A high voltage power battery

A power battery, high-voltage technology, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, secondary batteries, etc., can solve the problems of limited conductivity of cylindrical batteries, poor heat resistance of square batteries, violent vibration and even collisions, etc. Achieve the effects of avoiding electrolyte leakage or contact with air, reducing battery internal resistance, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

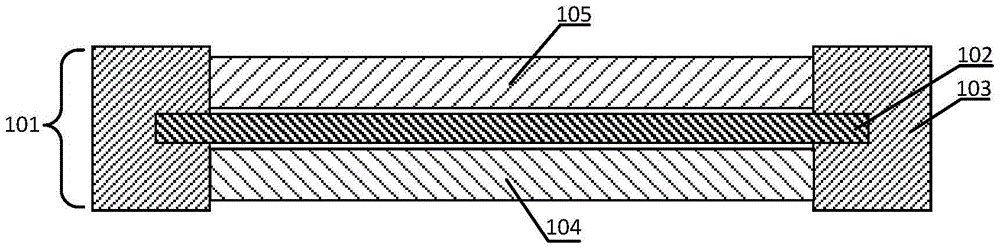

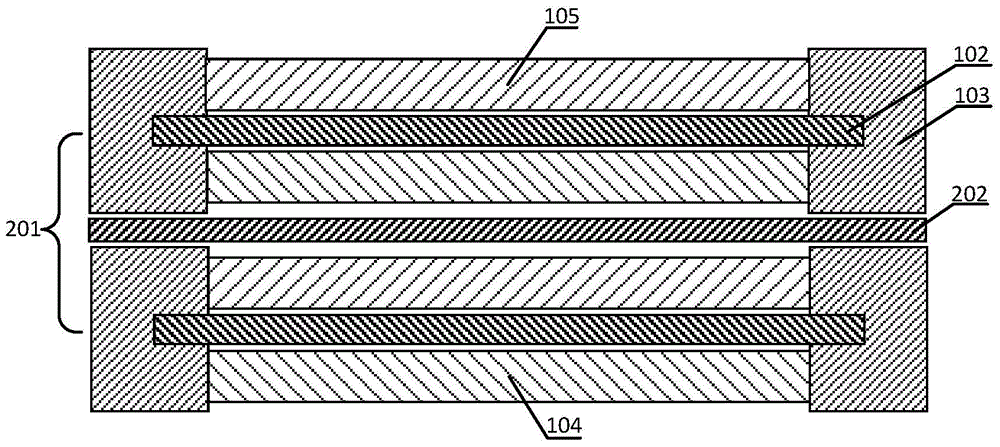

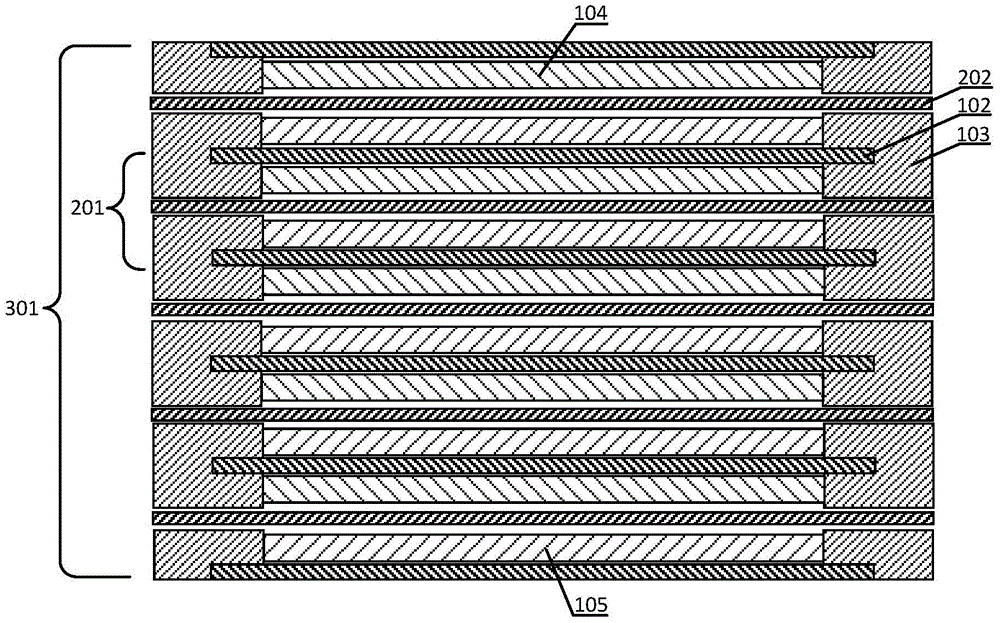

[0046] This embodiment provides a high-voltage power lithium-ion battery.

[0047] The medium and high voltage power lithium-ion battery 801 of the present invention is designed to meet the power supply requirements of various electric vehicles. Therefore, according to the different application occasions of the battery, the voltage design value of the battery cell 301 is also different. The number of stacks varies. At present, the working voltages of small electric vehicles (including electric bicycles, electric motorcycles and electric sightseeing cars, etc.) are generally: 36V, 48V, 64V, 74V and 80V. Large and medium-sized electric vehicles (including pure electric crew cars, pure electric trucks, etc.) , hybrid vehicles, electric buses, etc.) operating voltage range is generally 120V ~ 500V.

[0048] This embodiment is a pure electric passenger car power supply, its working voltage is 360V, the working voltage platform of the selected battery cell 301 is 360V, and the numb...

Embodiment 2

[0059] This embodiment provides an elastic gasket 401 device for a high-voltage power battery.

[0060] In this embodiment, the elastic gasket 401 includes a circular gasket 402 and an elastic body 403a, wherein the elastic body is an elastic porous metal nickel foam, such as Figure 4 As shown in a, or it is a metal sheet with compressive resilience such as wave board wave, cup board, etc., such as Figure 4 b and Figure 4 c shown. The rest of the structure of the battery is the same as that of the first embodiment.

Embodiment 3

[0062] This embodiment provides a flexible current collector 601 device for a high-voltage power battery.

[0063] In this embodiment, various arrangements of the flexible current collecting wires 601 on the battery case are listed, such as Figure 7 a. Figure 7 b. Figure 7 c and Figure 7 d, respectively (a) single-spiral flexible collector line; (b) multi-spiral flexible collector line; (c) strip-shaped flexible collector line; (d) polygonal mesh flexible collector line; The material is copper and aluminum alloy with silver plated surface. The rest of the structure of the battery is the same as that of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com