Mechanical arm tail end executing device

A technology of end effector and robotic arm, which is applied in the field of automation, can solve the problems of large size, large occupied space, and inflexibility of the end of the robotic arm, and achieve the effect of compact structure, small occupied space, and wide range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

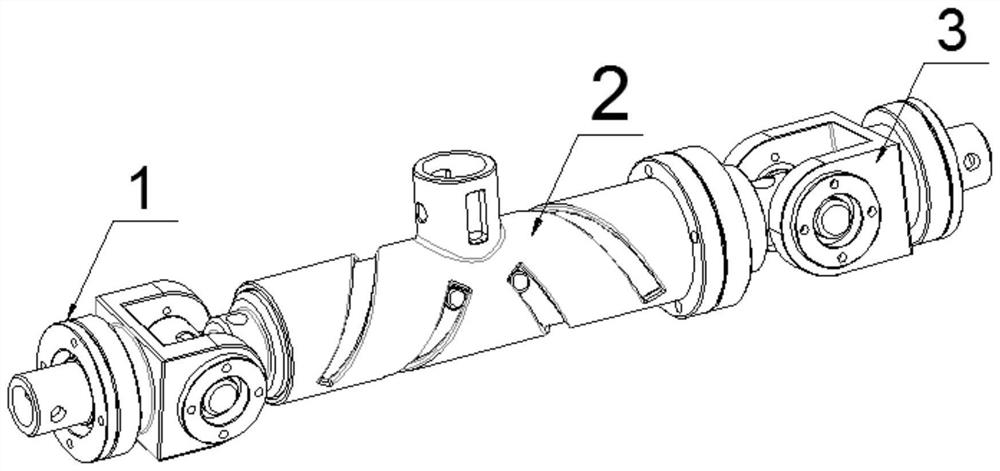

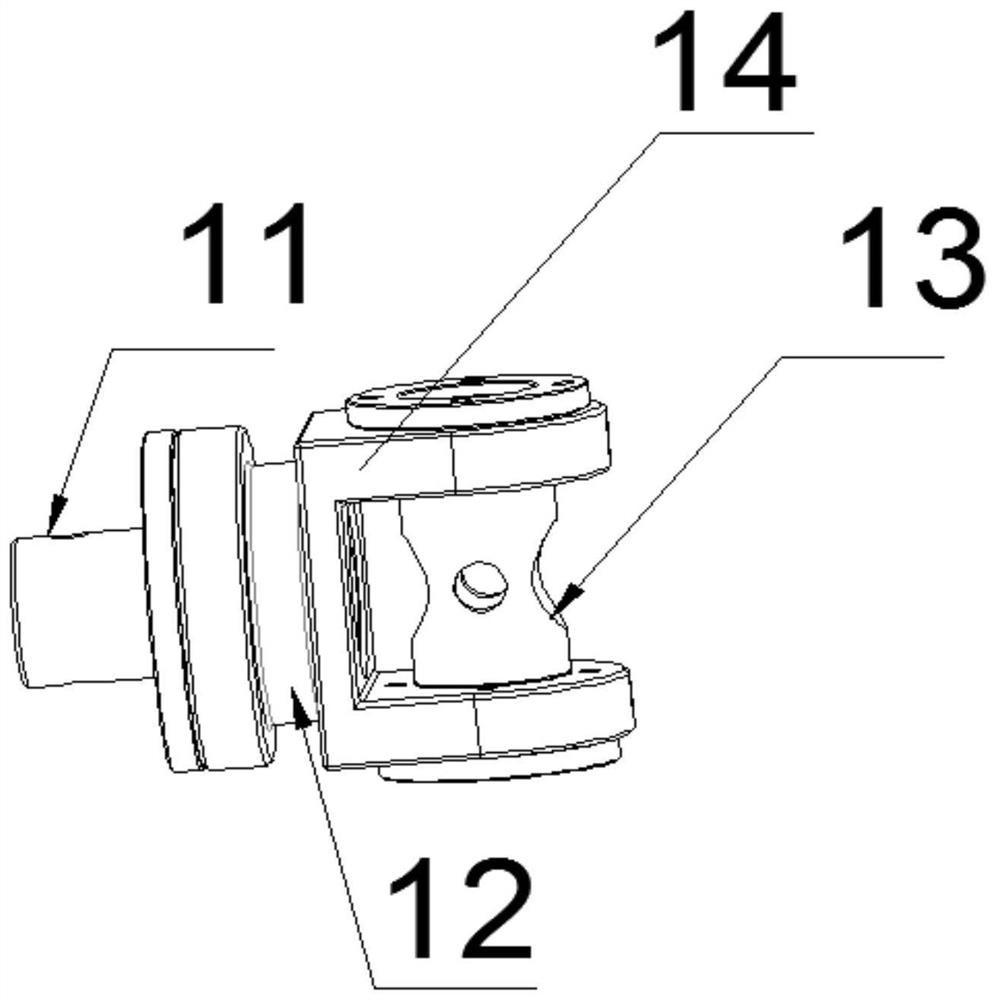

[0022] Such as figure 1 As shown in -4, a mechanical arm end effector includes a Hooke joint 1, a ball joint 3 and a connecting sleeve 2; the Hooke joint 1 and the ball joint 3 are installed on the connecting sleeve 2 Both ends; the connecting sleeve 2 includes a Hooke hinge side connecting rod 21, a ball hinge side connecting rod 22, a fastening flange 23, a support sleeve 24 and an intermediate connecting rod 25; the Hooke hinge side connecting rod 21 and the ball hinge side connecting rod 22 are respectively mounted on the left and right ends of the support sleeve 24, the middle part of the support sleeve 24 is hollow, and several spiral through holes 26 are set on the support sleeve 24, the tiger The tail ends of the hinge side connecting rod 21 and the ball hinge side connecting rod 22 are provided with rotating pins 27, and the rotating pins 27 are clamped in the spiral through holes 26, and the intermediate connecting rod 25 is installed in the supporting sleeve 24. Th...

Embodiment 2

[0026] The Hooke joint 1 and the ball joint 3 are slidably connected to the left and right ends of the connecting sleeve 2, the intermediate connecting rod 25 is slidably installed inside the support sleeve 24, and one end of the intermediate connecting rod 25 is connected to Hooke joint 1, the other end is connected to ball joint 3.

Embodiment 3

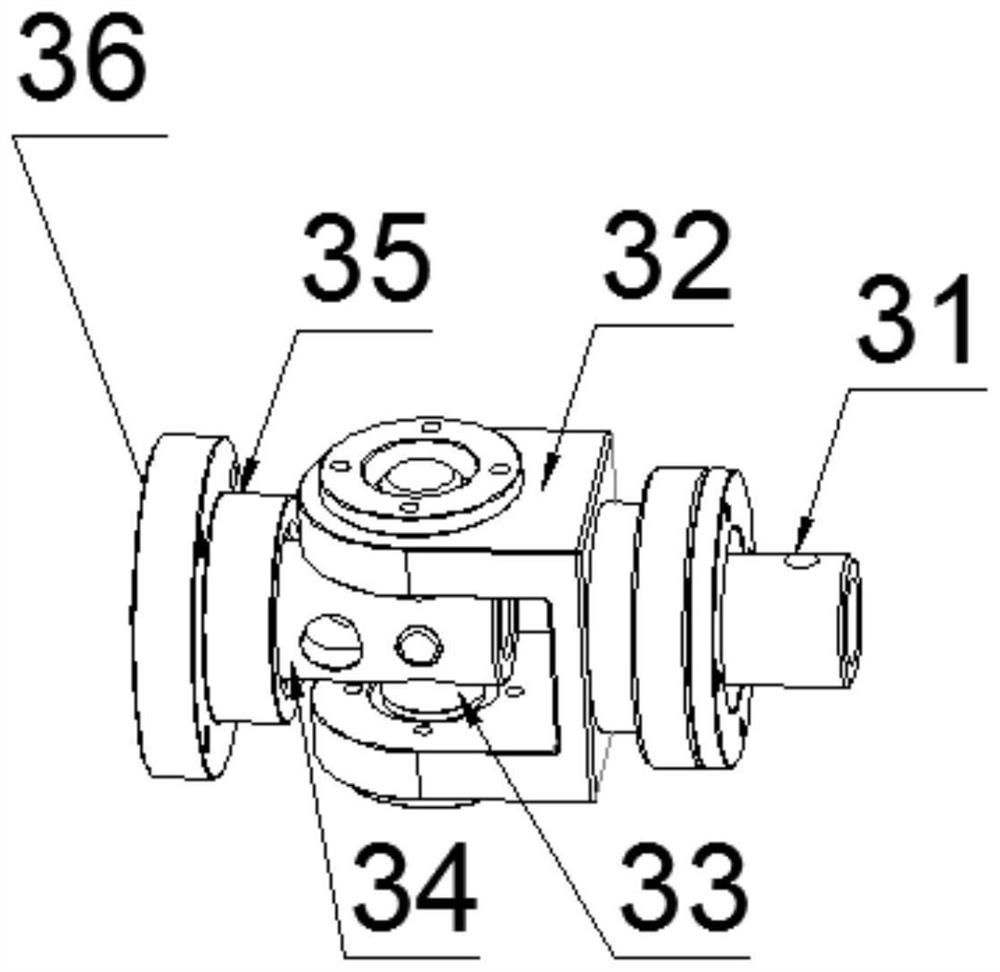

[0028] On the basis of Embodiment 1, the ball joint 3 includes a ball joint rotating rod one 31, a ball joint rotating shaft seat 32, a ball joint intermediate shaft 33, a ball joint rotating rod two 34, a ball joint rotating sleeve 35 and a fastening method Lan 2 36; the fastening flange 2 36 is fixedly socketed with the ball hinge sleeve 35, and the ball hinge sleeve 35 is sleeved on the ball head rotation rod 2 34, and the ball hinge shaft seat 32 passes through the ball hinge The intermediate rotating shaft 33 is rotationally connected with the ball joint rotating rod two 34, and one side of the ball joint rotating shaft seat 32 is provided with a rotating shaft bearing, and the described ball joint rotating rod one 31 is rotationally connected on the rotating shaft bearing to realize three-degree-of-freedom motion.

[0029] The second fastening flange 36 is fixedly connected with the first fastening flange 23 by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com