Preparation method of empagliflozin microcrystalline cellulose composition

A technology of microcrystalline cellulose and empagliflozin, applied in the field of medicine, can solve problems such as complicated production, increased contact area between production workers and drugs, explosion, etc., and achieve cost saving and production time, good in vitro dissolution behavior, and preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

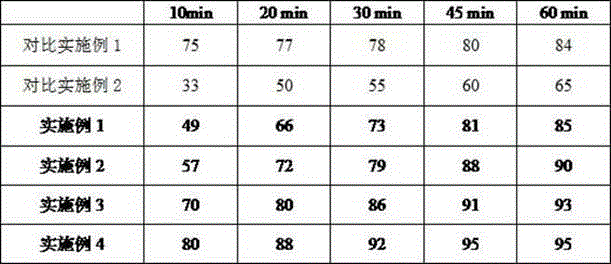

Embodiment 1

[0034] The preparation of Empagliflozin microcrystalline cellulose composition:

[0035] Weigh 10g of empagliflozin and 20g of microcrystalline cellulose and mix them into a jacketed granulator for granulation. The temperature is set at 160°C, stirred for 15 minutes, taken out and cooled, and passed through a 20-mesh sieve.

Embodiment 2

[0037] The preparation of Empagliflozin microcrystalline cellulose composition:

[0038] Weigh 10g of Empagliflozin and 50g of microcrystalline cellulose, mix them into a jacketed granulator for granulation, set the temperature at 200°C, stir for 5 minutes, take it out and cool it, and use a rotating granulator with an aperture of 1.0mm Machine can be granulated.

Embodiment 3

[0040] The preparation of Empagliflozin microcrystalline cellulose composition:

[0041] Weigh 10g of empagliflozin and 100g of microcrystalline cellulose and mix them into a jacketed granulator for granulation. The temperature is set at 170°C, stirred for 15 minutes, taken out and cooled, and passed through a 30-mesh sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com