Special-shape missile bay section connecting structure for sectional fairing deploying

A technology for connecting structures and missile compartments, applied to self-propelled bombs, weapon types, projectiles, etc., can solve the problems of inconsistent joints, poor workmanship, and inability to prevent loosening of threads, and achieve easy manufacturing process and good load-bearing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

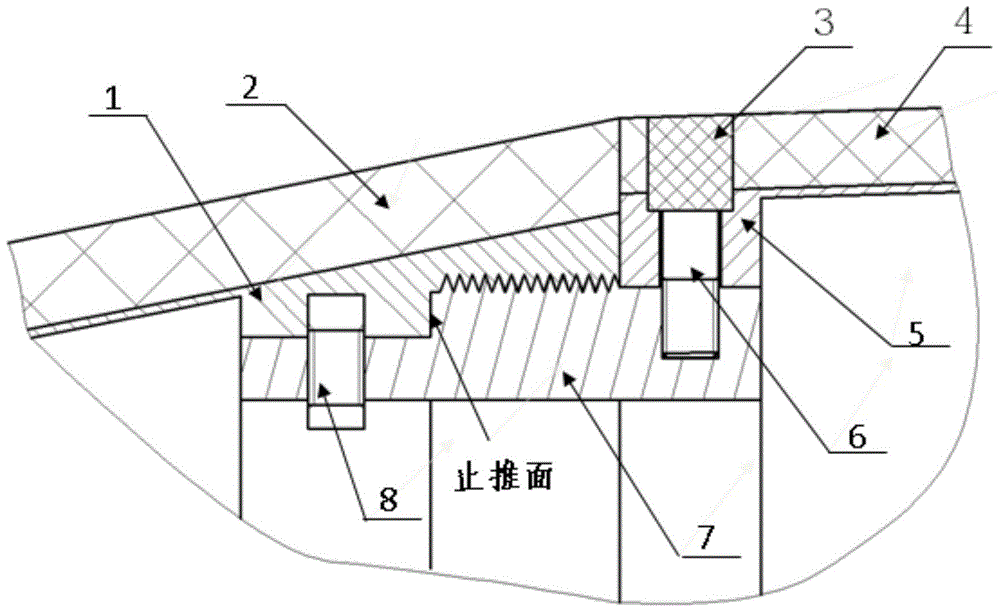

[0015] As shown in Figure 1, a special-shaped missile cabin section connection structure suitable for split-flap throwing covers includes a guide cabin metal shell 1, a warhead cabin metal shell 5, and a cabin body adapter ring 7, wherein, There is a threaded structure on the inner wall of the right side edge of the metal shell 1 of the pilot cabin that covers the heat-proof layer 2 of the pilot cabin, and the left side of the thread structure end of the metal shell 1 of the pilot cabin is a raised structure, forming a stop at the end of the thread. The push surface, and two anti-loosening holes are opened on the raised structure; the cabin body adapter ring 7 is a stepped cylindrical structure, and the diameter of the left side of the cylinder wall is small, and it is raised with the metal shell 1 of the guide cabin. The structure ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com