High polymer transparent conductive film and preparation method thereof

A technology of polymer transparent and conductive film, applied in conductive coatings, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problems of insufficient flexibility and poor adhesion of transparent conductive films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] According to another aspect of the present invention, there is also provided a method for preparing a polymer transparent conductive film, which includes the following steps: forming a conductive layer 200 on the resin base layer 100, and the conductive layer 200 has a plurality of resin base layers 100 the exposed gap 201 ; and forming a resin fixing layer 300 on the conductive layer 200 and the gap 201 .

[0046] In the polymer transparent conductive film formed by this method, a thin resin fixing layer 300 is provided on the conductive layer 200 . The resin fixed layer 300 has high flexibility, which can effectively improve the flexibility of the entire polymer transparent conductive film. At the same time, since the thickness of the resin fixed layer 300 is sufficiently thin, the conductive filler located in the conductive layer 200 can be exposed from the resin fixed layer 300 , so that the polymer transparent conductive film maintains high conductivity. More impo...

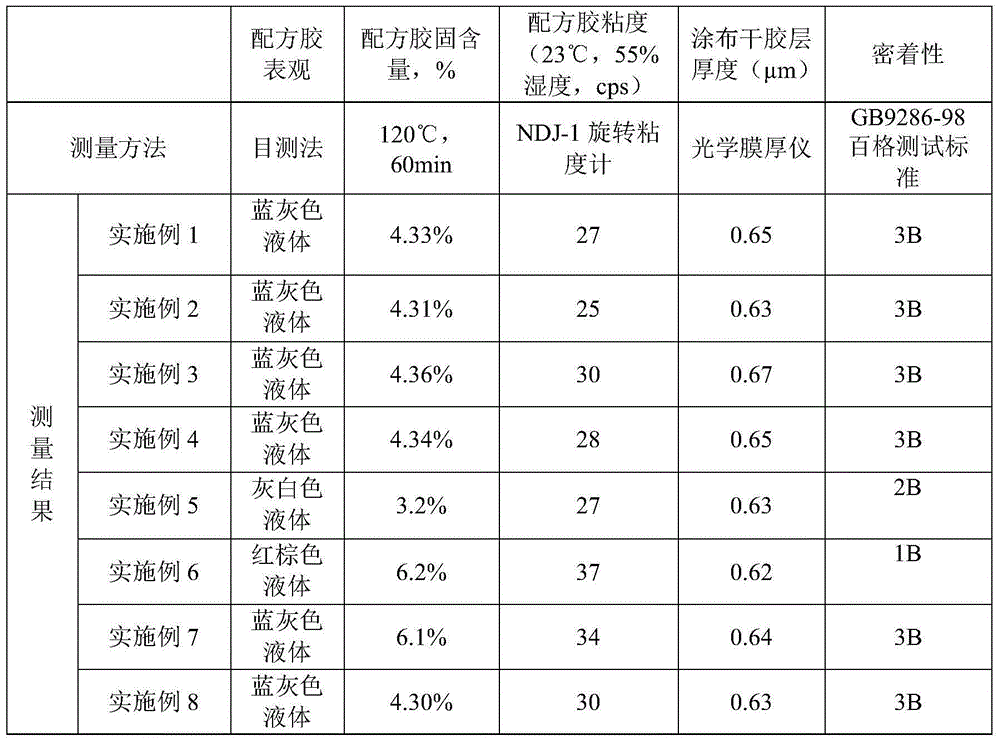

Embodiment 1

[0055] In a 50ml beaker, add 10g PEDOT / PSS dispersion liquid ICP1010 (AGFA company), 1.2g WD201 nano-silver wire slurry (concentration: 3mg / ml, Chuangke Microelectronics Materials Co., Ltd.), 0.02g BYK333 (manufactured by BYK) in sequence, After the addition, stir with a magnetic stirring rotor for 10 min. After stirring evenly, let it stand for more than 10 minutes to defoam naturally, and then obtain a polymer transparent conductive adhesive;

[0056] Put 5g polyurethane acrylate oligomer 6101 (manufactured by Changxing Chemical Co., Ltd.), 2g propoxylated neopentyl glycol diacrylate EM2251 (manufactured by Changxing Chemical Co., Ltd.), 0.04g BYK378 (manufactured by BYK Chemical Co., Ltd.), 0.32 g photoinitiator 184 (manufactured by Tianjin Jiuri Chemical Co., Ltd.), 177g ethyl acetate and 177g propylene glycol methyl ether, after feeding, stir with a rotating speed of 600rpm for 30min, let it stand for more than 30min to naturally defoam, and the resin fixed layer can be o...

Embodiment 2

[0060] In a 50ml beaker, add 10g of PEDOT / PSS dispersion liquid ICP1020 (AGFA company), 1.9g of carbon nanotube dispersion slurry NTW2300 (Cold Stone Technology), 0.02g of BYK333 in sequence, stir with a magnetic stirring rotor for 10min after adding, and wait for stirring After uniformity, let it stand for more than 10 minutes to defoam naturally, and then obtain a polymer transparent conductive adhesive;

[0061] Put 5g polyurethane acrylate oligomer 6113 (manufactured by Changxing Chemical Co., Ltd.), 2g triethylene glycol dimethacrylate EM328 (manufactured by Changxing Chemical Co., Ltd.), 0.04g BYK378 (manufactured by BYK Chemical Co., Ltd.), 0.32 g photoinitiator 184 (manufactured by Tianjin Jiuri Chemical Co., Ltd.), 177g ethyl acetate and 177g propylene glycol methyl ether, after feeding, stir with a rotating speed of 600rpm for 30min, let it stand for more than 30min to naturally defoam, and the resin fixed layer can be obtained Formula glue;

[0062] Scrape-coat the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com