Cable butting connector

A docking connector and cable docking technology, applied in the direction of cable joints, etc., can solve the problems of troublesome assembly and disassembly operations, poor waterproof and airtight performance, and affect the overall appearance of cables, etc., to achieve good sealing and waterproof effects, fast and convenient assembly and disassembly , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

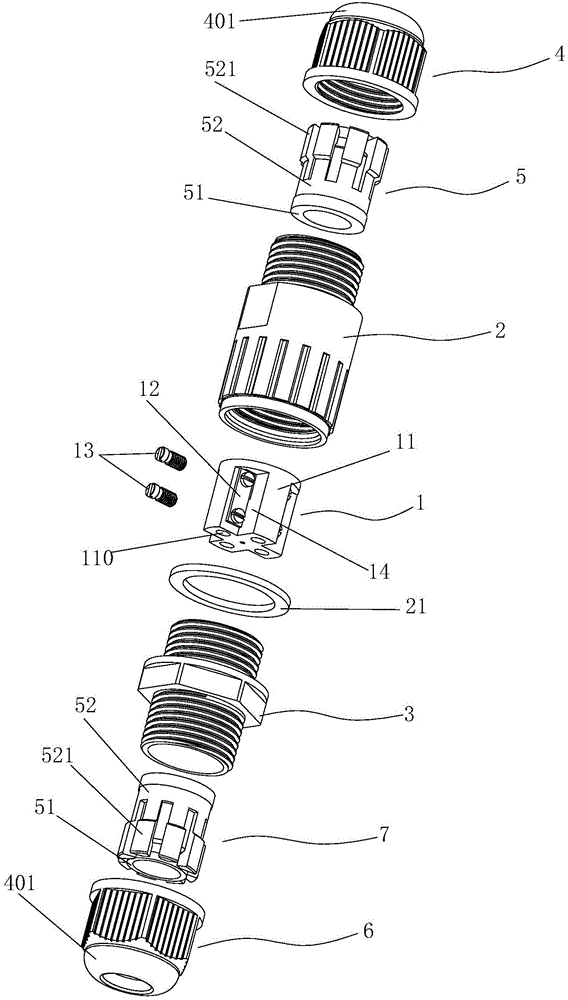

[0012] Such as figure 1 As shown, the present invention is a cable butt connector, the butt connector has an integrally formed columnar plastic connection seat body 1, and several wire butt hole seats distributed in a circumferential shape are formed on the connection seat body 1 11. Each wire docking hole seat 11 is provided with a wire docking hole 110 parallel to the axis 11 of the connection seat body. Each wire docking hole 110 is fixed with a copper guide seat 12, and the copper guide seat 12 has a wire docking hole 110 Coaxial wire hole, the radial direction of the copper guide seat 12 is also connected with the locking screw 13 passing through the wire hole and the wire docking hole seat 11; on the connecting seat body 1, the outer side of each wire docking hole seat 11 is formed There is a avoiding part 14 for avoiding the locking screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com