically until all of it is dissolved, and obtain a clear and transparent solution; press S to the above solution 2- : In 3+ Add 0.197 g thioacetamide (CH 3 CSNH 2 ), continue magnetic stirring until it dissolves, at which time the solution becomes light yellow; then add 0.15 g of polystyrene sulfonate (PSS) as a surfactant to the above solution, stir for a while until it dissolves; transfer the above mixed solution to water Then put the hydrothermal kettle in an oven and heat it at a constant temperature of 150°C for 12 h. After the thermostatic reaction is over, take out the hydrothermal kettle, cool to room temperature, discard the supernatant, and collect the precipitate; Wash with deionized water and absolute ethanol for 2-3 times respectively to remove impurities in the precipitate; dry the washed precipitate at a constant temperature of 60°C for 10 h to obtain yellow In 2 S 3 powder.

[0031]...

Embodiment 3

[0033] Weigh 0.2 g InNO 3 ·4.5H 2 Dissolve O in 30 mL of deionized water, stir magnetically until all of it is dissolved, and obtain a clear and transparent solution; press S to the above solution 2- : In 3+ Add 0.197 g thioacetamide (CH 3 CSNH 2 ), continue magnetic stirring until it dissolves, at which time the solution becomes light yellow; then add 0.15 g of polystyrene sulfonate (PSS) as a surfactant to the above solution, stir for a while until it dissolves; transfer the above mixed solution to water Then put the hydrothermal kettle in an oven and heat it at a constant temperature of 120°C for 20 hours. After the thermostatic reaction is over, take out the hydrothermal kettle. After cooling to room temperature, discard the supernatant and collect the precipitate; Wash with deionized water and absolute ethanol for 2-3 times respectively to remove impurities in the precipitate; dry the washed precipitate at a constant temperature of 60°C for 10 h to obtain yellow In 2 S 3 pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com