Electrode structure, manufacturing method thereof, display substrate and display device

A technology of electrode structure and manufacturing method, which is applied in the direction of circuits, electrical components, and electric solid devices, can solve problems such as poor mechanical strength and flexibility, large square resistance, and increased power consumption of flexible display devices, achieving low square resistance, The effect of satisfying the requirement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

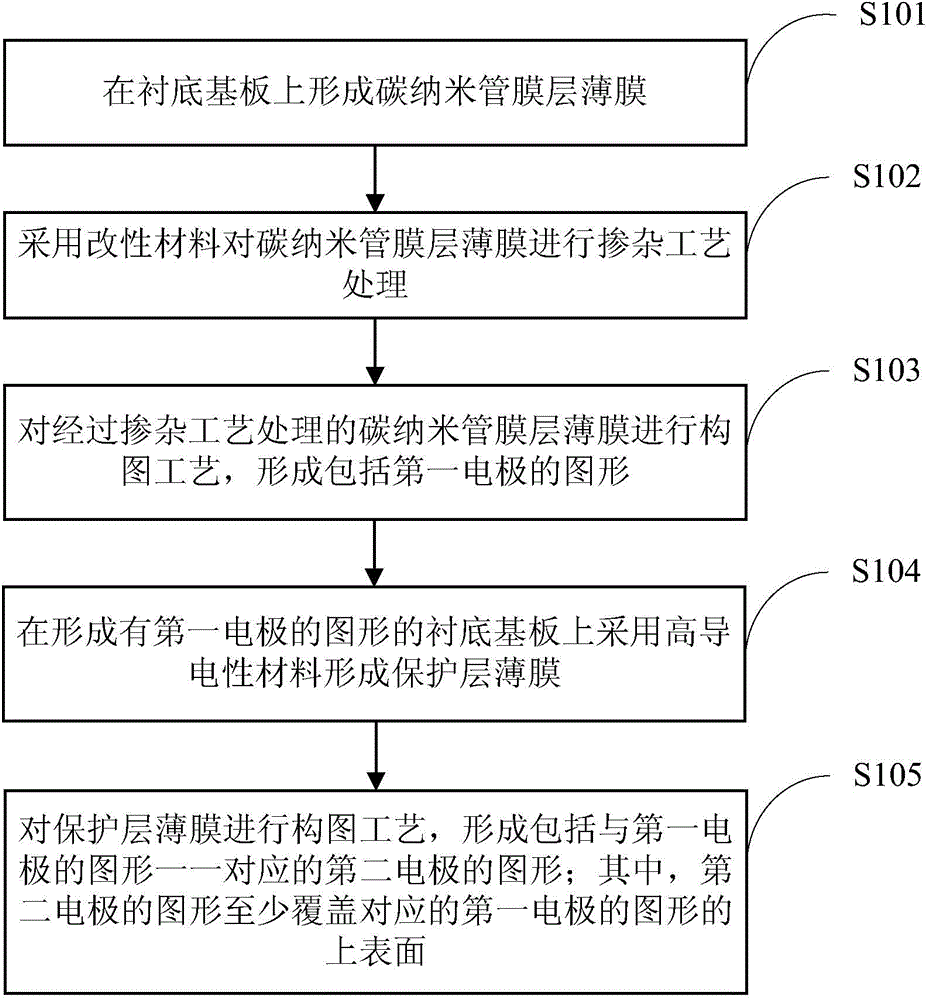

[0062] Example 1: The fabrication method of the electrode structure provided by the embodiment of the present invention, such as figure 1 As shown, it specifically includes the following steps:

[0063] S101, forming a carbon nanotube film on the substrate;

[0064] S102, using a modified material to perform a doping process on the carbon nanotube film;

[0065] S103 , performing a patterning process on the carbon nanotube film treated by the doping process to form a pattern including the first electrode.

[0066] The above-mentioned method provided by Example 1 of the present invention can ensure that the first electrode formed after the patterning process has a lower square resistance value by doping modified materials in the carbon nanotube film layer film. Therefore, using the method provided by Example 1 of the present invention The first electrode fabricated by the above method can meet the conductivity requirement of the flexible display for the flexible electrode. ...

example 2

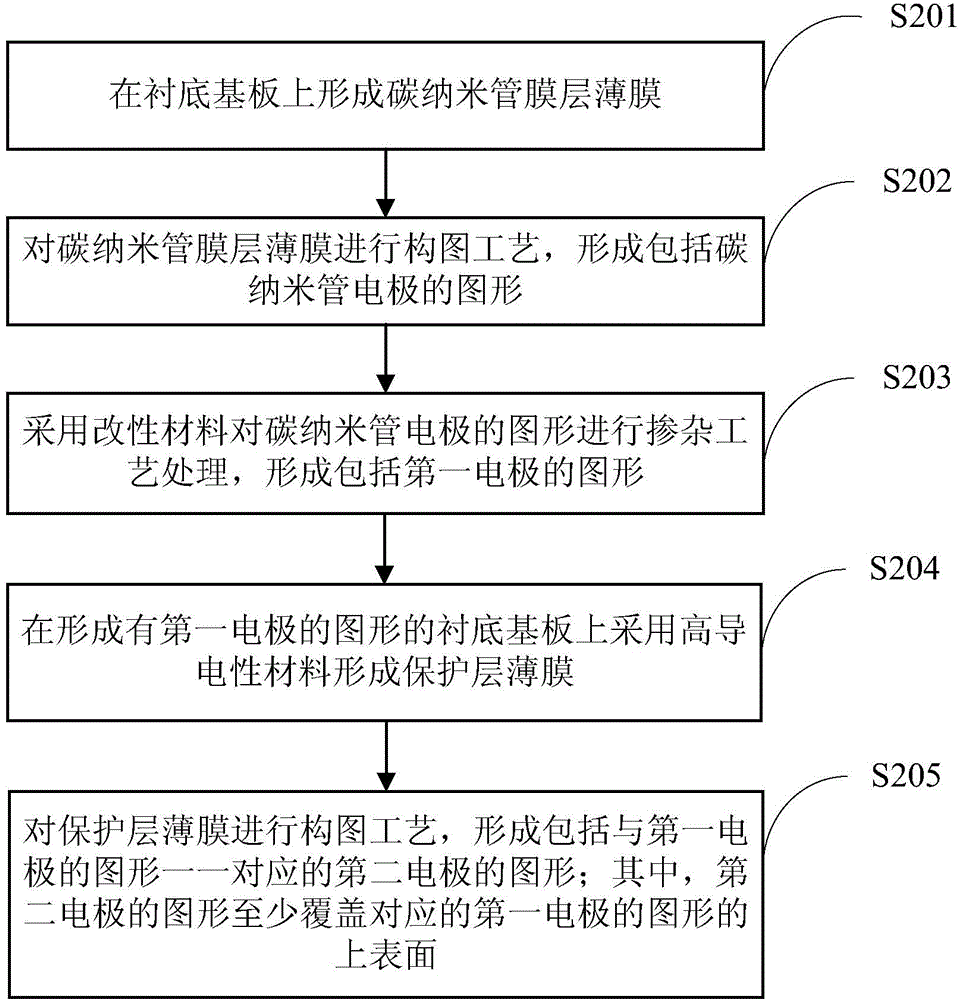

[0089] Example 2: The fabrication method of the electrode structure provided by the embodiment of the present invention, such as figure 2 As shown, it specifically includes the following steps:

[0090] S201, forming a carbon nanotube film on the base substrate;

[0091] S202, performing a patterning process on the carbon nanotube film layer to form a pattern including carbon nanotube electrodes;

[0092] S203. Perform a doping process on the pattern of the carbon nanotube electrode by using a modified material to form a pattern including the first electrode.

[0093] The above-mentioned method provided by Example 2 of the present invention can ensure that the formed first electrode has a lower square resistance value by doping modified materials in the pattern of the carbon nanotube electrode. Therefore, the above-mentioned method provided by Example 2 of the present invention is used to make The first electrode can meet the requirements of flexible display on the conducti...

example 3

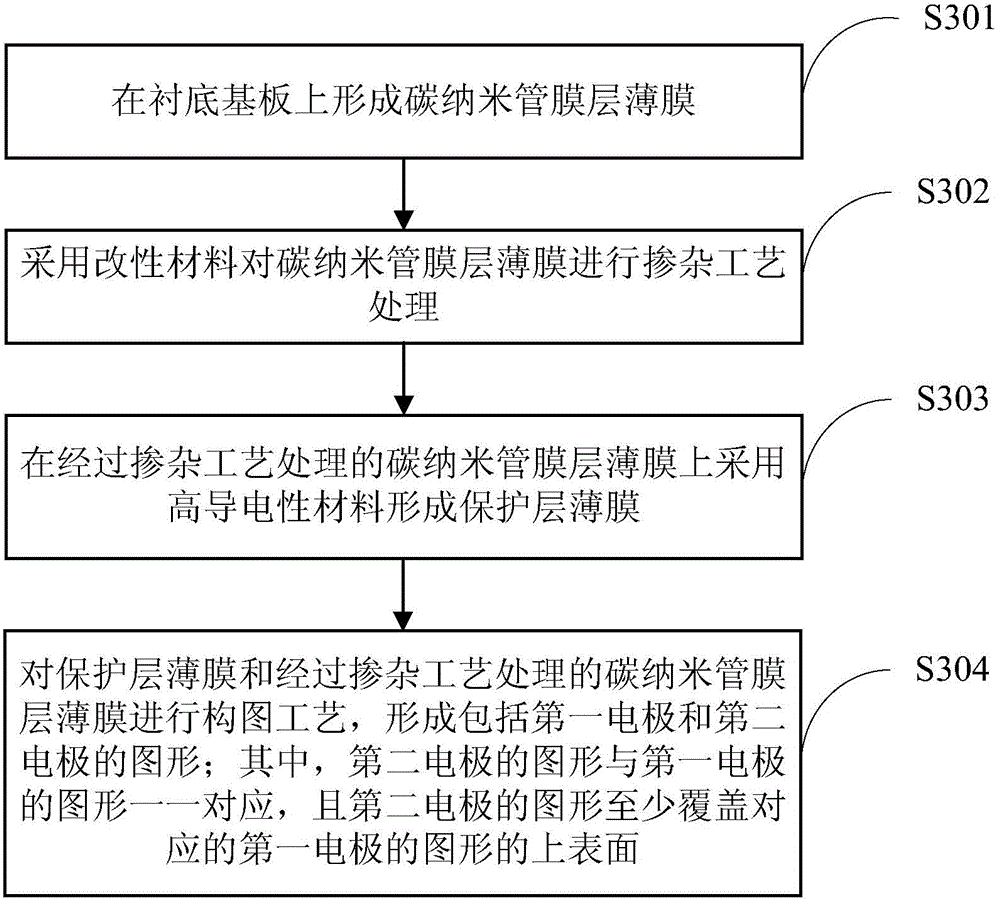

[0101] Example 3: The fabrication method of the electrode structure provided by the embodiment of the present invention, such as image 3 As shown, it specifically includes the following steps:

[0102] S301, forming a carbon nanotube film on the substrate;

[0103] S302, using a modified material to perform a doping process on the carbon nanotube film;

[0104] S303, forming a protective layer film on the carbon nanotube film film treated by a doping process by using a high-conductivity material;

[0105] S304. Perform a patterning process on the protective layer film and the carbon nanotube film layer film treated by the doping process to form a pattern including the first electrode and the second electrode; wherein, the pattern of the second electrode and the pattern of the first electrode are one by one corresponding, and the pattern of the second electrode covers at least the upper surface of the pattern of the corresponding first electrode; that is, the second electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com