Fully-insulated and fully-sealed solid-cabinet fuse tube

A fully sealed and fuse cartridge technology, applied in the direction of switchgear, electrical components, circuits, etc., can solve the problems of large product volume, high extrusion force, and inability to satisfy users in different regions, achieve uniform electric field distribution, and solve partial amplification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

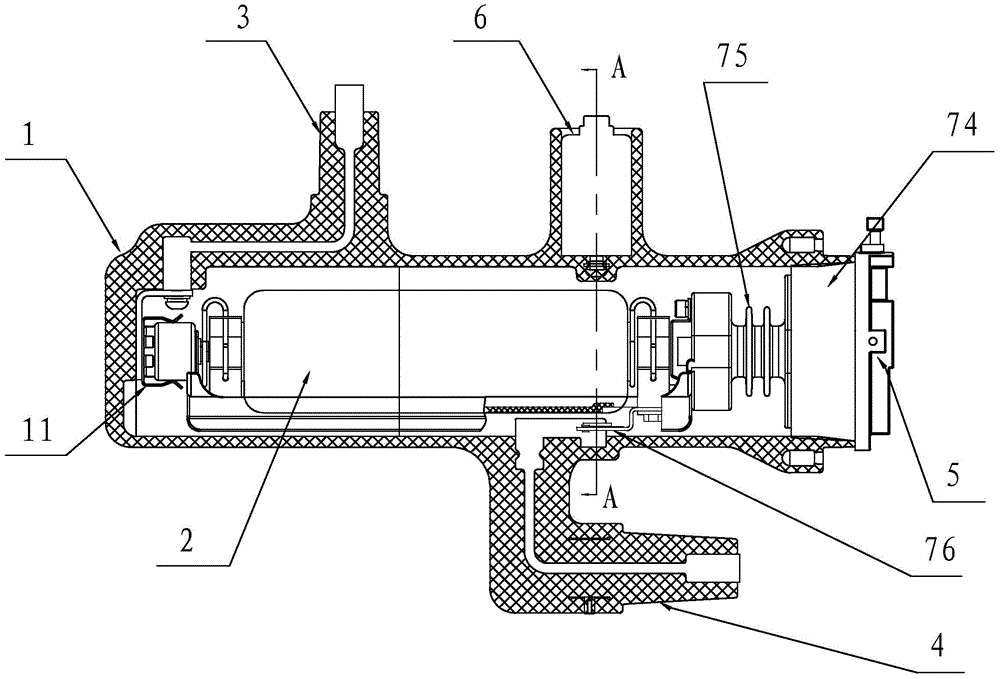

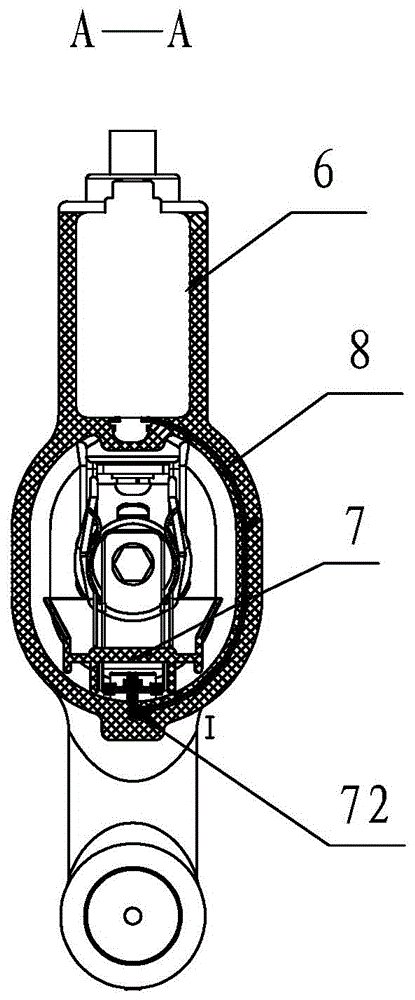

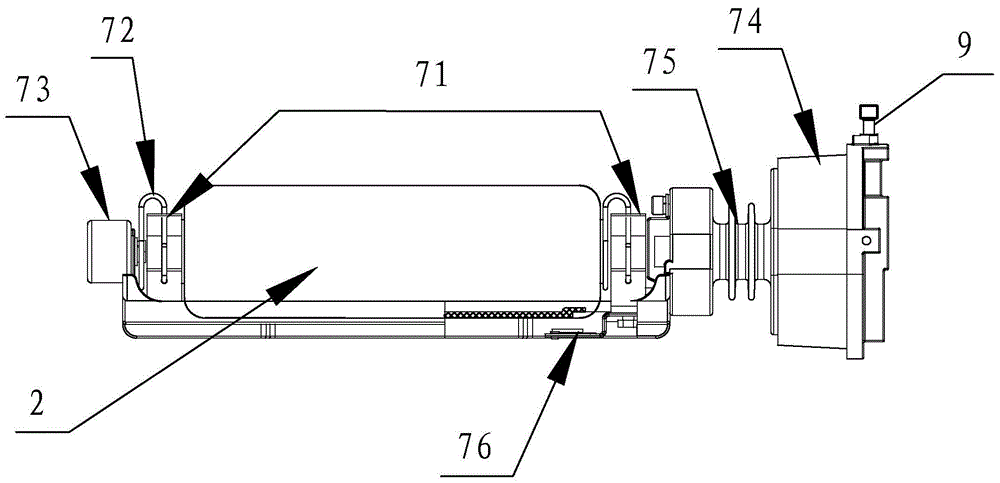

[0027] refer to Figure 1~Figure 4 , the fully insulated and fully sealed solid cabinet fuse cartridge of the present invention includes a fuse cartridge body 1, a fuse 2 installed in the fuse cartridge body 1, an incoming line port 3 connected to a pole, an outgoing cable sleeve 4, The fuse cartridge cover assembly 5 and the grounding vacuum interrupter 6, the auxiliary grounding adopts a vacuum interrupter with mature technology to achieve grounding, which can meet the requirements of small size and full sealing of the fuse cartridge, and the protection level can reach IP67 at the same time, and is not subject to Influenced by the external temperature, and the inlet port 3, the outlet cable casing 4 and the grounding interrupter 6 are packaged on the fuse cartridge body 1 and form three independent spaces, which can make the structural electric field evenly distributed, and the three parts It will not affect each other, and solves the problem of local amplification caused b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com