Full-automatic smelting control system and control method for polycrystalline silicon

A control system, polysilicon technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc., can solve the problems of inability to fully guarantee product quality, high labor intensity, and low control accuracy. , to achieve the effect of low scrap rate, reduced labor intensity, and reduced safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

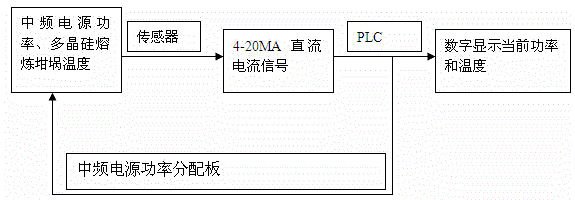

[0013] control figure 1 , polysilicon automatic smelting control system, its structure includes programmable logic controller PLC, intermediate frequency power distribution board, polysilicon melting crucible temperature device, digital display current power and temperature device, sensor, 4-20MA current signal generator; The first signal output end of the programmable controller PLC is connected to the signal input end of the polysilicon melting crucible temperature device through the intermediate frequency power distribution board, and the second signal output end of the programmable logic controller PLC is connected to the signal of the digital display current power and temperature device The input terminal, the signal output terminal of the intermediate frequency power supply and the temperature device of the polysilicon melting crucible are connected to the 4-20MA current signal generator through the sensor, and the signal output terminal of the 4-20MA current signal gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com