Preparation method of solid oxide fuel cell gradient structure cathode film

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, battery electrodes, structural parts, etc., can solve problems such as large polarization loss, achieve the effects of reducing interface impedance, simplifying sintering process, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

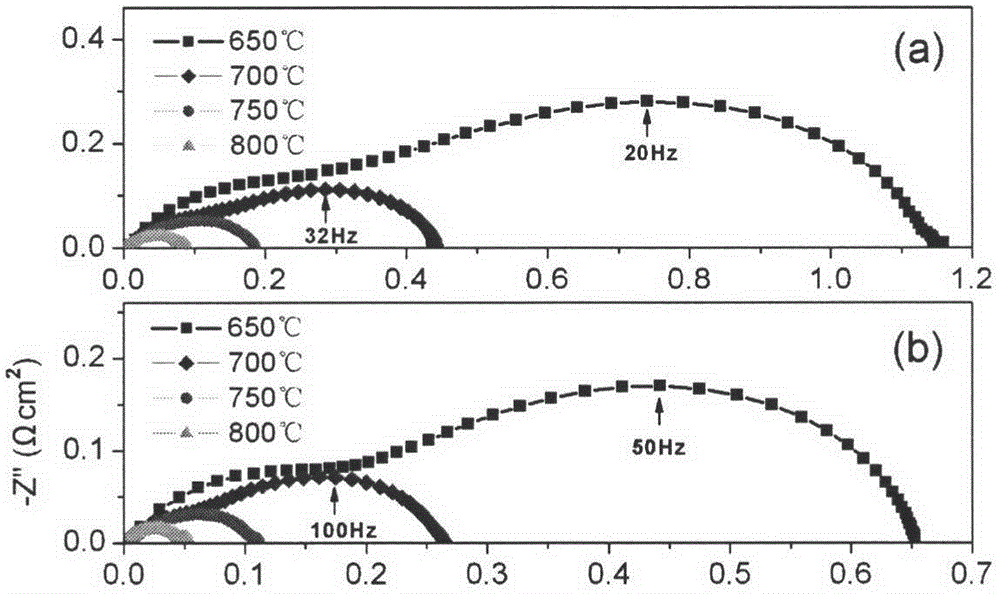

Image

Examples

Embodiment 1

[0039] 1. Synthesis of LSCF powders with different particle sizes

[0040] Take La(NO 3 ) 3 ·6H 2 O, Sr(NO 3 ) 2 , Co(NO 3 ) 3 and Fe(NO 3 ) 3 9H 2 O as a raw material, La was synthesized by a sol-gel method 0.6 Sr 0.4 co 0.2 Fe0.8 o 3 (LSCF) powder, the particle size of the powder obtained after full ball milling and dispersion is 0.1-0.3 μm; 2 o 3 , SrCO 3 , CoCO 3 and Fe 2 o 3 As raw material, (LSCF) powder was synthesized by gel injection molding process, and the particle size of the synthesized powder was 0.6-1 μm; La 2 o 3 , SrCO 3 , CoCO 3 and Fe 2 o 3 As a raw material, the particle size of LSCF powder is synthesized by a solid-state method with a particle size of 1-2 μm.

[0041] 2. Slurry Preparation

[0042] (1) Use LSCF powder with a particle size of 0.1-0.3 μm to form a mixed powder with pore-forming agent graphite in a mass ratio of 1:0.1, add organic solvent ethanol and dispersant, ball mill for 20 hours, and then add plasticizer, After...

Embodiment 2

[0058] Embodiment 2: As described in Embodiment 1, the difference is that the gradient cathode material is strontium manganate lanthanum La x Sr 1-x MnO 3-δ (LSM), the sintering temperature is 1100°C, and it is kept for 2 hours and naturally cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com